Intraocular telescopic type artificial lens and production method thereof

A technology of intraocular lens and telescope, applied in the direction of intraocular lens, prosthesis, eye implant, etc., can solve the problem of high endothelial loss rate, achieve the effect of improving vision, product price and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

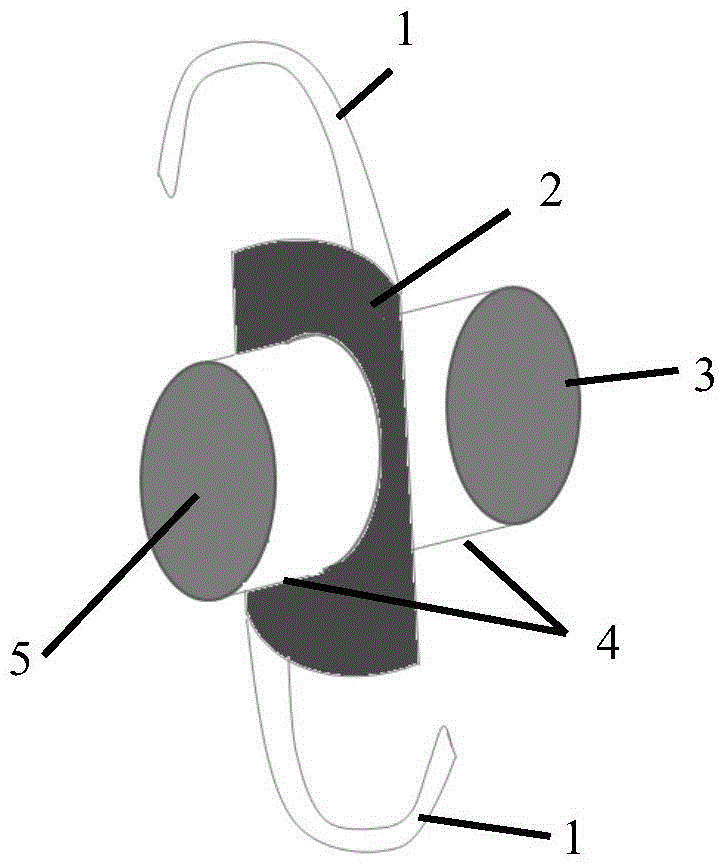

[0034] (1) Make the lens barrel and line it with an opaque sleeve: using hydrophobic acrylic material, a cylindrical tube with a height of 2mm and a diameter of 2mm is made by fine lathe, and lined with an opaque coating to prevent light scattering in the lens barrel. There are grooves near the mouth of the tube at the front and rear ends of the inner side for inlaying front and rear lenses; grooves are set at 0.5mm from the front end on the outer side for inlaying a brown light-shielding ring-double loop integrated structure.

