Reflective layer structure of a light emitting diode

A technology of light-emitting diodes and reflective layers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unstable mirror structure, easy to be oxidized, and low reflectivity, and achieve simple structure, avoid falling off, and high reflectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

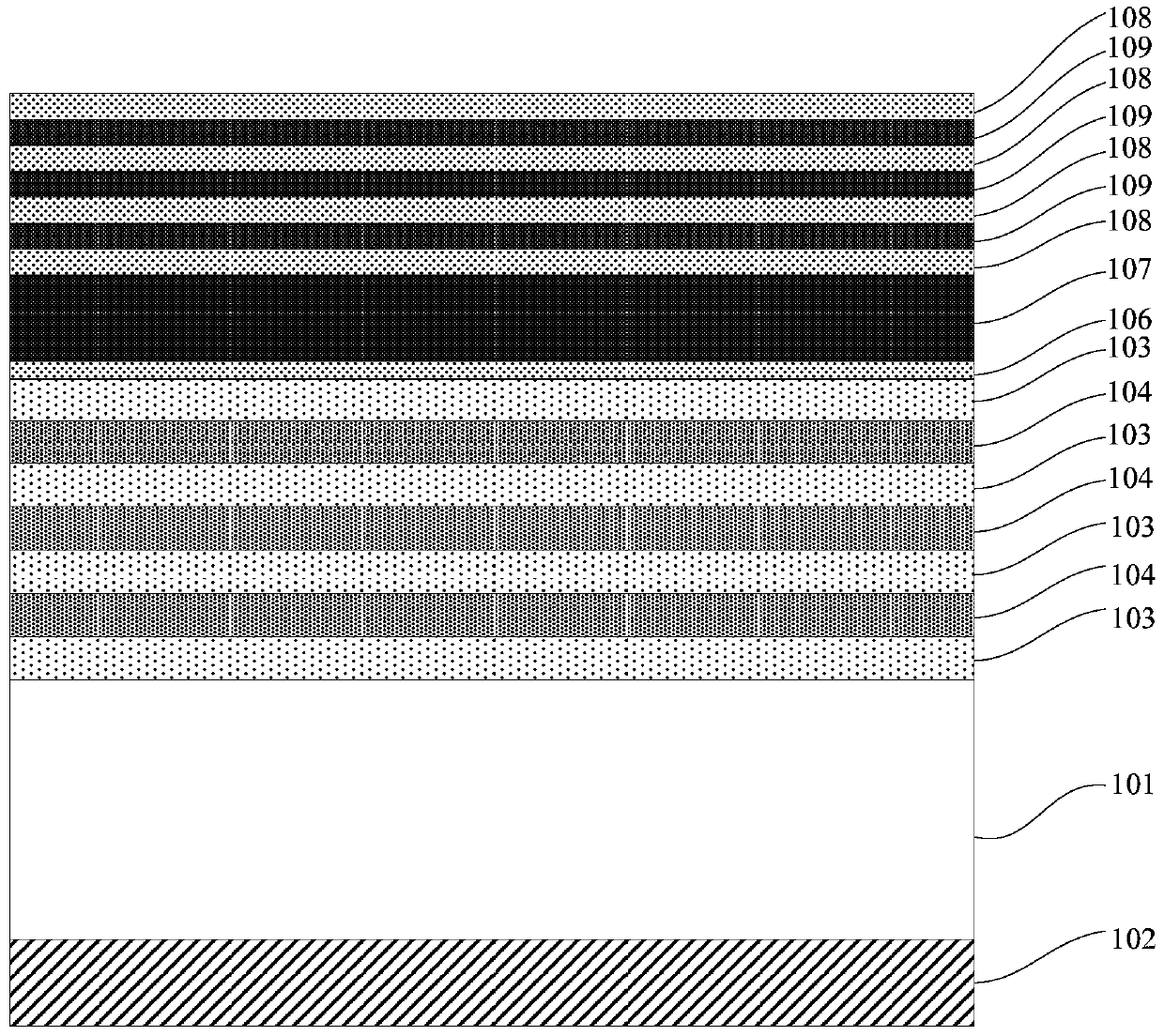

[0038] Such as figure 1 As shown, this embodiment provides a reflective layer structure of a light emitting diode, at least including:

[0039] Dielectric stacks, including alternating layers of SiO 2 Layer 103 with Ti 3 o 5 layer 104, wherein the bottom layer of the dielectric stack is SiO 2 Layer 103;

[0040] The middle Ni layer 106 is combined on the surface of the dielectric stack;

[0041] Ag reflective layer 107, combined on the surface of the middle Ni layer 106;

[0042] The metal stack includes alternately stacked Ni layers 108 and Ag layers 109 , wherein the top layer of the metal stack is the Ni layer 108 .

[0043] The dielectric stack is combined on the back of the thinned sapphire substrate 101 of the light emitting diode, and the front of the sapphire substrate 101 is prepared with a light emitting epitaxial structure 102 . The dielectric stack includes a plurality of alternately stacked SiO 2 Layer 103 with Ti 3 o 5 layer 104, and each layer of SiO ...

