On-site shale gas desorption analyzer

A desorption and shale gas technology, applied to the analysis of materials, instruments, etc., can solve the problems of large overall instrument volume, time-consuming and labor-intensive, human errors, etc., and achieve the effects of difficult transportation, reduced instrument volume, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

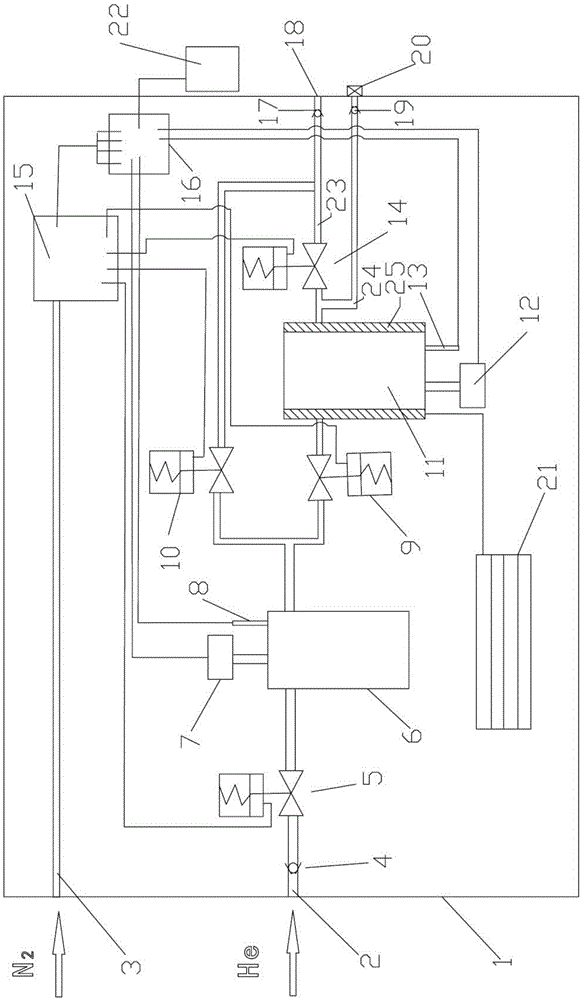

[0033] like figure 1 As shown, the shale gas on-site desorption analyzer of the present embodiment includes a desorption tank 11, and also includes a reference tank 6 and a thermostat 1, and the thermostat 1 is provided with a desorption tank 11, a reference tank 6, a first Pneumatic solenoid valve 5, the second pneumatic solenoid valve 9, the third pneumatic solenoid valve 10, the fourth pneumatic solenoid valve 14 and a temperature controller 21; Pneumatic solenoid valve 14 links to each other, the other end of the 4th pneumatic solenoid valve links to each other with exhaust pipe 23, and exhaust pipe passes through the exhaust hole 18 on the constant temperature box, is also connected on the pipeline between desorption tank and the 4th pneumatic solenoid valve Gas sampling pipe 24 is arranged, and this gas sampling pipe links to each other with the portable gas sampling interface 20 on the wall of the incubator, and check valve 17, 19 is all also provided with on exhaust pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com