Gas spring device

A technology of gas springs and steel pipes, applied in the field of gas springs, can solve problems such as affecting processing procedures, reducing work efficiency, and poor compression resistance, and achieves the effects of improving compressive strength, simple structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

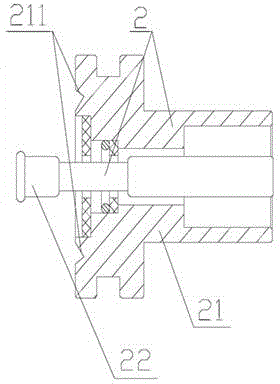

[0010] As shown in the figure, a gas spring device includes a steel pipe (1). One end of the steel pipe (1) is provided with a valve body assembly (2) and a piston assembly (3) from the inside to the outside, and a tail plug is provided at the port at the other end. There is also a partition piston inside the steel pipe (1), which is characterized in that: the valve body assembly (2) has a valve body (21), a valve needle (22) inserted into the valve body (21) and a gasket, Two V-shaped grooves (211) are formed on the end surface of the body (21), and the valve needle (22) is arranged between the two V-shaped grooves (211).

[0011] Preferably, the V-shaped groove (211) is stamped and formed. Further, the first fixing portion extends obliquely upward from the slope of the first body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com