Embodiment 2

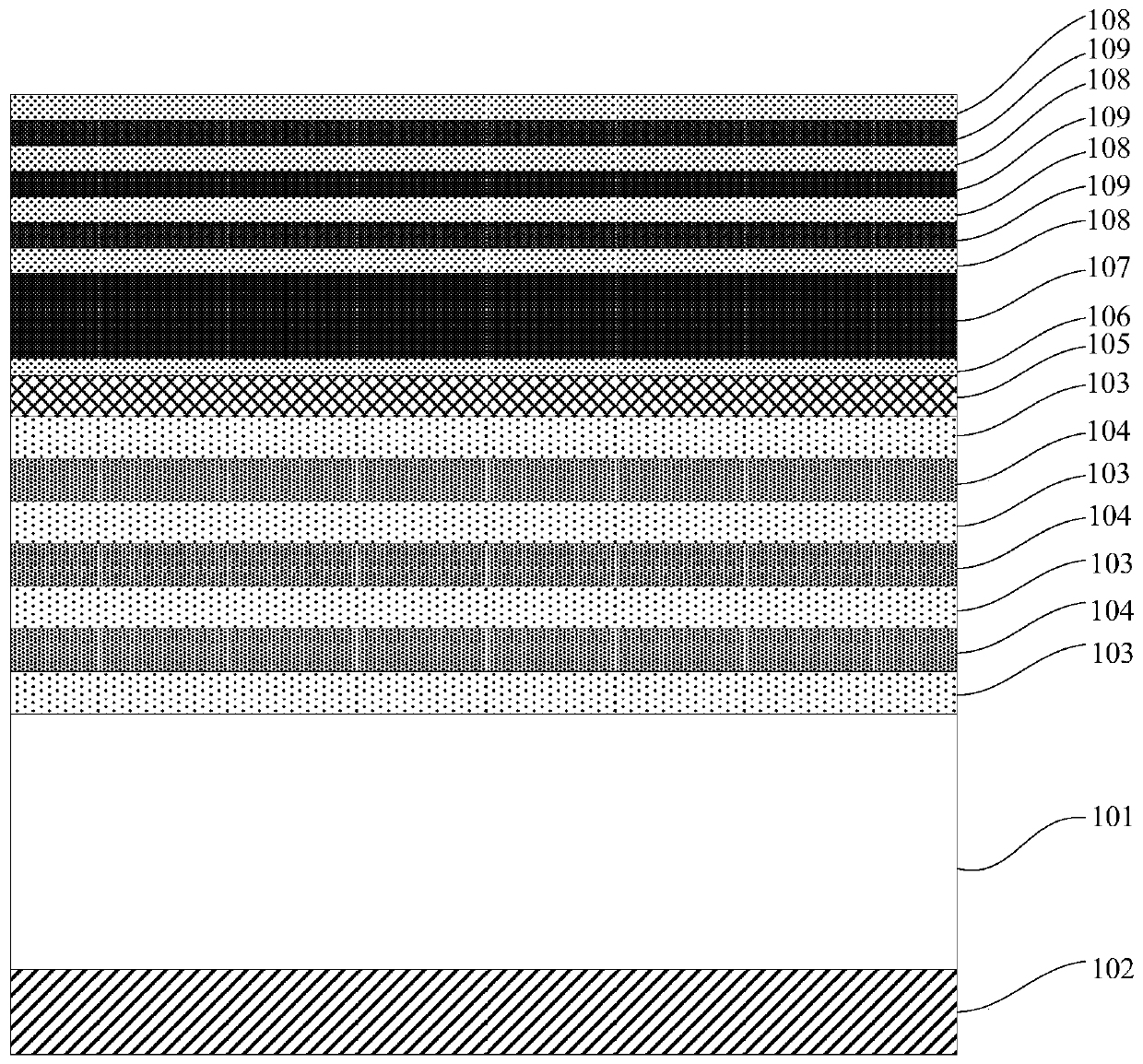

[0049] Such as figure 2 As shown, this embodiment provides a reflective layer structure of a light-emitting diode, the basic structure of which is as in Embodiment 1, wherein the dielectric stack further includes SiO bonded to the top layer 2 Al on the surface of layer 103 2 o 3 layer 105, the Al 2 o 3 The thickness of the layer 105 is not greater than 1 micron, within this thickness range, the reflection effect of the dielectric stack will not be reduced.

[0050] The Al 2 o 3 layer 105, which with the SiO 2 Layer 103 has a higher bonding strength, and the bonding strength with the middle Ni layer 106 is higher than that of SiO 2 layer 103 to be high, therefore, the top SiO 2 Layer 103 first prepares a layer of Al 2 o 3 Layer 105, compared with Embodiment 1, can make the Ag reflective layer 107 stronger.

