Three-dimensional printing preparation method for orthoses

A technology of three-dimensional printing and orthotics, which is applied in the direction of medical science, etc., can solve the problems of complicated shape-taking and modification, complicated shape-taking process, long production time, etc., and achieves the effects of rapid production and forming, low price and small product deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

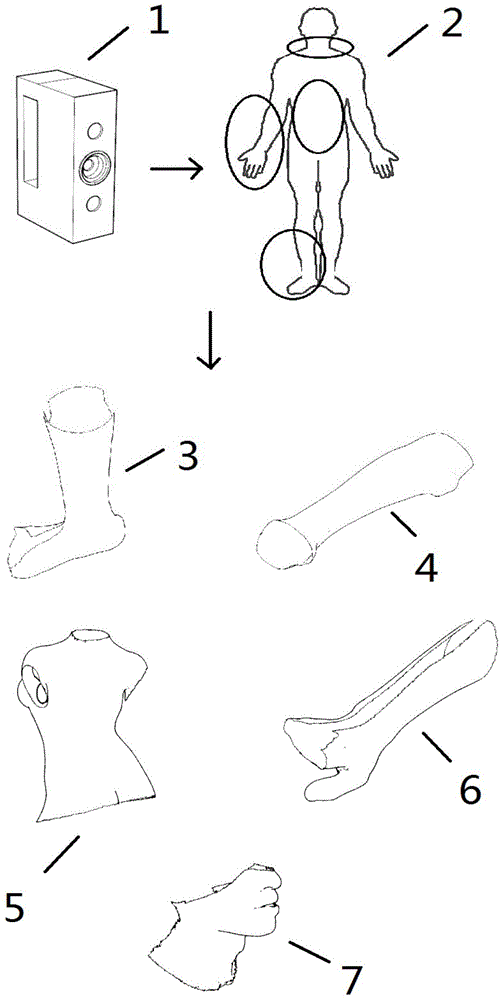

[0032] By operating the Sense hand-held body scanner 3D scanner (1) of 3D systems, the patient needs to be corrected, that is, the limb to be scanned (2) is scanned in 3D, and the 3D scan data of the patient's leg to be corrected (3) is obtained by scanning ,Such as figure 1 shown.

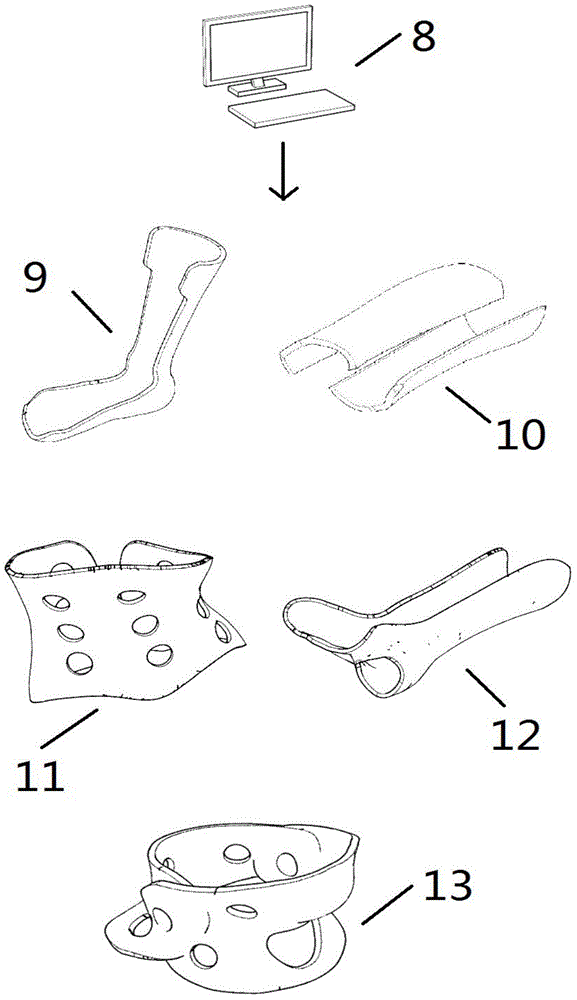

[0033] By using computer software (Magics software from Materialize Company) to process (8) the scanned body data, such as figure 2 As shown in Fig. 1, perform operations such as shape repair and shape correction on the limbs to be orthoticed to obtain a three-dimensional model of the ankle-foot orthosis (9).

