Tubular dissolved nozzle electroslag welding device of steel structural high-rise building construction

A high-rise building and electroslag welding technology is applied in the field of tubular melting nozzle electroslag welding devices in the construction of high-rise buildings with steel structures, and can solve the problems of poor production efficiency and low quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

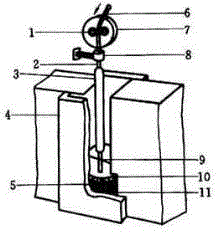

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] An electroslag welding device with a tubular melting nozzle for steel structure high-rise building construction, which consists of a feed roller (1), a tubular melting nozzle (2), a drug coating (3), a water-cooled copper block (4), and a slag shell on the surface of the weld ( 5), welding wire (6), motor (7), tubular nozzle holder (8), slag pool (9), molten metal (10) and weld seam (11), the electroslag welding is a For automatic welding, electroslag welding first generates an arc between the electrode and the arc striker, and uses its heat to melt the surrounding flux and turn it into liquid slag. When the liquid slag reaches a certain depth in the space between the weldment and the cooling slider (forming the slag pool (9)), the arc is extinguished, and the arc process is transformed into an electroslag process. When the welding current passes through the sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com