Special-shaped wall pipe holder, socket forming mould and bell and spigot manufacturing equipment

A technology for socket forming and manufacturing equipment, applied in socket manufacturing equipment, socket forming molds and their bearing fields, can solve the problems of low degree of automation, imprecise size, low production efficiency, etc., and achieves ingenious structural design and convenience. The effect of demoulding and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] A best implementation is described below through a detailed introduction of its overall structure and performance.

[0064] The following takes the spiral wound pipe as an example to first introduce the characteristics of the pipe to be processed.

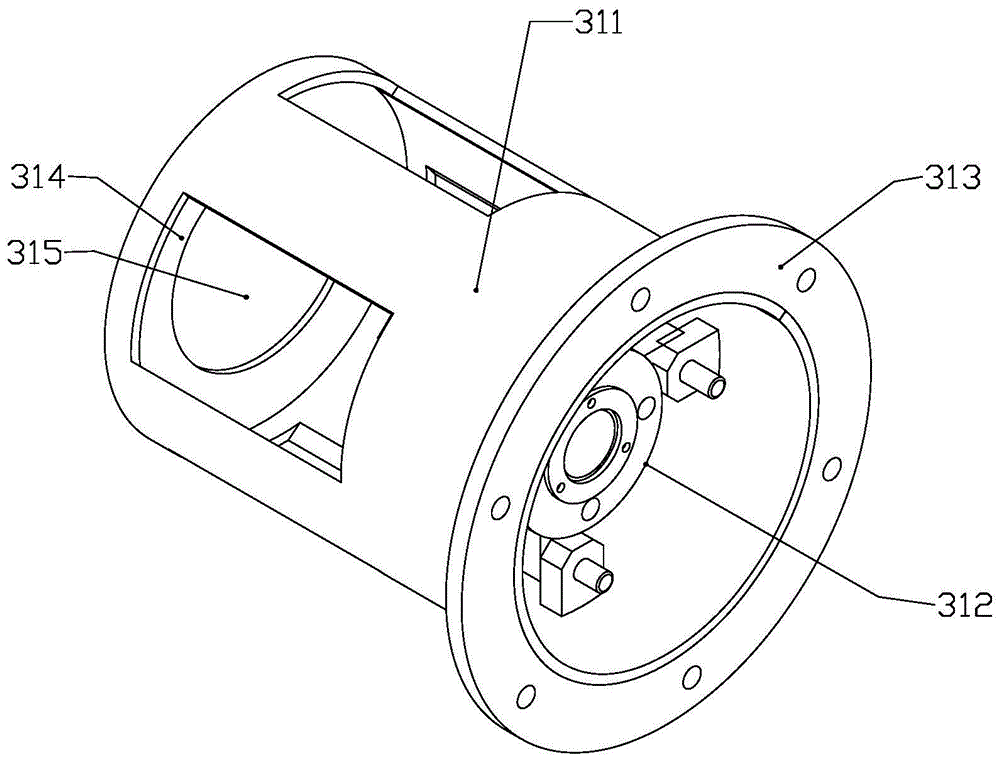

[0065] Such as Figure 27 As shown, a socket-type pipe includes a spirally wound pipe body 1. The spirally wound pipe is a composite pipe formed by adding two raw materials of PVC / PEL to steel strips or steel ribs, and is cut to form a pipe with a certain length. , this device deals with this port, and can form a structure that can be inserted and inserted. The two ends of the spirally wound pipe body are compounded with a socket 11 and a socket 12, such as Figure 28 , and the edges of the socket and the socket are superimposed on the helically wound pipe body and machined, such as Figure 29 , In this way, a occlusal effect will be formed at the lap joint to improve the connection strength between the two, and then a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com