Embodiment 3

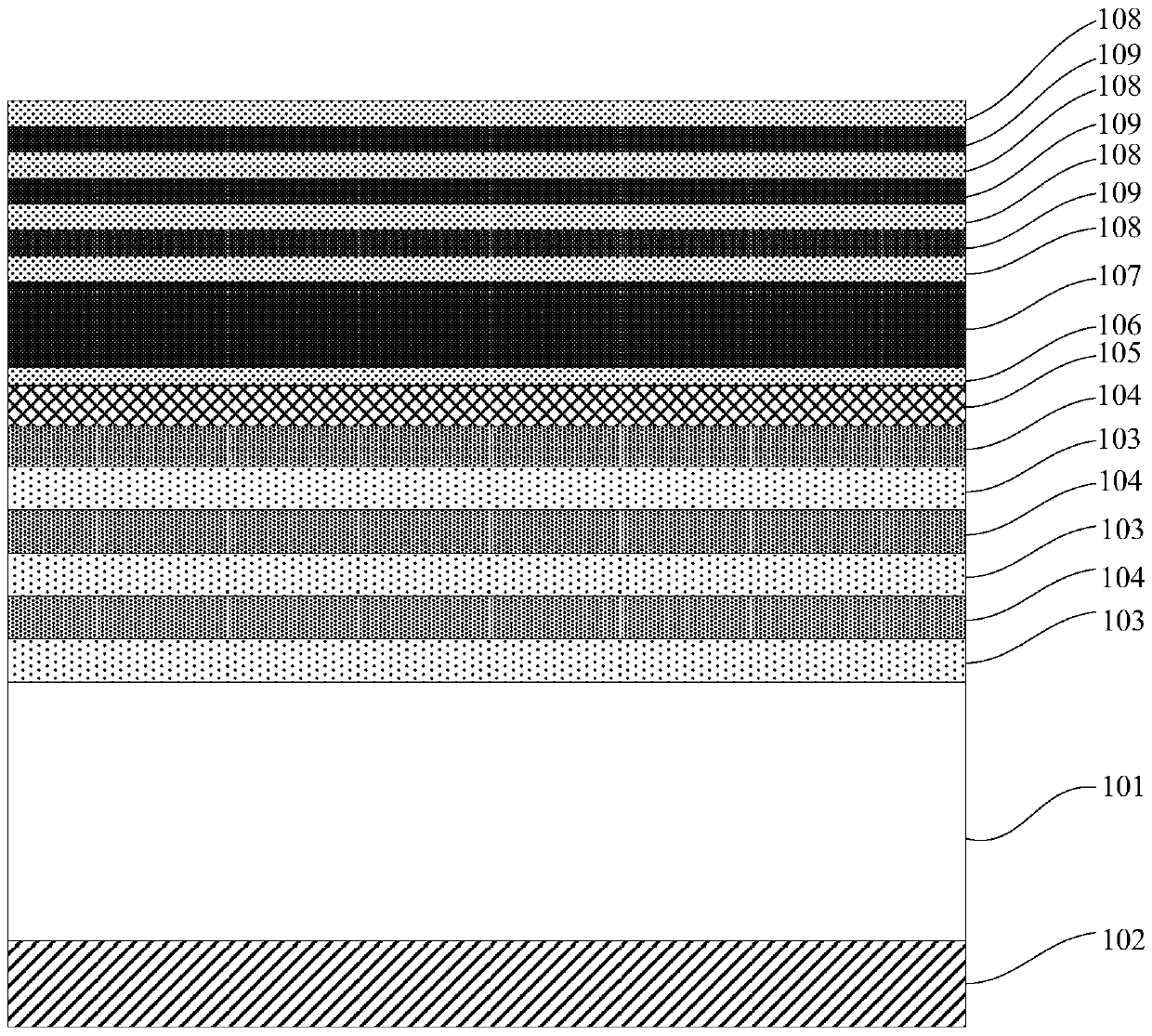

[0052] Such as image 3 As shown, this embodiment provides a reflective layer structure of a light-emitting diode, the basic structure of which is as in Embodiment 1, wherein the top layer of the dielectric stack is Ti 3 o 5 layer 104, and the dielectric stack also includes Ti bonded to the top layer 3 o 5 Al on the surface of layer 104 2 o 3 layer 105, and, the Al 2 o 3 The thickness of layer 105 is no greater than 1 micron.

[0053] The Al 2 o 3 layer 105, which with the Ti 3 o 5 Layer 104 has a higher bonding strength, and the bonding strength with the middle Ni layer 106 is higher than that of SiO 2 layer 103 to be taller, therefore, the top layer of Ti 3 o 5 Layer 104 first prepares a layer of Al 2 o 3 layer 105, used instead of SiO 2 Layer 103, compared with Embodiment 1, can make the Ag reflective layer 107 stronger.

[0054] As mentioned above, the present invention provides a reflective layer structure of a light emitting diode, at least including: a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com