Special light bridge erecting machine for hollow slab

A hollow slab and bridge erecting machine technology, which is applied in the direction of erecting/assembling bridges, bridges, and bridge construction, etc., can solve the problems of overall bulkiness, high cost, inconvenient disassembly and assembly of bridge erecting machines, and achieves simple structure and convenient disassembly and assembly. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation, structure, features and functions of the light bridge erecting machine for hollow slabs according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

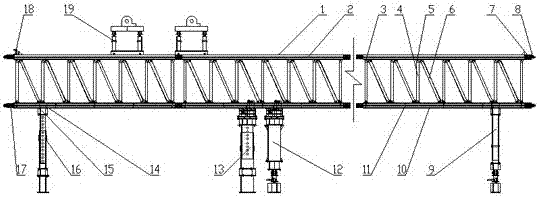

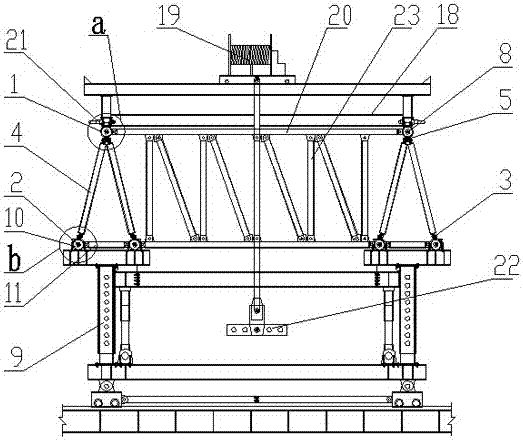

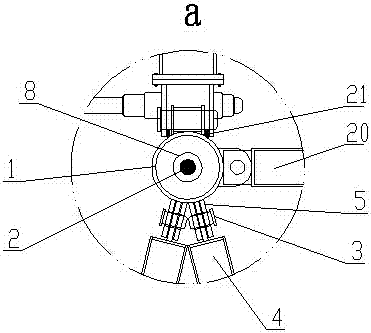

[0025] see Figure 1 to Figure 3 , the special light-duty bridge erecting machine for hollow slabs of the present invention, including "A" type main girder, front outrigger 9, middle outrigger 12, middle and auxiliary outrigger 13, rear outrigger 16, crane crane 19, "A" There are front outriggers 9, middle outriggers 12, middle and auxiliary outriggers 13, and rear outriggers 16 connected in sequence under the main girder, wherein: the upper chord 1 and the lower chord 10 of the "A" main girder are connected with a web A4 and the web B6, the lower chord beam 11 is installed between the lower chord 10, the upper chord 1 and the lower chord 10 are equipped with longitudinal prestressed steel bars 2, and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com