Method for detecting alignment between device graph on front face of wafer and back hole on back face

A detection method and wafer technology, applied in the field of semiconductors, can solve problems such as weak penetration of infrared light on metals, blocking of deformed parts, and difficulty in detecting alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

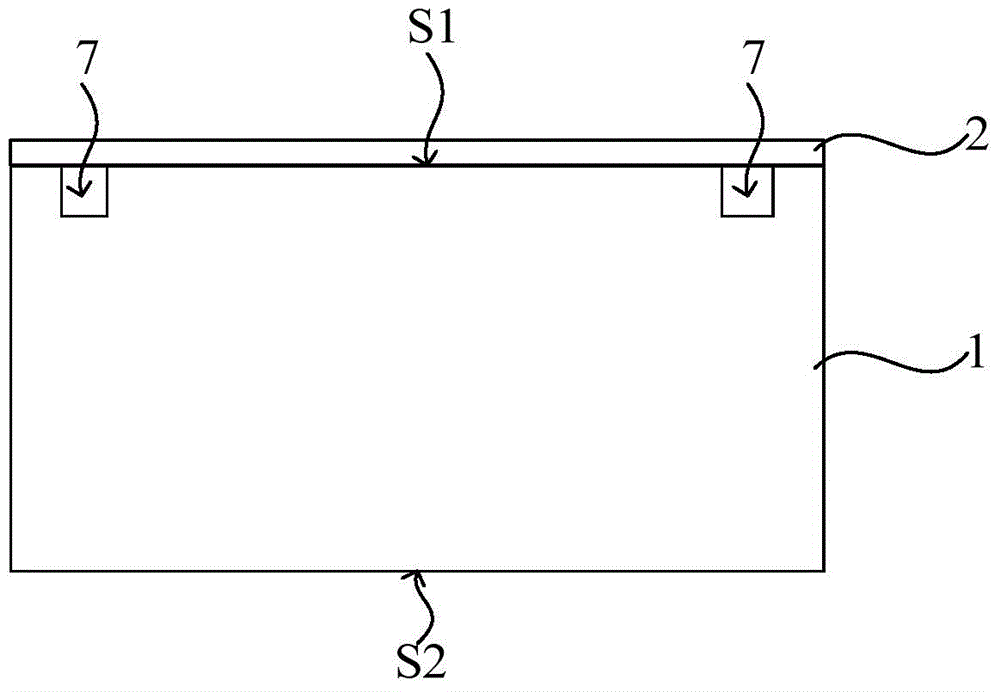

[0062] refer to Figure 5 , a wafer 100 is provided, the wafer has a front side S1 and a back side S2, and the front side S1 and the back side S2 are parallel to each other.

[0063] In a specific embodiment, an alignment mark (not shown in the figure) may be formed on the front surface S1 of the wafer 100 , and the alignment mark plays an alignment role in the subsequent photolithography process for defining the position of the device pattern.

[0064] In a specific embodiment, the wafer 100 may be a silicon wafer, a germanium wafer, or a silicon-on-insulator wafer, etc.; or the material of the wafer 100 may also include other materials, such as Group III-V compounds such as gallium arsenide. Those skilled in the art can select wafers as required, so the types of wafers should not limit the protection scope of the present invention.

