Mechanical equipment maintenance field safety isolation method

A technology of mechanical equipment and safety isolation, applied in the field of safety isolation, can solve problems such as hidden safety hazards, uneasy minds of maintenance personnel, power outages of equipment, listing, delisting, inconvenient power transmission, etc., to reduce labor intensity, easy operation, and ensure The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

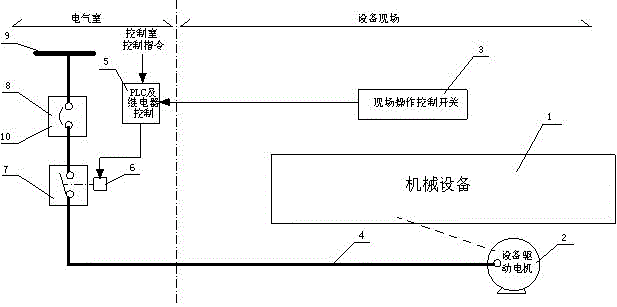

Method used

Image

Examples

Embodiment 1

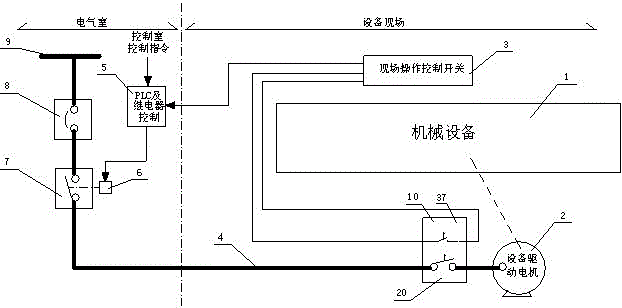

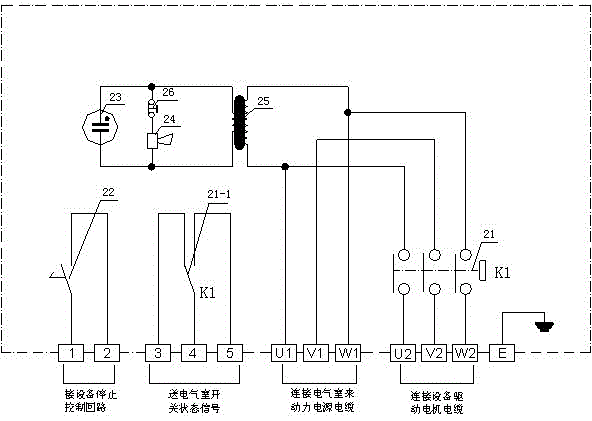

[0038] see figure 2 , image 3 , one On-site safety isolation device 20 for maintenance of mechanical equipment, including load isolation switch 21, equipment stop control switch 22, warning light 23, sound alarm device 24, alarm device power transformer 25, door opening threshold switch 26, explosion-proof isolation panel 36, isolation Box body 30 and box door 31.

[0039]The load isolating switch 21 is a load isolating switch without complex electrical protection devices such as quick disconnection and overload. It is only used for disconnecting and connecting the connection between the power line of the field equipment and the load. One end of the load isolating switch 21 is connected to the electrical room The other end of the fed-out power cable 4 is connected with the cable of the equipment drive motor 2 . When the load isolating switch 21 is in the closing position, the contact of the load isolating switch 21 is closed, and the power cable 4 fed from the electric r...

Embodiment 2

[0068]Another embodiment of the on-site safety isolating device for maintenance of mechanical equipment of the present invention is a form in which the operation of a load isolating switch is prohibited, which is in the form of an electronic door lock or an electronic alarm door lock. , equipment stop control switch 22, electronic alarm door lock 39, alarm device power transformer 25, isolation box 30 and box door 31. That is: from the circuit point of view: the electronic alarm door lock 39 replaces the warning light 23, the sound alarm device 24 and the door opening threshold switch 26 in embodiment 1, and from the isolation box, the electronic alarm door lock 39 replaces the door lock 32, no door opening threshold switch 26. see Figure 8 and Figure 9 ,details as follows:

[0069] One end of the load isolating switch 21 is connected to the power cable 4 fed out of the electric room, and the other end is connected to the cable of the equipment driving motor 2; Lead out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com