Closed-loop system oxygenator and flow/concentration regulating closed-loop control system thereof

A closed-loop system, oxygen flow technology, applied in non-electrical variable control, control/regulation system, and simultaneous control of multiple variables, etc. High degree of intelligence, powerful atomization function, good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

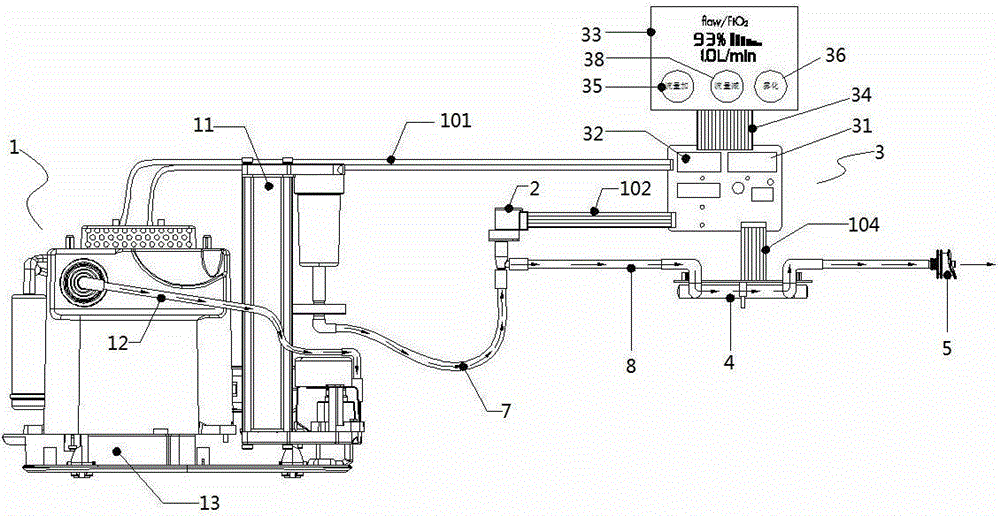

[0073] Such as figure 1 and 4 As shown in ~7, a closed-loop system oxygen generator includes an oxygen generator module assembly 1. The oxygen generator module assembly 1 includes a compressor 13, a main gas delivery pipe 12, and an oxygen generator molecular sieve assembly 11. One end of the main gas delivery pipe 12 is connected to the compressor 13 is connected, and the other end is connected with oxygen-generating molecular sieve assembly 11;

[0074] The output end of the oxygen-generating molecular sieve assembly 11 is connected with an electrically controlled flow valve 2 through a high-concentration oxygen pipe 7,

[0075] The electronically controlled flow valve 2 is electrically connected to the control module 3 through a wire 102;

[0076] The output end of the electronically controlled flow valve 2 is connected to the oxygen outlet nozzle 5 through the total flow output pipe 8; the oxygen flow / concentration sensor 4 is installed on the total flow output pipe 8 be...

