Spiral propulsion variable form snake-shaped robot

A snake-like robot and spiral propulsion technology, applied in manipulators, program-controlled manipulators, joints, etc., can solve the problems of low efficiency and high power consumption, and achieve the effects of prolonging working time, strong passability, and less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

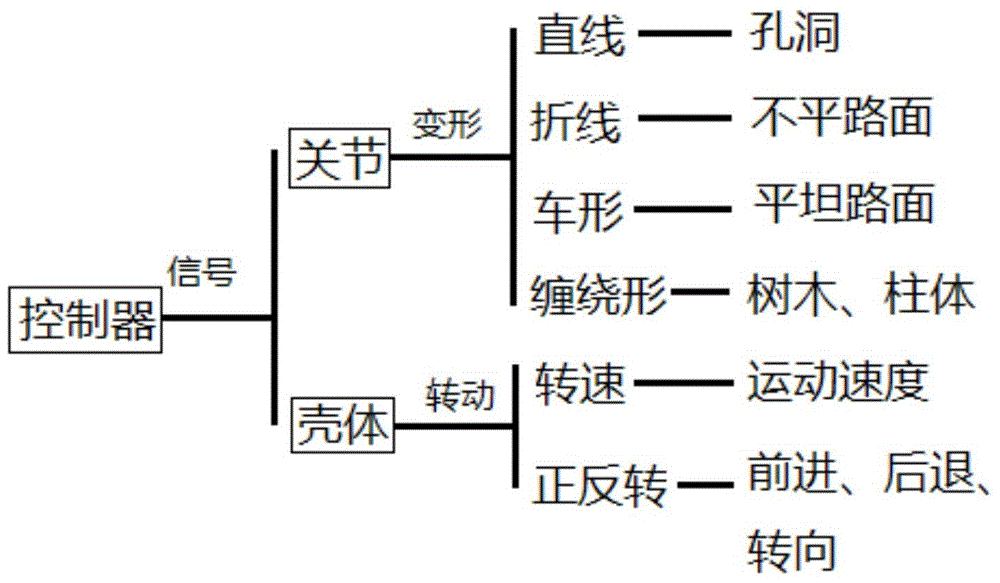

[0015] figure 1 The structure, function and control method of the snake-shaped robot are intuitively displayed. The controller sends out control signals to control the joints and the spiral shell to enter different postures and motion states, so that the entire snake-shaped robot can realize various shapes and motion modes, so as to move efficiently in different environments. figure 1 Four kinds of postures are listed for the snake-like robot to be generated by the control joints to adapt to four typical environments. In addition, through the appropriate transformation of postures and motions, it can achieve more functions such as climbing stairs and climbing obstacles.

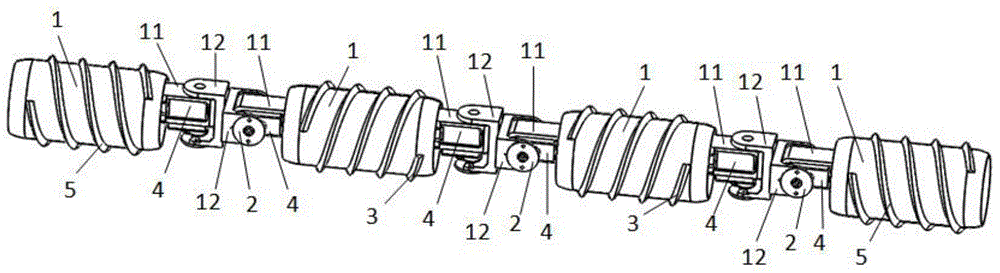

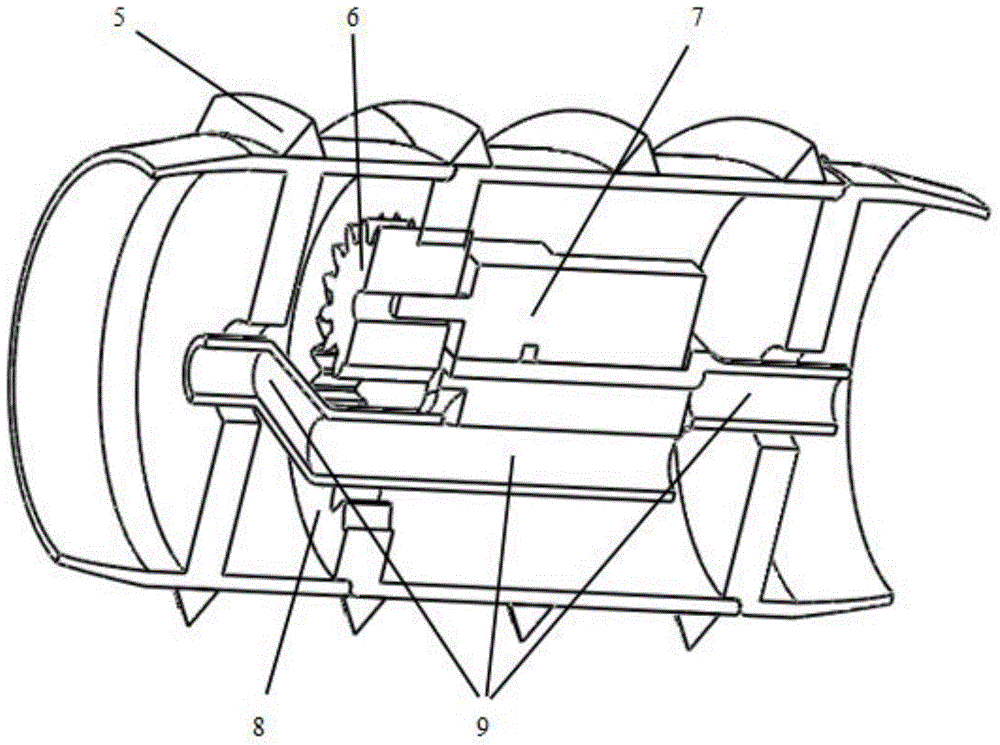

[0016] The key components of the whole snake-shaped robot are: a steering gear 4 is fixedly installed on the steering gear bracket 11, one end of the U-shaped connecting rod 12 is fixed with a steering gear disk 2, and the steering gear disk 2 is fixed on the rotating shaft of the steering gear 4, The other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com