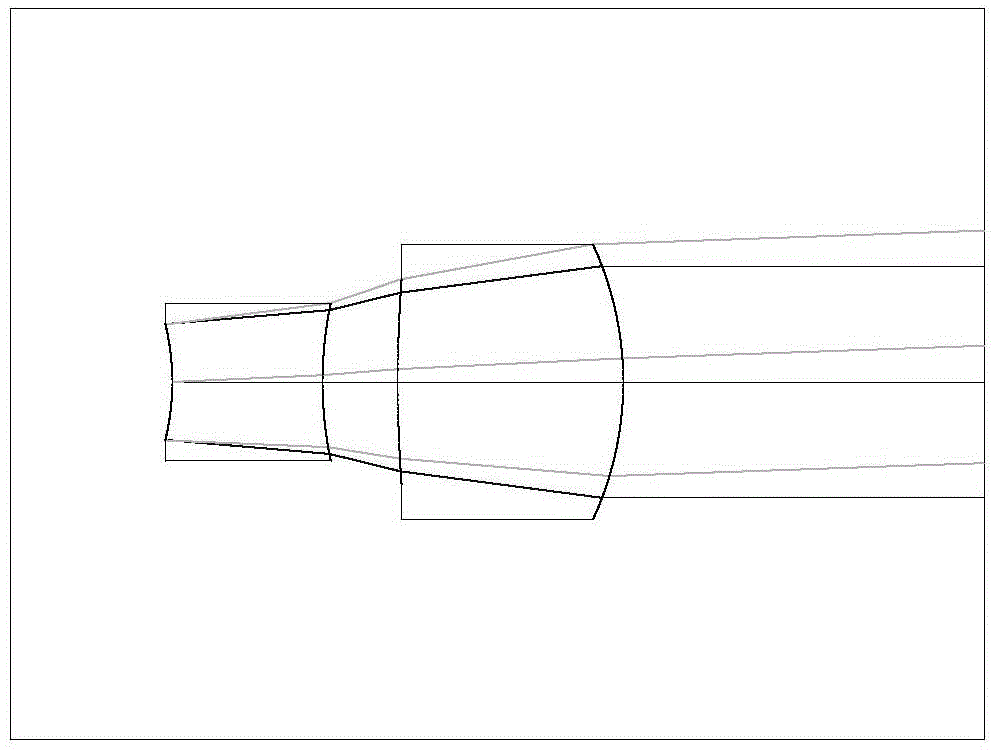

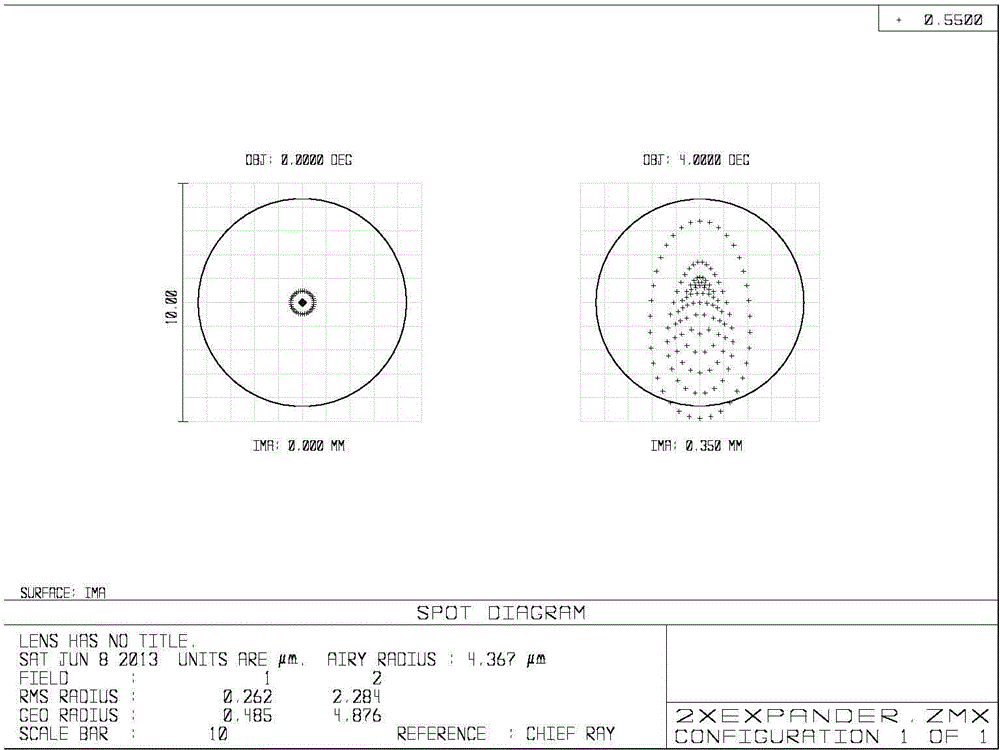

[0035] (2) Making optical lenses: The front and rear lenses are made of hydrophobic acrylic material, the front mirror is a negative lens, the radius of curvature of the front surface is -1.628mm, the radius of curvature of the rear surface is 2.584mm, and the thickness is 1mm; the rear mirror is a positive lens , the radius of curvature of the front surface is 9.066mm, the radius of curvature of the rear surface is -2.175mm, and the thickness is 1.5mm;...

Embodiment 2

[0040] (1) Make the lens barrel and line it with an opaque sleeve: using hydrophobic acrylic material, a cylindrical tube with a height of 2mm and a diameter of 2mm is made by fine lathe, and lined with an opaque coating to prevent light scattering in the lens barrel. There are grooves near the mouth of the tube at the front and rear ends of the inner side for inlaying front and rear lenses; grooves are set at 0.5mm from the front end on the outer side for inlaying a brown light-shielding ring-double loop integrated structure.

[0041] (2) Making optical lenses: The front and rear lenses are made of hydrophobic acrylic material, the front mirror is a negative lens, the radius of curvature of the front surface is -1.628mm, the radius of curvature of the rear surface is 2.584mm, and the thickness is 1mm; the rear mirror is a positive lens , the radius of curvature of the front surface is 9.066mm, the radius of curvature of the rear surface is -2.175mm, and the thickness is 1.5mm;...

Embodiment 3

[0046] (1) Make the lens barrel and line it with an opaque sleeve: using hydrophobic acrylic material, a cylindrical tube with a height of 2mm and a diameter of 2mm is made by fine lathe, and lined with an opaque coating to prevent light scattering in the lens barrel. There are grooves near the mouth of the tube at the front and rear ends of the inner side for inlaying front and rear lenses; grooves are set at 0.5mm from the front end on the outer side for inlaying a brown light-shielding ring-double loop integrated structure.

[0047] (2) Making optical lenses: The front and rear lenses are made of hydrophobic acrylic material, the front mirror is a negative lens, the radius of curvature of the front surface is -1.628mm, the radius of curvature of the rear surface is 2.584mm, and the thickness is 1mm; the rear mirror is a positive lens , the radius of curvature of the front surface is 9.066mm, the radius of curvature of the rear surface is -2.175mm, and the thickness is 1.5mm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com