Unbonded prestressed tendon controllable segmented anchorage device and its assembly method and application

A prestressed tendon, controllable technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems such as segmentation problems that have not been well solved, and achieve convenient and fast construction, simple construction, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

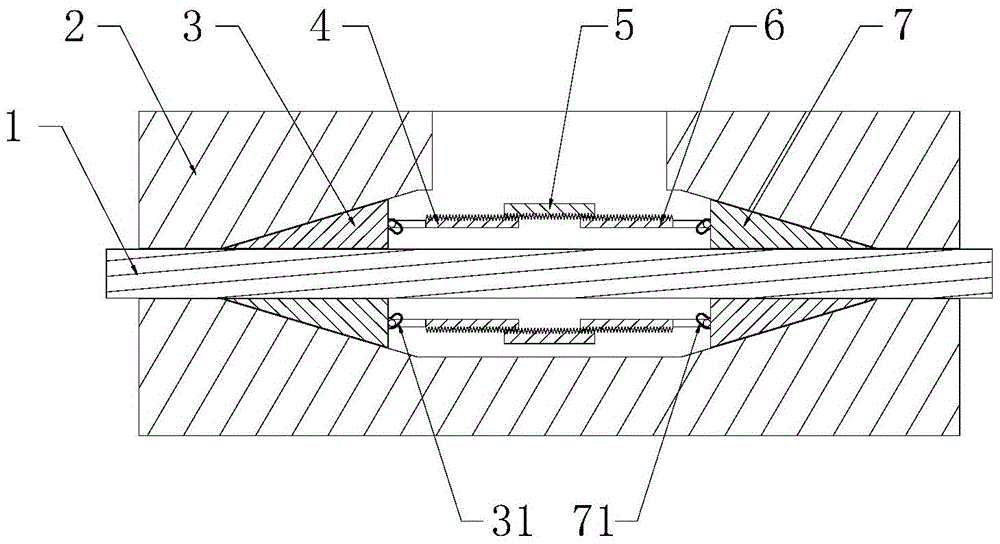

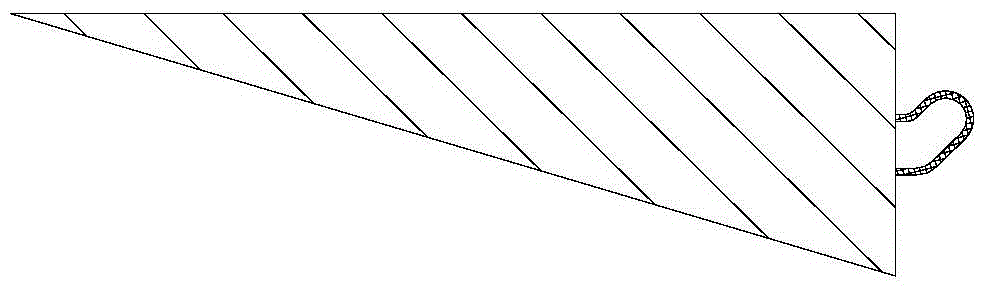

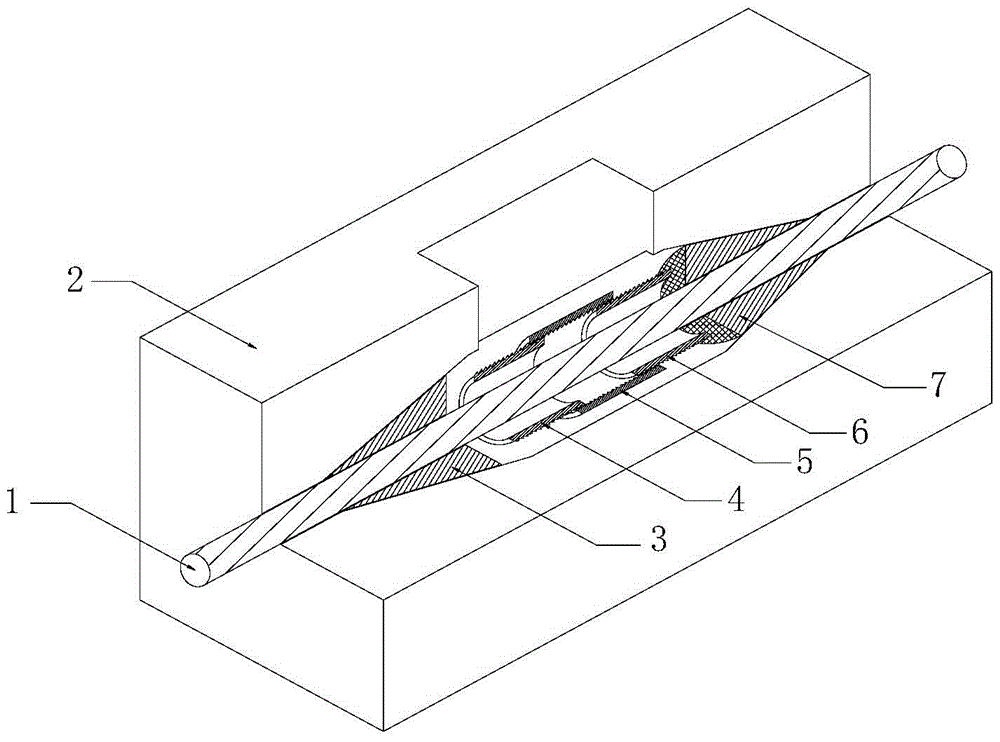

[0053] In the two-span continuous prestressed beam, install the controllable anchor segmental device in the node core area on the center column (see Figure 4 ), turn the outer threaded casing to make it in a non-working state, after passing through the prestressed tendons, pour concrete for the beam, and after the double-ended prestressed and anchored, reversely turn the outer threaded casing to make the controllable anchor segmented device in working condition. Realize the segmentation purpose of its two-span prestressed beam.

Embodiment 2

[0055] In the three-span continuous prestressed beam, one piece of the controllable anchor segment device is installed in the node core area on the center column (see Figure 5 ), turn the outer threaded casing to make it in a non-working state, after passing through the prestressed tendons, pouring beam concrete, 1) after tensioning the prestressed left end and anchoring, reversely turn the outer threaded casing to separate the controllable anchor When the section device is in working condition, the prestressed right end is stretched and anchored to achieve the purpose of segmenting the three-span prestressed beam. 2) After the left end and right end are prestressed and anchored, the externally threaded casing is reversely turned to put the controllable anchor segment device in working condition, realizing the segmental purpose of the three-span prestressed beam.

Embodiment 3

[0057] In the three-span continuous prestressed beam, two controllable anchorage segmental devices are respectively installed in the node core areas on the left and right central columns (see Image 6 ), turn the outer threaded casing to make both of them in the non-working state, after passing through the prestressed tendons, pour the beam concrete, 1) after tensioning the left end prestress and anchoring, reversely turn the outer threaded casing to make the left side controllable The sectional device of the controllable anchorage device is in the working state, and then the right end is prestressed and anchored, and the external threaded casing is reversely turned to make the controllable sectional device of the anchorage device in the working state to realize the sectionalization of the three-span prestressed beam. Purpose. 2) After the left end and right end are prestressed and anchored, the externally threaded casing is rotated in reverse to make the two controllable anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com