Diode structure for reducing anode hole injection

A hole injection and diode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as large dynamic loss, increased leakage, and increased contact resistance, achieving compact structure, reducing dynamic loss, and reducing hole injection. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

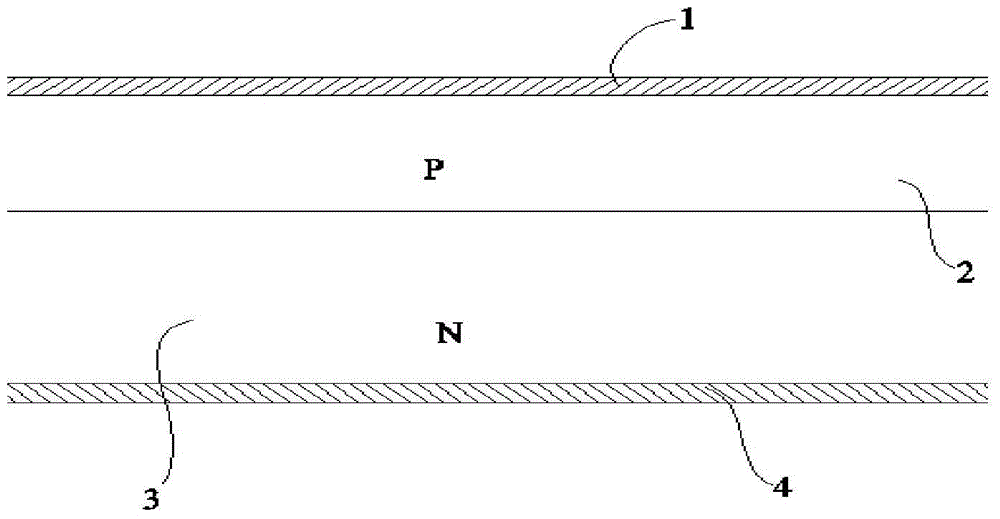

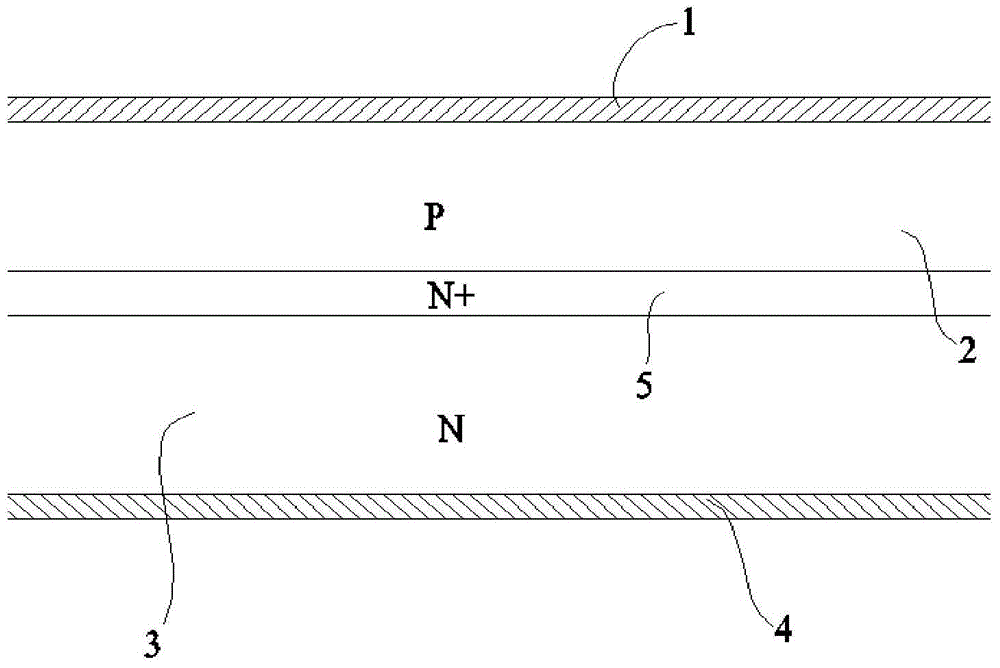

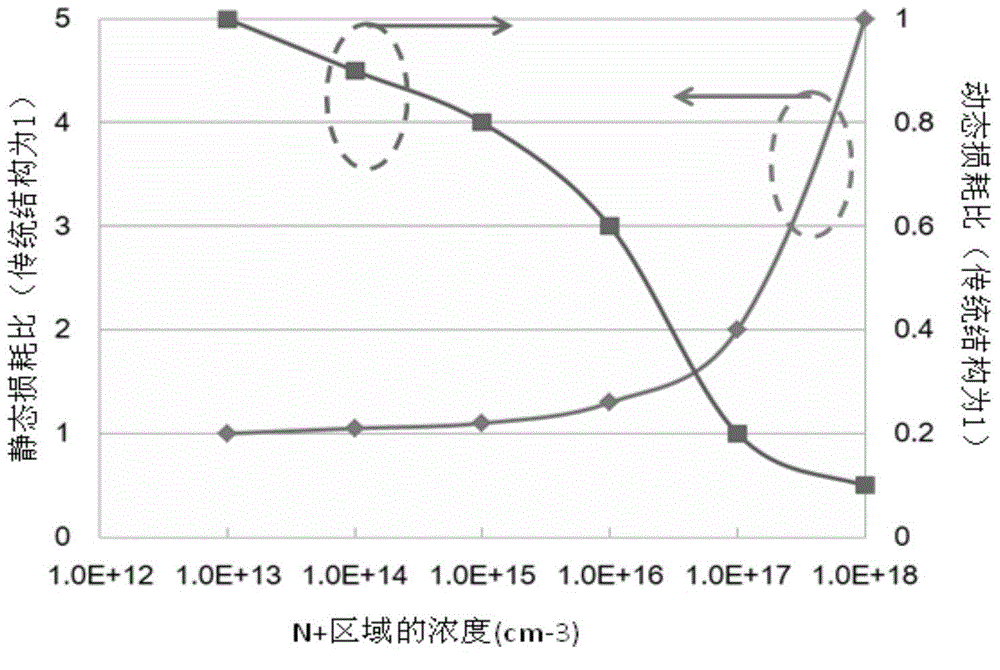

[0013] Such as figure 2 As shown: in order to effectively reduce the dynamic loss of the diode by reducing the anode hole injection, the present invention includes a semiconductor substrate, which includes a P conductive region 2 and an N conductive region 3 for forming a PN junction; in the P An N+ region 5 with a doping concentration higher than that of the N conductive region 3 is disposed between the conductive region 2 and the N conductive region 3 .

[0014] The semiconductor substrate includes a silicon substrate. An anode metal 1 for ohmic contact with the P conductive region 2 is arranged on the front of the semiconductor substrate, and a cathode metal 4 for ohmic contact with the N conductive region 3 is arranged on the back of the semiconductor substrate.

[0015] Specifically, the material of the semiconductor substrate may be silicon, the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com