Electrified lubricating device for isolating switch

A lubricating device and isolating switch technology, which is applied in the direction of switch lubrication, etc., can solve the problems of increasing the safety risk of falling from high places, increasing the working pressure of maintenance personnel, and the loss of users and companies, so as to improve the reliability and reliability of power supply, and increase the reliability of power supply. Better injection effect and better spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

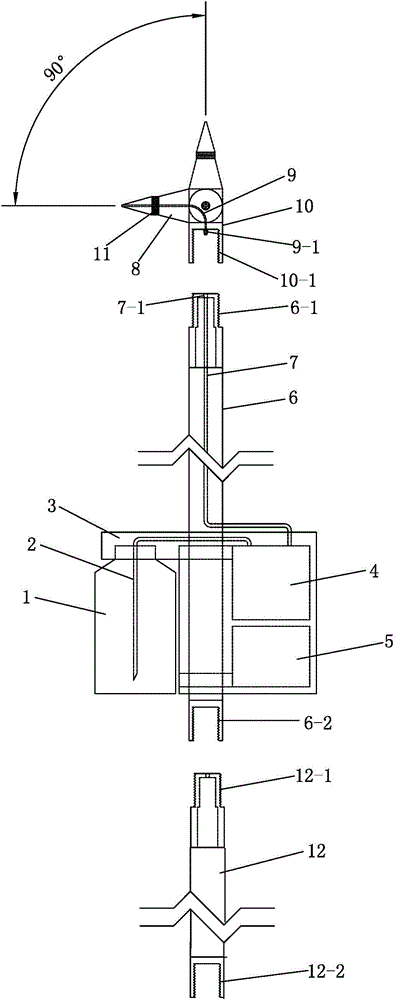

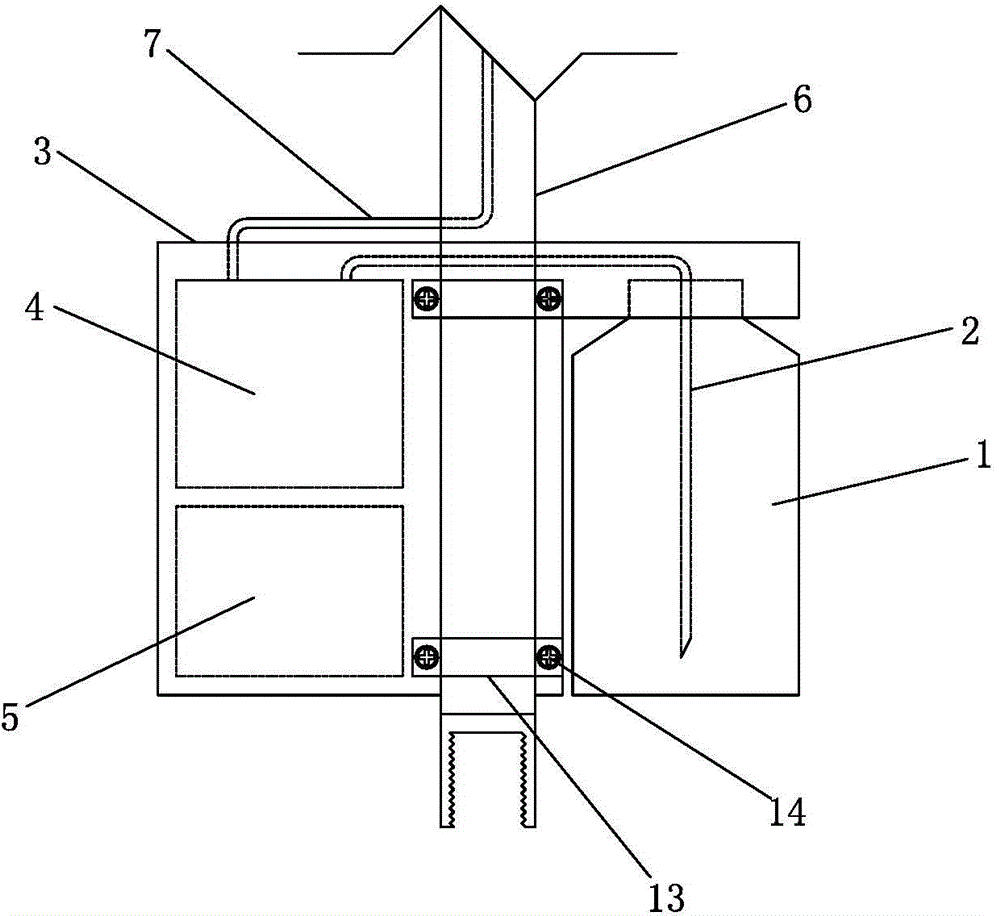

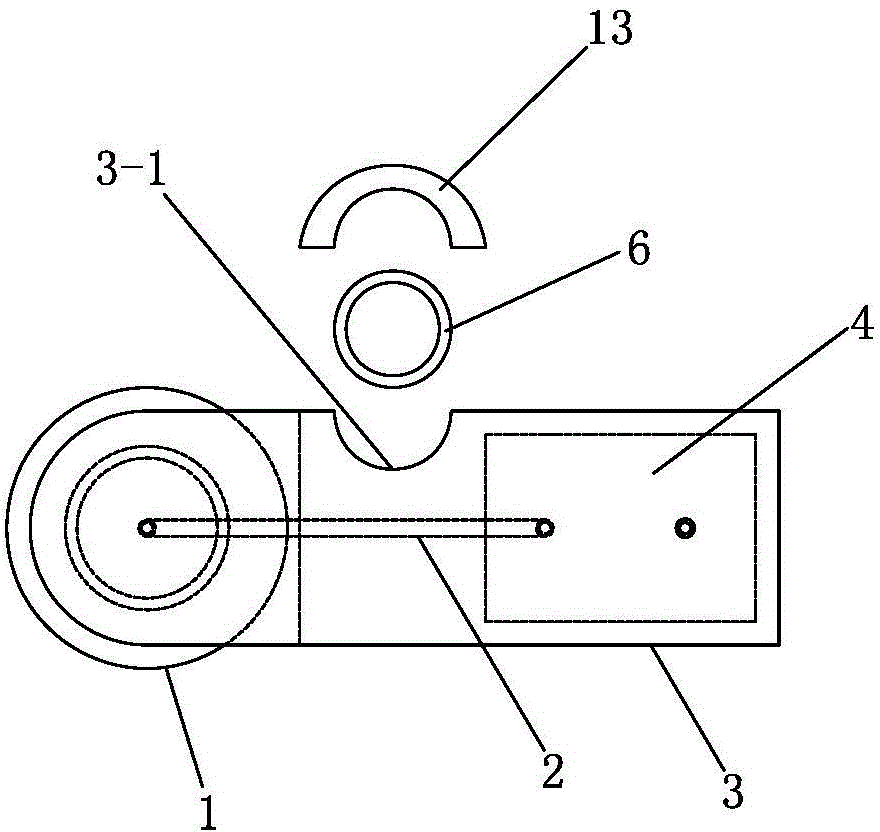

[0027] Examples, see Figure 1-Figure 5 As shown, a live lubricating device for an isolating switch of the present invention includes an oil pump system, a first oil pipe 2, a second oil pipe 7, an insulating pipe 6 and an oil spray nozzle 8, the oil pump system includes an oil storage pot 1 and an oil pump 4, and the oil storage The pot 1 is connected to the oil inlet of the oil pump 4 through the first oil pipe 2; the oil nozzle 8 is attached to one end of the insulating pipe 6, and one end of the second oil pipe 7 is connected to the oil outlet of the oil pump 4, and the other end extends into the insulating pipe 6 , and connect the injector 8.

[0028] In this embodiment, the present invention also includes an adapter 10, and the fuel injection nozzle 8 is rotatably attached to the adapter 10 at a predetermined angle (specifically, the adjustable angle range of the fuel injection nozzle 8 is 0-90° °), the adapter 10 is fixedly connected to one end of the insulating tube 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com