Combined heat exchanger

A heat exchanger and liquid separator technology, applied in refrigeration components, evaporators/condensers, lighting and heating equipment, etc., can solve problems such as unfavorable energy conservation and emission reduction, environmental noise pollution, increased fan noise, etc. , The effect of reducing the resistance loss along the way and improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A combined heat exchanger of the present invention will be described in detail below with reference to the accompanying drawings.

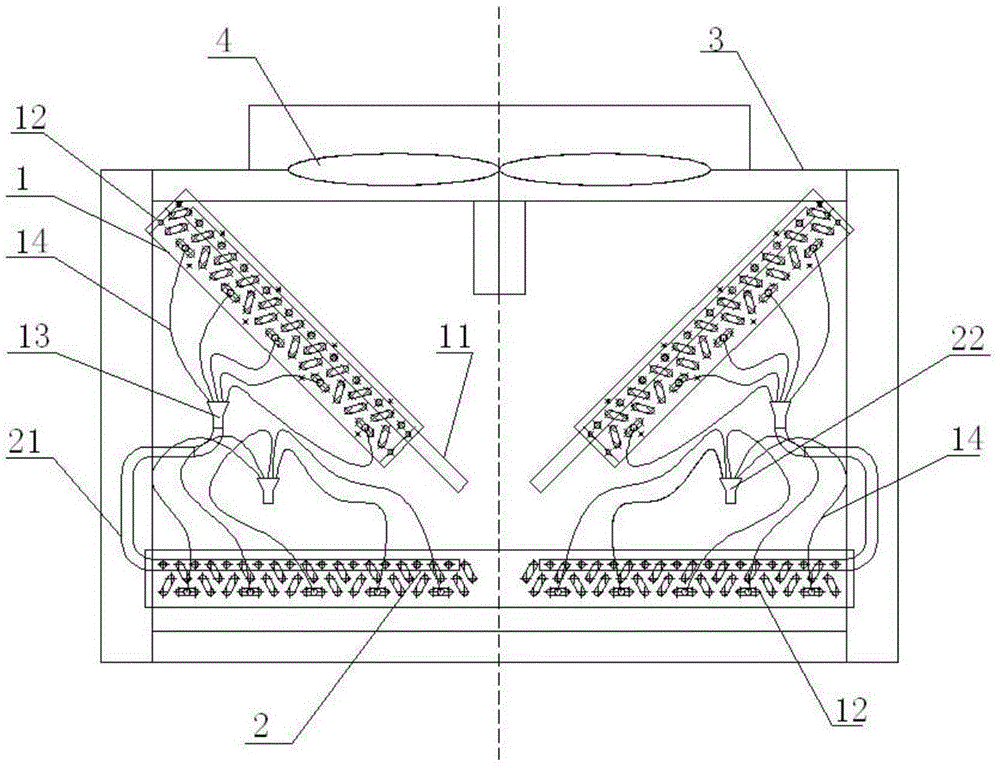

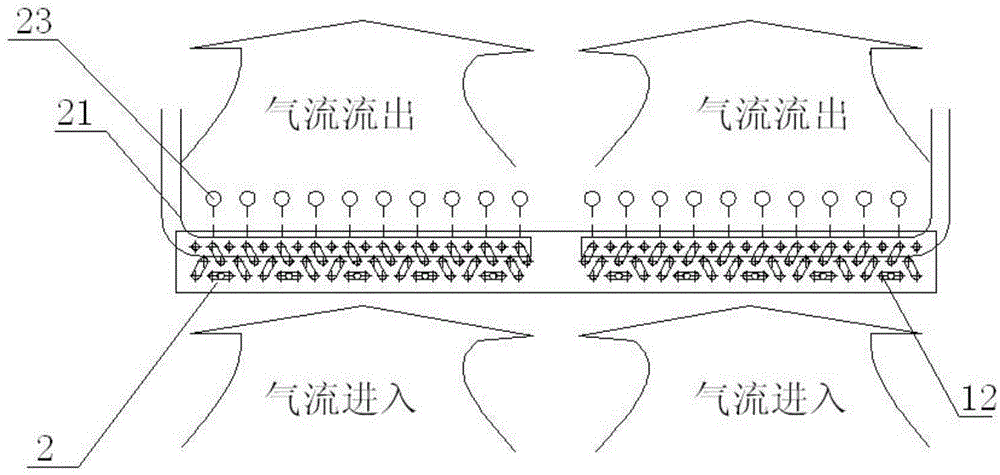

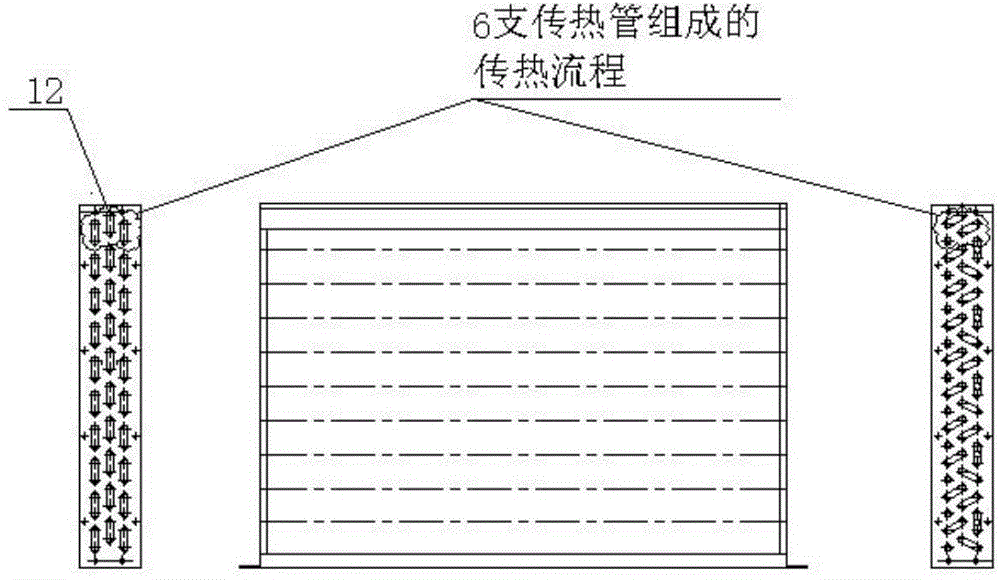

[0020] A combined heat exchanger includes an air-cooled heat exchanger 1 , a spray-cooled heat exchanger 2 , a shell 3 and a fan 4 . Such as figure 1 As shown, the air-cooled heat exchanger 1 and the spray-cooled heat exchanger 2 are located in the casing 3, and the casing 3 is a square box. The exchange area increases and the heat exchange efficiency increases. The spray cooling heat exchanger 2 is located directly below the V shape, and the spray cooling heat exchanger 2 is placed horizontally and horizontally. A primary side liquid separator 13 is provided below the two air-cooled heat exchangers 1 , and the primary side liquid separator 13 is connected to the spray cooling type heat exchanger 2 through a spray cooling type header 21 . The fan 4 is located at the upper end of the combined heat exchanger and installed on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com