A preparation method of silicon-based composite negative electrode material for lithium ion battery

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effects of alleviating the effect of volume expansion, low cost, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

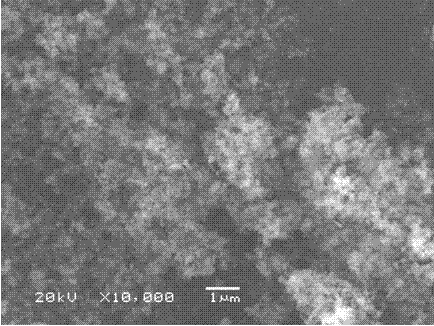

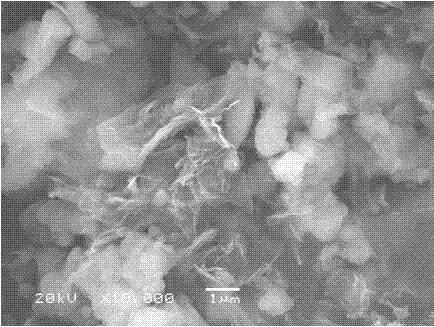

Image

Examples

Embodiment 1

[0026] The method for preparing a silicon-based composite negative electrode material for a lithium ion battery of the present invention includes the following steps:

[0027] (1) In the process of using zircon sand with other chemical and mineral raw materials to produce zirconium chemical products, after the alkali melt or sintered material is treated, a large amount of silicon slag is produced in the process of acidification and silicon removal. Rotary drying at 110°C Dry, ultrasonically break, then add water and ammonium chloride to remove impurities to prepare silica sol; add NaOH to adjust the pH to 9.5, add a small amount of flocculant Al 2 (SO 4 ) 3 (Mass ratio SiO 2 : Al 2 (SO 4 ) 3 =1:0.06), increase the temperature to 85°C, add a small amount of polyethylene glycol (volume 10% of the total solvent volume, average molecular weight 200), stir for 60min, then stand for 30min, wash and centrifuge. The separated hydrated silica is calcined at 650℃ to obtain silica, which is ...

Embodiment 2

[0032] The method for preparing a silicon-based composite negative electrode material for a lithium ion battery of the present invention includes the following steps:

[0033] (1) In the process of using zircon sand with other chemical and mineral raw materials to produce zirconium chemical products, after the alkali melt or sintered material is treated, a large amount of silicon slag is produced in the acidification and desiliconization process. Rotary drying at 120℃ Dry, ultrasonically break, then add water and ammonium chloride to prepare silica sol; add NaOH to adjust the pH to 9.5, add a small amount of flocculant Al 2 (SO 4 ) 3 (Mass ratio SiO 2 : Al 2 (SO 4 ) 3 =1:0.06), increase the temperature to 85°C, add a small amount of polyethylene glycol (volume 10% of the total solvent volume, average molecular weight 200), stir for 60min, then stand for 30min, wash and centrifuge. The hydrated silica obtained after separation is calcined at 800°C to obtain silica, which is activat...

Embodiment 3

[0038] The method for preparing a silicon-based composite negative electrode material for a lithium ion battery of the present invention includes the following steps:

[0039] (1) In the process of using zircon sand with other chemical and mineral raw materials to produce zirconium chemical products, after the alkali melt or sintered material is treated, a large amount of silicon slag is produced in the process of acidification and desiliconization. Rotary drying at 130°C Dry, ultrasonically break, then add water and ammonium chloride to prepare silica sol; add NaOH to adjust the pH to 9.5, add a small amount of flocculant Al 2 (SO 4 ) 3 (Mass ratio SiO 2 : Al 2 (SO 4 ) 3 =1:0.06), increase the temperature to 85°C, add a small amount of polyethylene glycol (volume 10% of the total solvent volume, average molecular weight 200), stir for 60min, then stand for 30min, wash and centrifuge. The hydrated silica obtained after separation is calcined at 750°C to obtain silica, which is act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com