A kind of sludge treatment method of urban sewage treatment plant

A technology for urban sewage and treatment methods, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. characteristics, improve the economic efficiency of enterprises, and reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

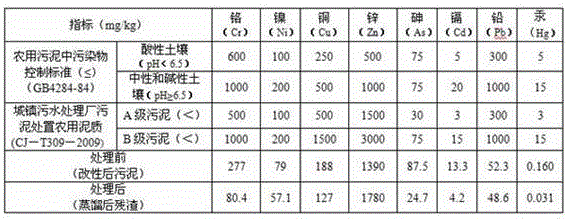

[0022] The treatment method of a kind of urban sewage treatment plant sludge of the embodiment 1 of the present invention is to satisfy the sludge produced by the exposed rivers and lakes in the cities and towns as a premise, and it is to treat the sludge according to dehydration modification and heavy metal treatment. The process steps are processed in a harmless manner, and the treated sludge meets the national pollutant control standards for agricultural sludge.

[0023] Its described dehydration modification step is:

[0024] ①Activation modifier: Weigh the amount of powder modifier used at one time according to the ratio of 0.05% of the weight of the sludge in a single treatment, and then weigh it according to the ratio of powder modifier usage to water ratio of 1:1.1 Take tap water and put it in a container and stir it evenly with the powdered modifier, and let it stand for 18 hours;

[0025] ② Dilute the modifier: add tap water with a weight ratio of 1:15 to the liquid...

Embodiment 2

[0032] A treatment method for urban sewage treatment plant sludge applicable to the condition of external air temperature T>20°C in Example 2 of the present invention is to carry out harmless treatment of urban sewage treatment plant sludge according to the process steps of dehydration modification and heavy metal treatment. Chemical processing, the processed sludge is distilled to extract mixed crude oil, and ammonium carbonate is extracted. The treated sludge meets the pollutant control standards in agricultural sludge.

[0033] Its described dehydration modification step is:

[0034] ①Activation modifier: Weigh the amount of powdered modifier used at one time according to the ratio of 0.08% of the weight of the sludge in a single treatment, and then weigh it according to the ratio of the amount of powdered modifier used to water as 1:1.3 Take tap water and put it in the container and stir it evenly with the powder modifier, and let it stand for 24 hours;

[0035] ② Dilute ...

Embodiment 3

[0044] The third embodiment of the present invention is applicable to the treatment method of urban sewage treatment plant sludge under the condition of external air temperature T<20°C, which is to make the urban sewage treatment plant sludge harmless according to the process steps of dehydration modification and heavy metal treatment Processing and treatment, the treated sludge is distilled to extract mixed crude oil and ammonium carbonate. The treated sludge meets the pollutant control standards in agricultural sludge.

[0045] Its described dehydration modification step is:

[0046] ① Activator: Weigh the amount of powdered modifier used at one time according to the ratio of 0.1% of the weight of the sludge in a single treatment, and then weigh it according to the ratio of the amount of powdered modifier used to water as 1:1.2 Tap water and put it in the container and stir it evenly with the powder modifier, and let it stand for 20 hours;

[0047] ② Dilute the modifier: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com