Bearing block for a handbrake lever

A technology for hand brake levers and support seats, which is applied in the direction of manual starting devices, control components, mechanical control devices, etc., and can solve problems such as tilting of the support seat, affecting the rigidity or stability of the side of the support seat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

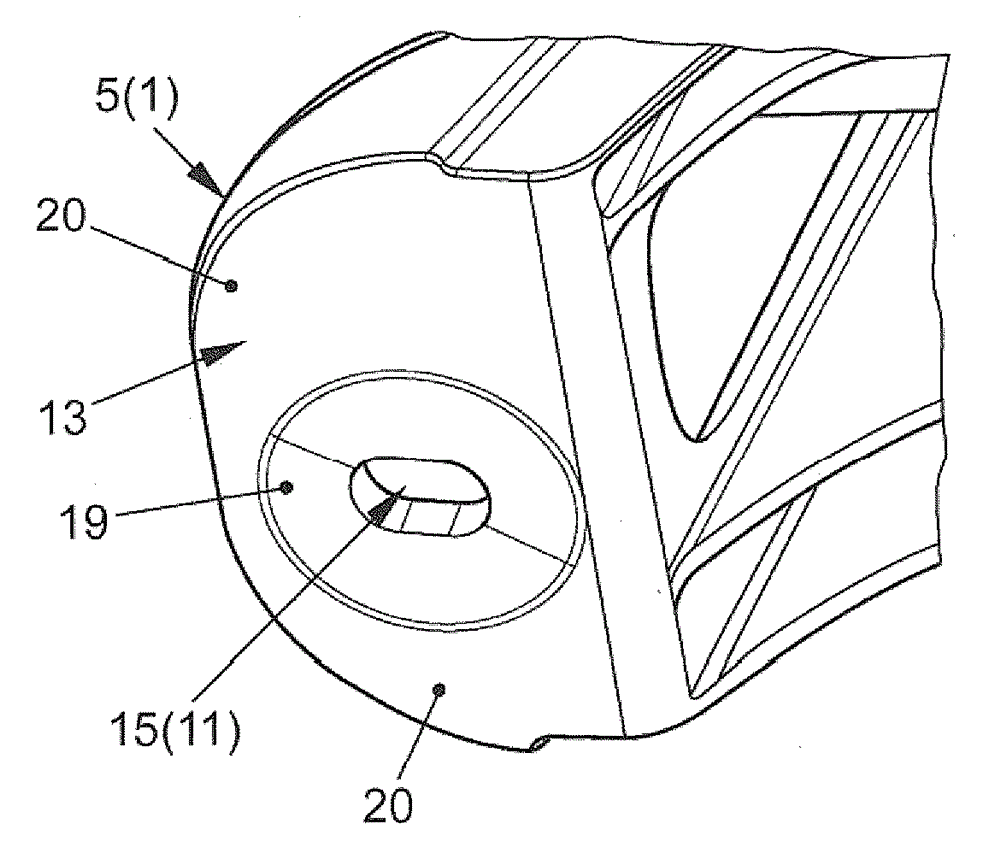

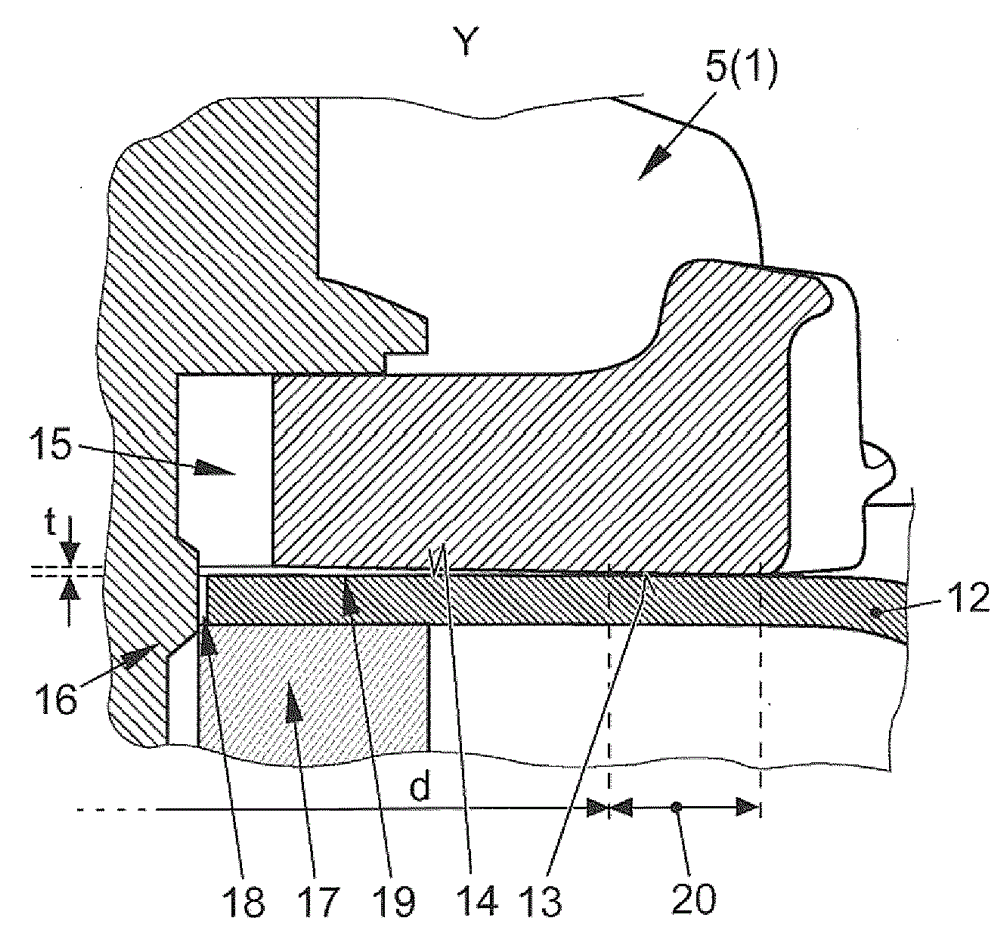

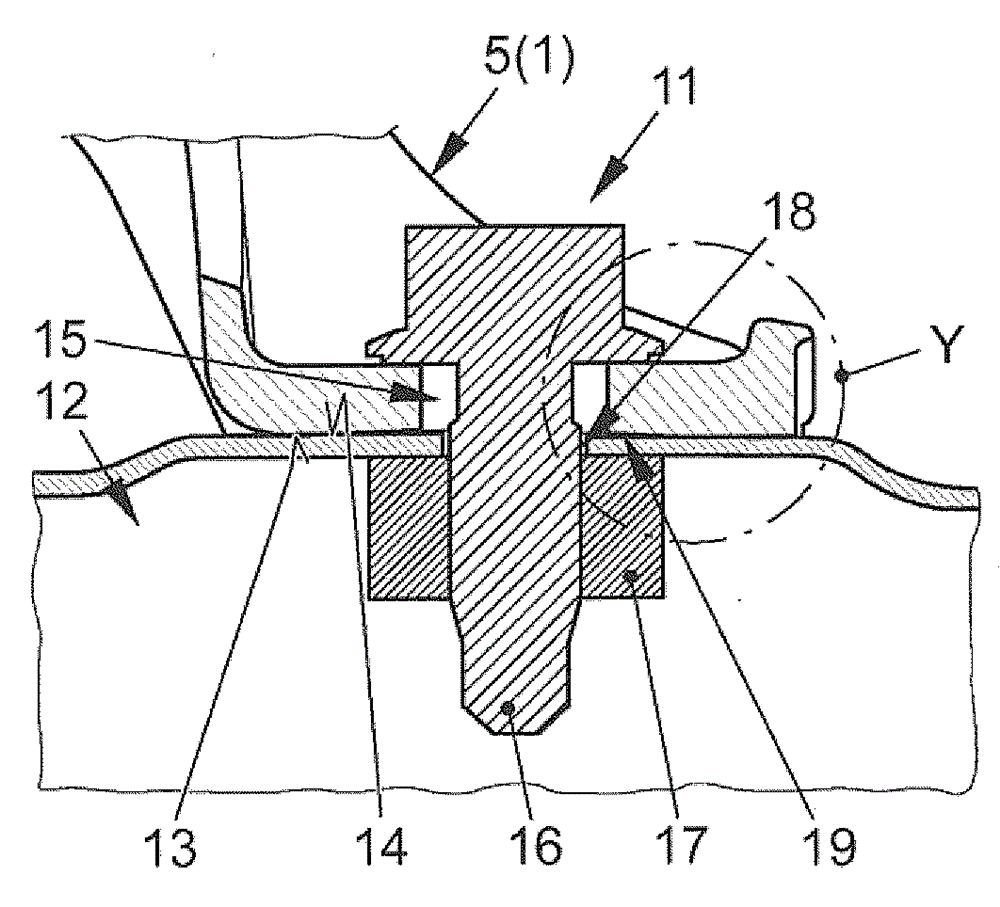

[0014] figure 1 First, a bearing base 1 for pivotably mounting a handbrake lever of a parking brake of a motor vehicle is shown, the function of which has basically been described in the prior art section in the introduction to the description. The bearing base 1 is advantageously produced in one piece according to the casting process and preferably is made of magnesium alloy as a lightweight construction material, which advantageously combines low weight with vibration and noise damping with sufficient strength. However, the invention is not limited to this casting material, but also includes other light metals suitable for casting, such as in particular aluminum or light metal alloys composed thereof. Also included are plastics or fiber-reinforced plastics of corresponding strength, which can be processed in particular by injection molding. Furthermore, the invention also includes a support base 1 (not shown in the figure), which is constructed, for example, from a steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com