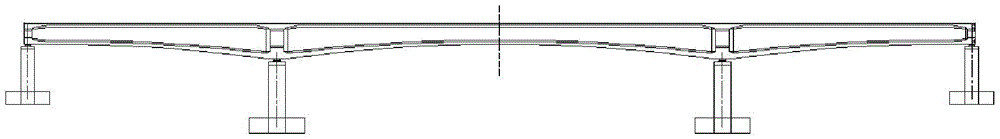

A kind of cable-stayed bridge structure and construction method for strengthening psc continuous box girder bridge

A cable-stayed bridge and box girder technology, applied in cable-stayed bridges, bridge reinforcement, bridges, etc., can solve problems such as insufficient bearing capacity, hidden dangers, and insufficient bearing capacity of bridges, and achieve less space occupation, practicability guarantee, and improved Anti-bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

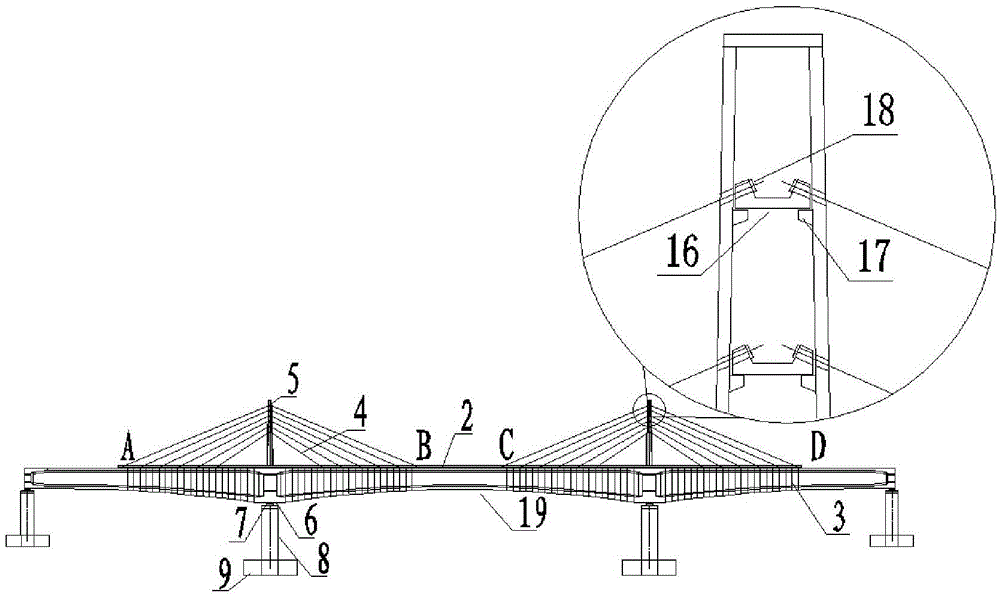

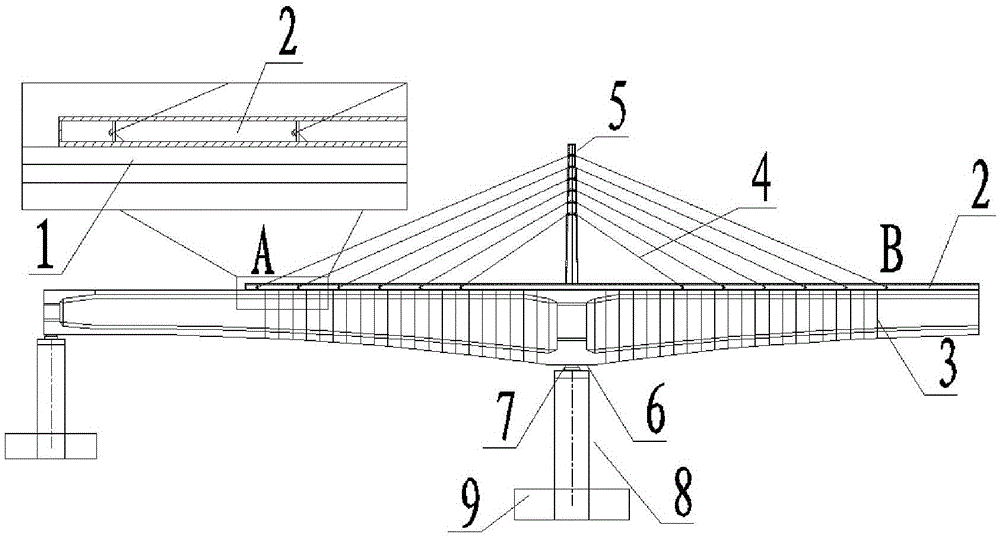

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described;

[0044] Utilize a kind of cable-stayed bridge structure and construction method for strengthening PSC continuous box girder bridge of above-mentioned design, concrete steps are as follows:

[0045] Step 1: Consult the data and get the bridge structure and disease status through actual measurement, survey and get the bearing capacity of the pre-reinforced bridge, which is used to get the stress of the bridge tower, cable, combined steel, and connecting device, and then determine the components The required number, size, steel grade and specific layout.

[0046] Step 2: Determine the cable tension sequence and each tension force based on the stress conditions obtained in step 1 and the structural form of bridge towers, cables, and combined steel sections.

[0047] Step 3: According to the steps, the mechanical operation capacity of the construction sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com