Embodiment 2

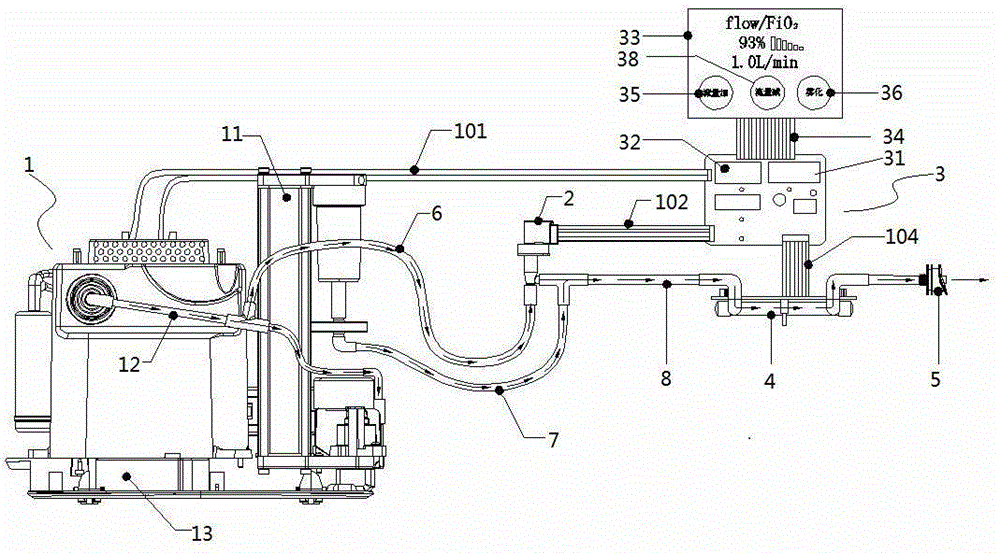

[0089] Such as figure 2 and 4 As shown in ~7, a closed-loop system oxygen generator includes an oxygen generator module assembly 1. The oxygen generator module assembly 1 includes a compressor 13, a main gas delivery pipe 12, and an oxygen generator molecular sieve assembly 11. One end of the main gas delivery pipe 12 is connected to the compressor 13 is connected, and the other end is connected with oxygen-generating molecular sieve assembly 11;

[0090] The output end of the oxygen-generating molecular sieve assembly 11 is connected to an electronically controlled flow valve 2 through a high-concentration oxygen pipe 7, and the electronically controlled flow valve 2 is electrically connected to the control module 3;

[0091] The output end of the electronically controlled flow valve 2 is connected to the oxygen outlet nozzle 5 through the total flow output pipe 8; the oxygen flow / concentration sensor 4 is installed on the total flow output pipe 8 between the electronically...

Embodiment 3

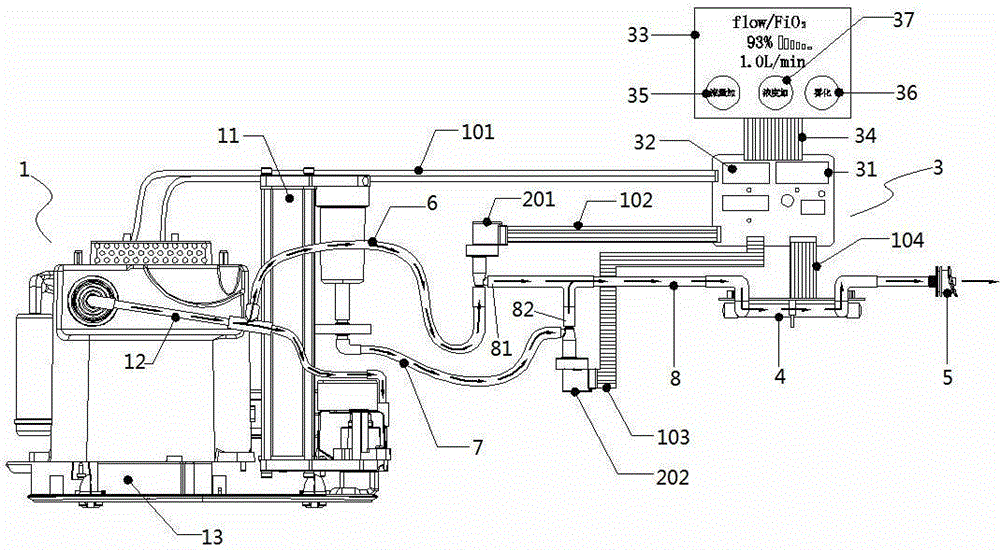

[0103] Such as Figure 3-7 As shown, a closed-loop system oxygen generator includes an oxygen generator module assembly 1, the oxygen generator module assembly 1 includes a compressor 13, a main gas delivery pipe 12, and an oxygen generator molecular sieve assembly 11, and one end of the main gas delivery pipe 12 is connected to the compressor 13 , the other end is connected to the oxygen-generating molecular sieve assembly 11;

[0104] It also includes two electronically controlled flow valves, which are divided into electronically controlled flow valve A201 and electronically controlled flow valve B202, both of which are the electronically controlled flow valves described in the above-mentioned embodiment 1, and the stepper motor 21 of the electronically controlled flow valve A201 passes through The wire 102 is electrically connected to the control module 3; the stepper motor 21 of the electronically controlled flow valve B202 is electrically connected to the control module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com