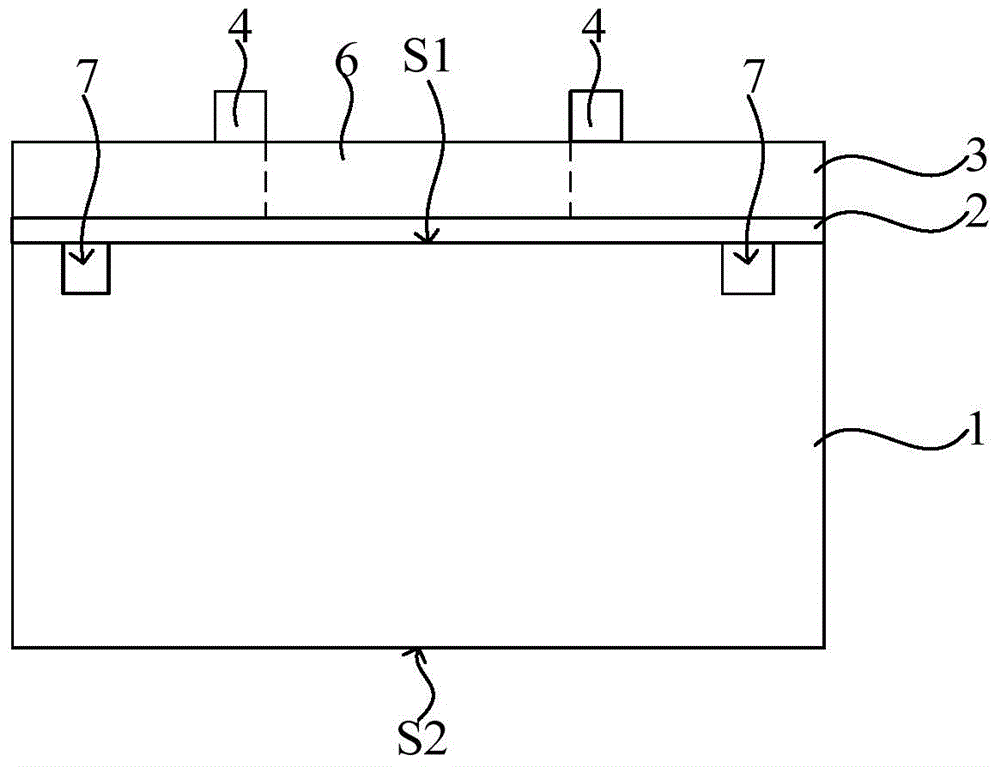

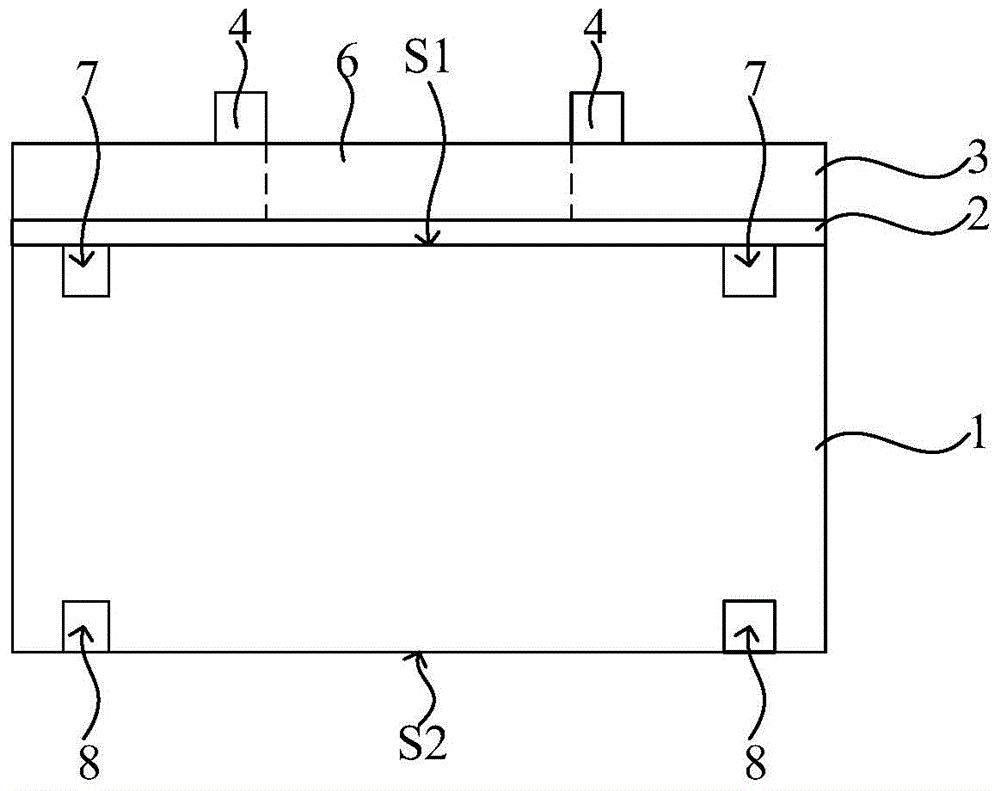

[0065] refer to Image 6 , an insulating layer 101 is formed on the front surface S1 of the wafer 100 , and the insulating layer 101 plays an...

no. 2 example

[0103] In this embodiment, refer to Figure 13 , Figure 14 , Figure 14 to correspond to Figure 13 top view, Figure 13 to correspond to Figure 14 A schematic diagram of the cross-sectional structure in the direction of BB, the detection mark 302 includes two sets of scale lines opposite to each other in a cross, namely a first set of scale lines 311 and a second set of scale lines 312 . The first set of tick marks 311 includes a plurality of first tick marks 321 spaced from each other on a straight line of the cross, and the second set of tick marks 312 includes a plurality of second tick marks separated from each other on another straight line of the cross. 322;

[0104] The intersection of the cross is defined to be within the boundary of the lower surface of the device pattern, and the boundary of the lower surface of the device pattern has two first intersections on the first set of scale lines 311 and two second intersections on the second set of scale lines 312 ...

no. 3 example

[0121] refer to Figure 18 , Figure 18In a plan view, detection marks 502 are formed on the insulating layer 501 . The detection mark 502 includes a crossed first coordinate axis 511 and a second coordinate axis 512, and the intersection of the first coordinate axis 511 and the second coordinate axis 512 is defined in the lower surface of the device pattern to be formed;

[0122] A plurality of first tick marks 521 distributed at equal intervals are set on the first coordinate axis 511 , and a plurality of second tick marks 522 distributed at equal intervals are set on the second coordinate axis 512 . The predefined first alignment position is the first coordinate of the two first intersections between the lower surface boundary of the subsequent device pattern and the first coordinate axis 511 , and the second coordinate of the two second intersections between the lower surface boundary of the device pattern and the second coordinate axis 512 . coordinate.

[0123] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com