Calculating model for sintering and burdening

A batching calculation and model technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of many variables and unable to meet the composition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below, but it should be noted that the implementation of the present invention is not limited to the following embodiments.

[0053] The calculation model of sintering ingredients includes the following steps:

[0054] 1) The calculation model of sintering ingredients is a multi-constraint and multi-objective calculation model:

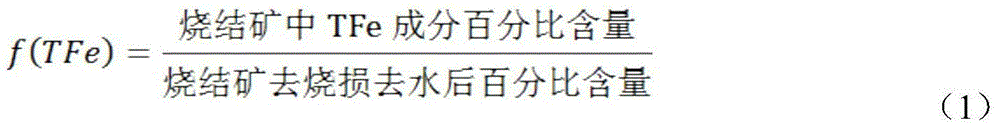

[0055] In the batching process, the iron grade Tfe, basicity R, and silica SiO of the sinter ore 2 , calcium oxide CaO, aluminum oxide Al 2 o 3 , Magnesium oxide MgO as a reference index, the calculation formula of target iron grade Tfe:

[0056]

[0057] TFe composition percentage content in sinter = ∑x i *A TFei (2)

[0058] Percentage content of sintered ore after burning loss and dehydration=∑x i *(100-A ilg )*(100-A iH2O ) (3)

[0059] In formula (2) and formula (3): x i Indicates the ratio of the i-th raw material; A TFei Indicates the percentage of TFe composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com