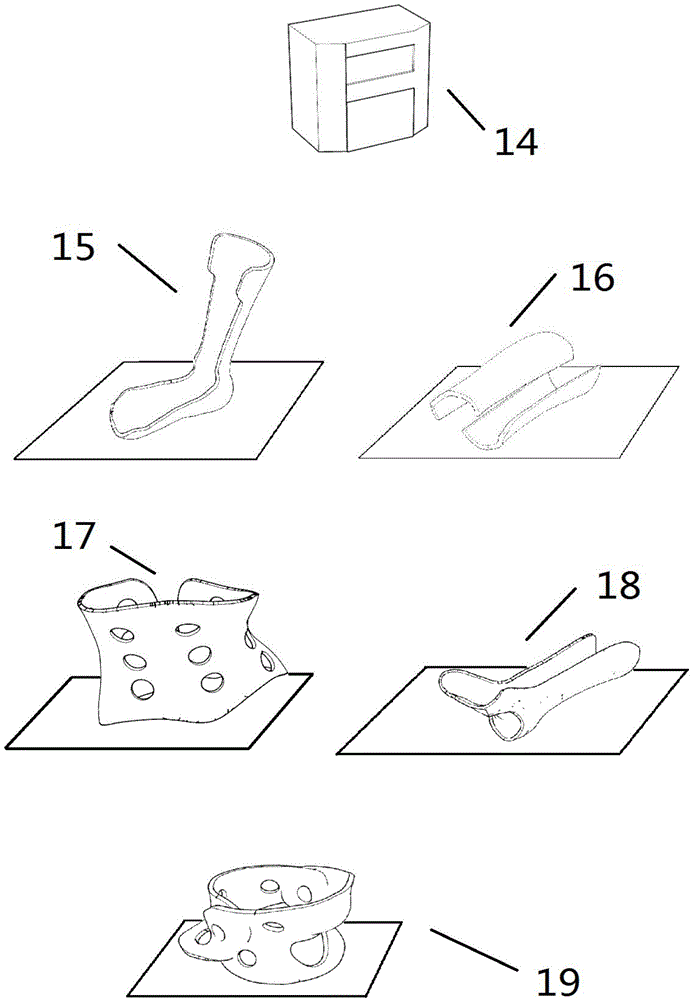

[0034] Input the three-dimensional model of the ankle-foot-orthosis into the three-dimensional printer, and produce (14) through the three-dimensional printer to obtain the ankle-foot-orthosis product (15), such as image 3 shown. Using the SLS laser sintering printer of EOS company, the nylon powder material is used for production. The surface of the heated raw material powder layer i...

Embodiment 2

[0036] By operating the Sense hand-held body scanner 3D scanner (1) of 3D systems company, a 3D scan is performed on the part of the patient to be orthopedic, that is, the limb to be scanned (2), and the 3D scanning data of the patient's arm (4) to be orthopedic is obtained from the scan. Such as figure 1 shown.

[0037] By using computer software (Magics software from Materialize Company) to process (8) the scanned body data, such as figure 2 As shown in Fig. 1, perform operations such as shape repair and shape correction on the limbs that need to be orthoticed, and obtain a three-dimensional model of the inner shell of the arm orthosis (10).

[0038] Input the 3D model of the inner shell of the arm orthosis into the 3D printer, and produce (14) through the 3D printer to obtain the inner shell (16) of the arm orthosis product, such as image 3 shown. The light-curing rapid prototyping printer of SHINING 3D is used for production with photosensitive resin materials. The s...

Embodiment 3

[0040] By operating the Sense hand-held body scanner 3D scanner (1) of 3D systems company, a 3D scan is performed on the patient’s body to be corrected (2), and the 3D scan data of the patient’s torso (5) to be corrected is obtained from the scan. Such as figure 1 shown.

[0041] By using computer software (Magics software from Materialize Company) to process (8) the scanned body data, such as figure 2 As shown in Fig. 1, perform operations such as shape repair and shape correction on the limbs to be corrected, and obtain a three-dimensional model of the inner shell of the lumbosacral orthosis (11).

[0042] Input the 3D model of the inner shell of the lumbosacral orthosis into the 3D printer, and produce (14) through the 3D printer to obtain the inner shell of the lumbosacral orthosis (17), such as image 3 shown. The light-curing rapid prototyping printer of SHINING 3D is used for production with photosensitive resin materials. The solidified block is formed by laser sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com