Bearing structure for online ultrasonic method measurement of concentration of fluid

A load-bearing structure, ultrasonic technology, applied in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., to achieve superior linearity, reduce abrasion, and avoid wear effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

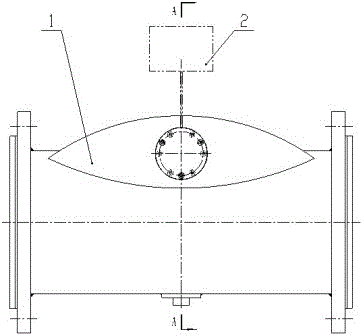

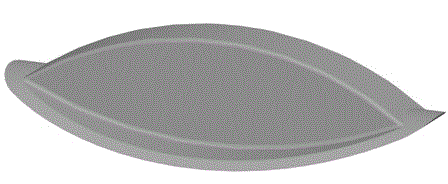

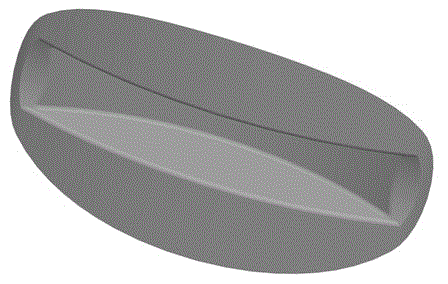

[0015] The structure of the present invention will be described in detail in conjunction with the accompanying drawings.

[0016] A load-bearing structure for measuring fluid concentration by online ultrasonic method, characterized in that: the main body 1 adopts gradual and smooth curve shape design, conforms to the fluid mechanics model structure, effectively reduces the frictional resistance between the fluid and the solid wall, so as to obtain The most stable measurement sample data ensures the representative data of the measurement sample, and also reduces the mechanism wear caused by obstruction. This structure also reduces the probability of turbulent flow, and weakens the influence of air bubbles on the sound wave attenuation and diffusion of the transducer when turbulent flow occurs; the precision casting structure reduces the roughness of the tube wall, and the inner wall is smooth and clean, reducing abrasion. At the streamline shape of the main body 1, a sending tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com