Vehicle LED (light emitting diode) headlamp heat dissipation system and vehicle headlamp

A heat dissipation system and headlight technology, applied in the field of vehicles, can solve the problems of poor heat dissipation of headlights, etc., and achieve the effect of being free from human manipulation, efficient heat dissipation, and good luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

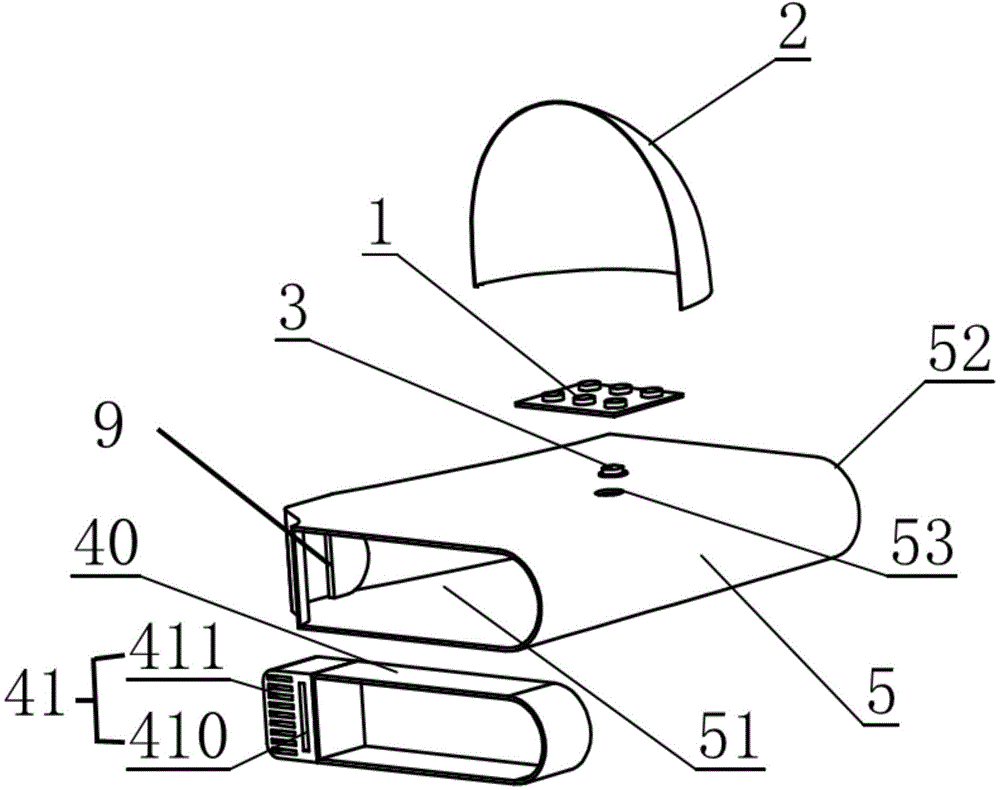

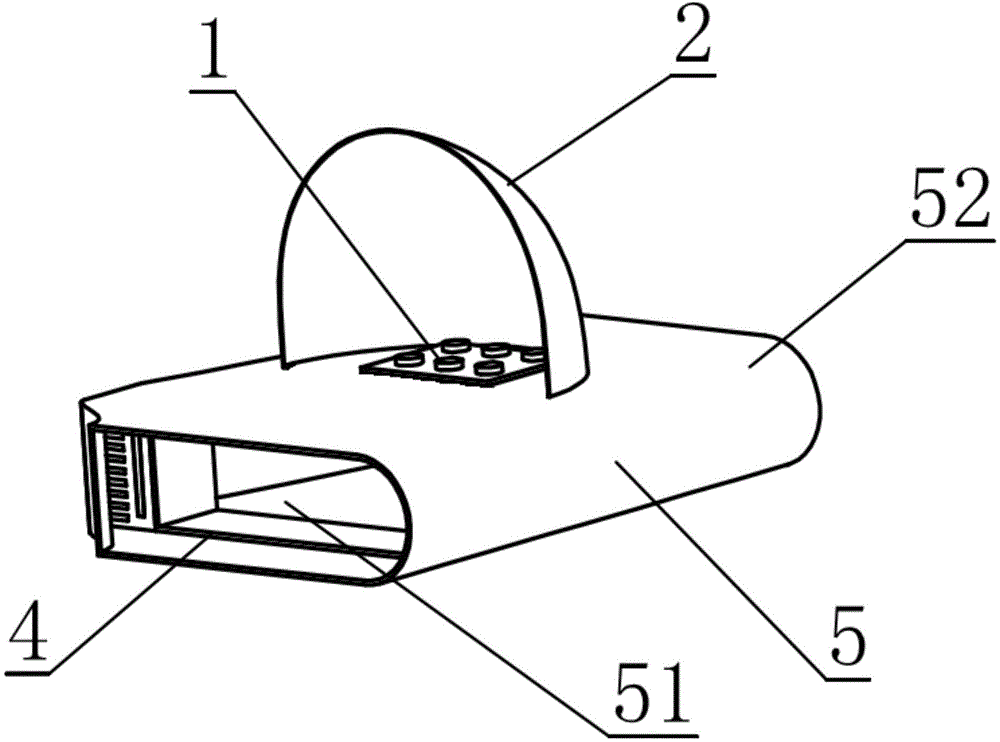

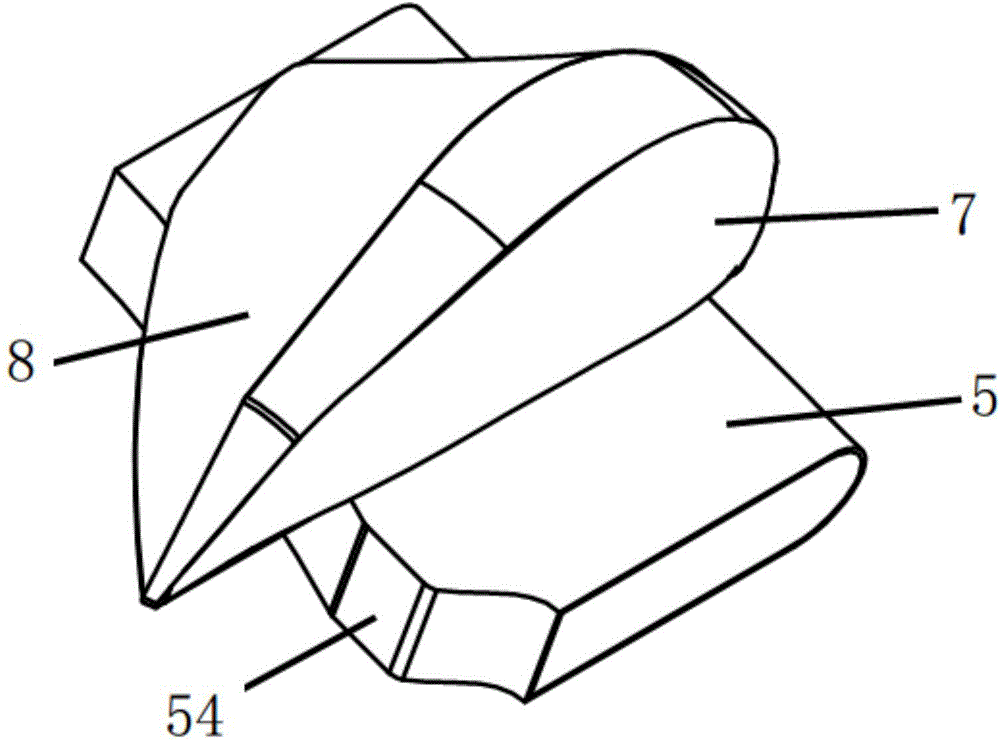

[0023] Examples, see figure 1 , figure 2 As shown, a vehicle LED headlight heat dissipation system of the present invention includes an LED light source module 1, and also includes a heat dissipation channel 5 and a bladeless fan 4, and the heat dissipation channel 5 adopts metal (such as aluminum alloy) with relatively high thermal conductivity. It is manufactured, and its interior is designed to be streamlined. It has an air inlet 51 toward the front of the vehicle and an air outlet 52 toward the rear of the vehicle; the LED light source module 1 is arranged on the outer wall of the upper wall of the heat dissipation channel 5 without leaves. The fan 4 is installed inside the heat dissipation channel 5 , and the air inlet 411 of the bladeless fan 4 corresponds to the air inlet 51 of the heat dissipation channel 5 , and the air outlet of the bladeless fan 4 corresponds to the air outlet 52 of the heat dissipation channel 5 . Specifically, the bladeless fan 4 is located at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com