Improved nuclear fusion furnace

A technology of ring-shaped guide rails and shells, applied in the field of improved nuclear fusion furnaces, can solve problems such as difficult control and difficult effective use of nuclear fusion energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

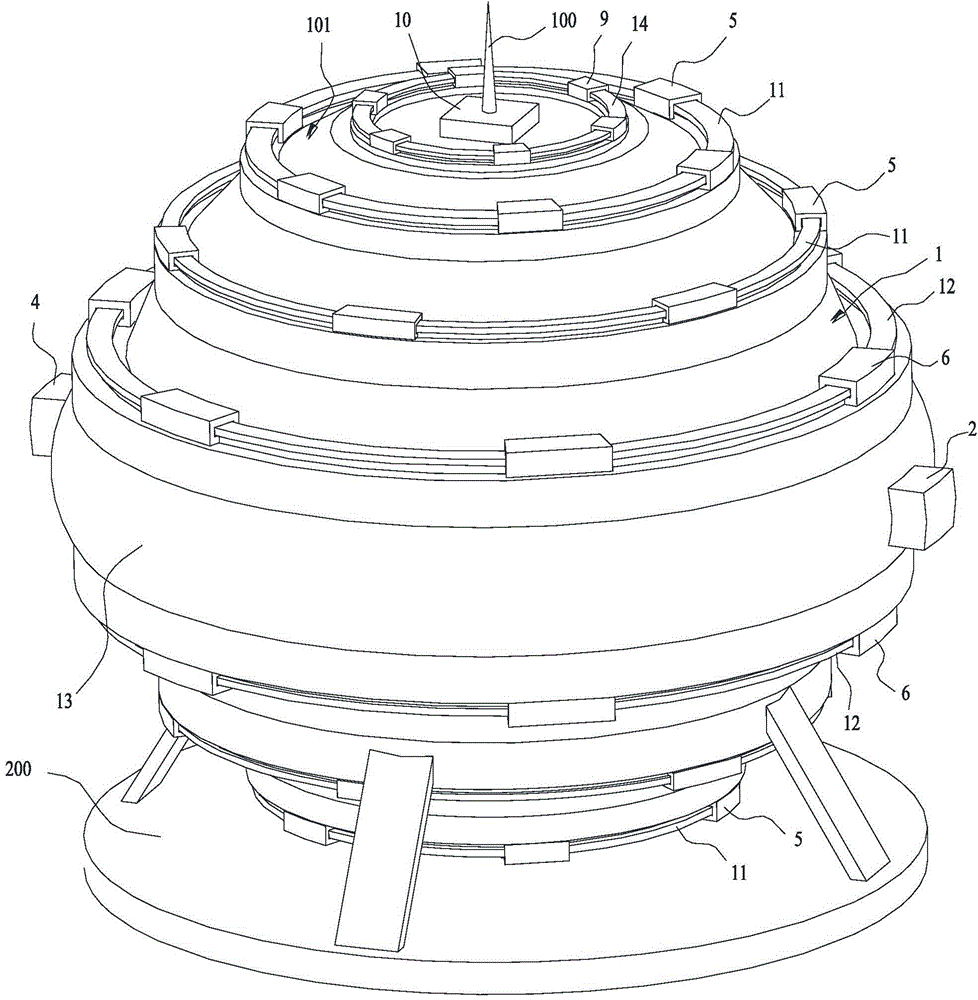

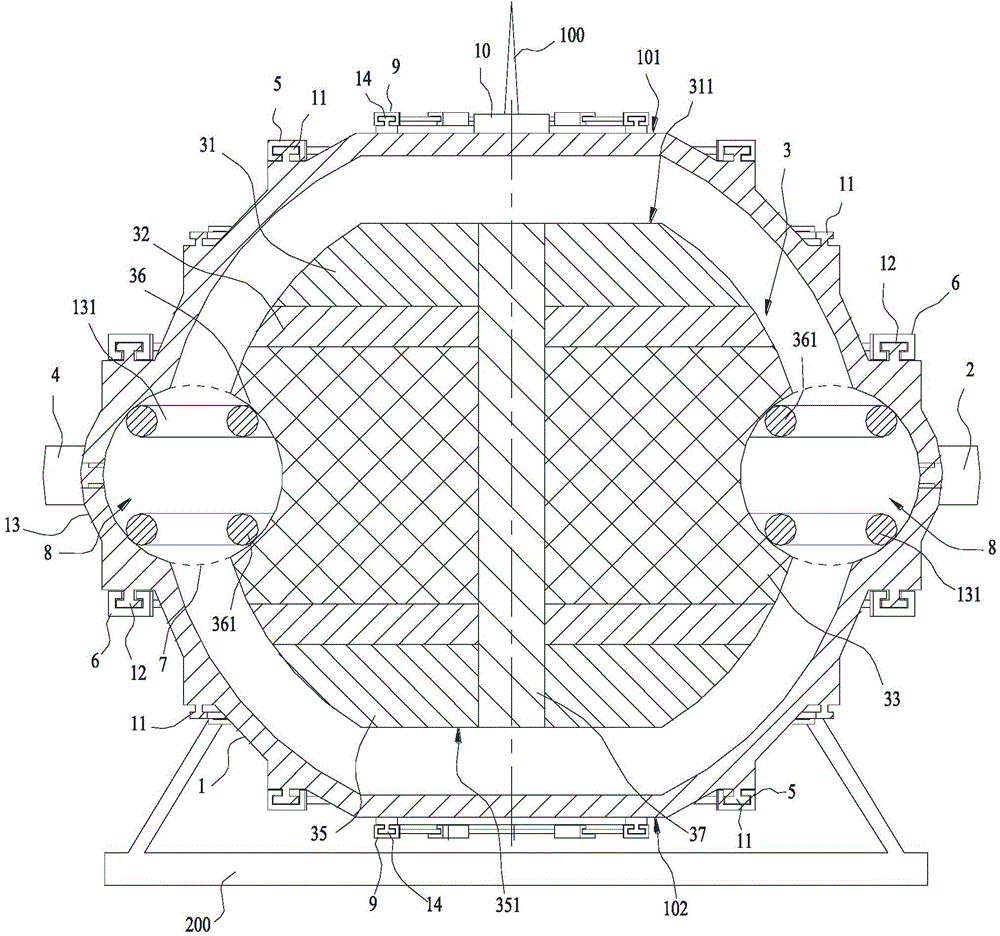

[0024] like Figure 1~2 The improved nuclear fusion furnace shown includes a magnetically conductive shell 1, an ignition device 2, a magnetic levitation ball 3, and a gas delivery device 4 for outputting a deuterium-tritium mixed gas. The outer wall of the shell 1 is fixed with a plurality of circumferentially extending A first annular guide rail 11 and at least two second annular guide rails 12, each of the first annular guide rails 11 is equipped with a plurality of first running cars 5 that cooperate with the first annular guide rail 11 to generate magnetic levitation force and propulsion force, each The second annular guide rails 12 are equipped with a plurality of second running vehicles 6 that cooperate with the second annular guide rails 12 to generate magnetic levitation force and propulsive force;

[0025] The magnetic levitation ball 3 is located in the casing 1, and includes a first magnetic induction layer 31, a first heat insulation layer 32, an iron core reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com