Soil covering type broadcast seeder

A covering type, soil layer technology, applied in sowing seeders, excavation/covering trenches, planting methods, etc., can solve the problems of reduced wheat yield, uneven thickness, lack of crushing quality, etc., saving labor and time, promoting The effect of wheat development and design is reasonable and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

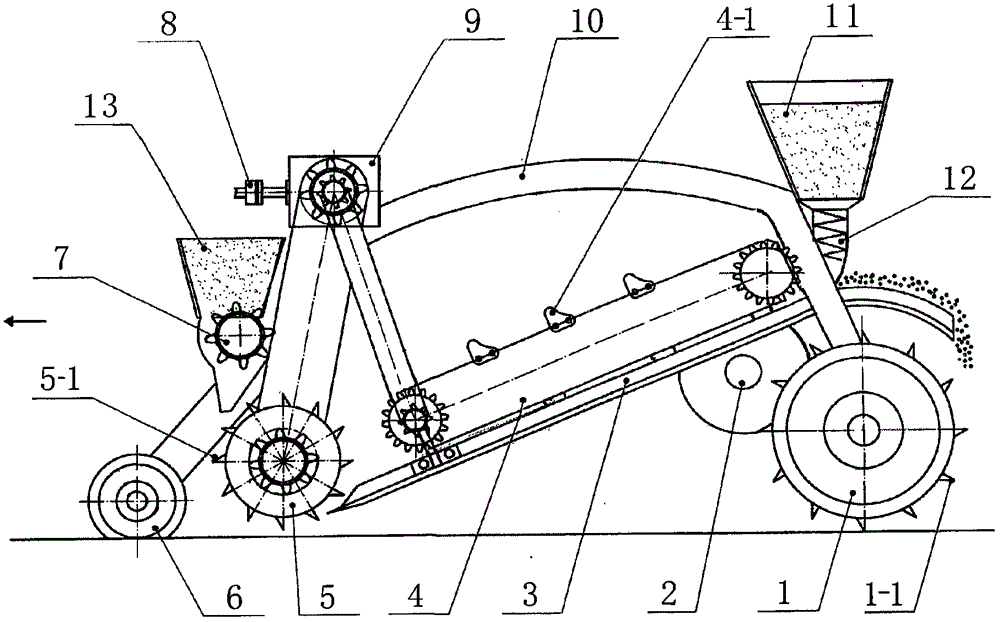

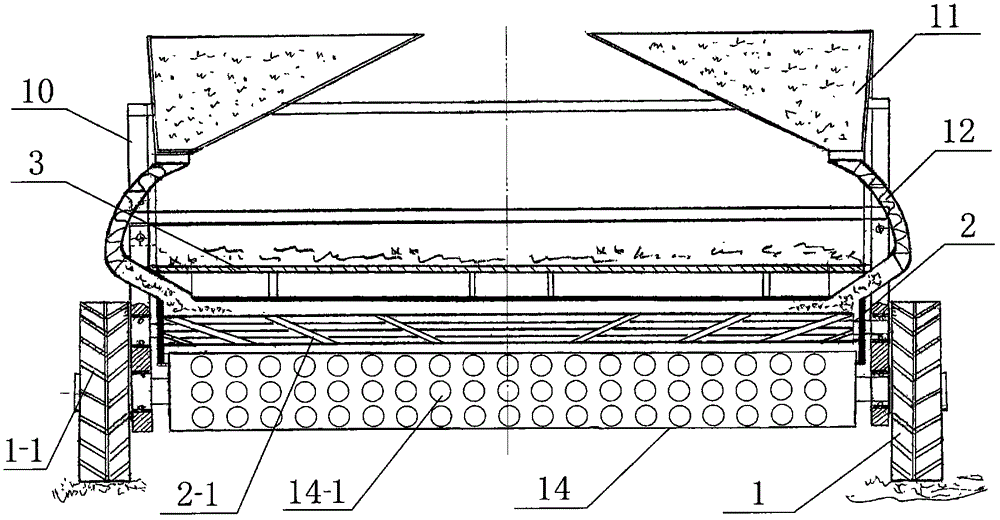

[0021] The invention is a soil layer covering type spreading machine. Its structure see figure 1 , figure 2 . This spreader follows the direction of travel during work ( figure 1 The direction indicated by the arrow on the left), the left is the front, and the right is the rear. The local layer covering spreader is mainly composed of walking wheel 1, material guide shaft 2, soil layer conveying groove 3, soil layer conveying mechanism 4, soil sending rotary roller 5, external power input shaft 8, main input box 9, frame 10, The seed bin 11, the feed pipe 12, the fertilizer bin 13 and the seed spreading roller 14 are composed.

[0022] This spreader whole is all supported by frame 10. Two road wheels 1 are symmetrically installed on the bottom of the frame 10 rear, and an anti-skid tooth bar 1-1 is provided at the road wheel 1 outer ring, so that the spreading machine can move forward stably during work. The seed spreading roller 14 is installed on the central axis betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com