A rice pretreatment device

A pretreatment device and paddy technology, applied in the direction of grain processing, grain milling, application, etc., can solve problems such as clogging rice mills, large dust, and affecting the health of workers, and achieve the effect of reducing injuries and small dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

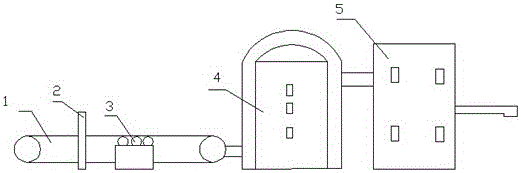

[0024] The present embodiment comprises paddy conveying mesh belt 1, cleaning device 2, drying device 3, paddy hoist 4 and destoner 5, and described cleaning device 2 and drying device 3 are respectively installed on the top of rice conveying mesh belt 1 and Below, cleaning device 2 is positioned at the front of drying device 3, and described paddy hoist 4 is installed in the rear of drying device 3, and the feeding port of paddy hoist 4 is positioned at the below of paddy conveying mesh belt 1 discharge end, described The discharge port of the paddy hoist 4 is connected with the feed port of the stone remover 5 .

Embodiment 2

[0026] The present embodiment comprises paddy conveying mesh belt 1, cleaning device 2, drying device 3, paddy hoist 4 and destoner 5, and described cleaning device 2 and drying device 3 are respectively installed on the top of rice conveying mesh belt 1 and Below, cleaning device 2 is positioned at the front of drying device 3, and described paddy hoist 4 is installed in the rear of drying device 3, and the feeding port of paddy hoist 4 is positioned at the below of paddy conveying mesh belt 1 discharge end, described The discharge port of the paddy hoist 4 is connected with the feed port of the stone remover 5 .

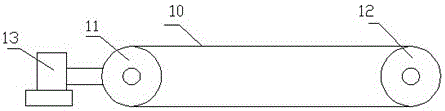

[0027] Rice conveying net belt 1 comprises conveying net 10, driving roller 11, driven roller 12 and driving motor 13, and conveying net 10 is sleeved on driving roller 11 and driven roller 12, and driving roller 11 is connected with the output shaft of driving motor 13 connect.

Embodiment 3

[0029] The present embodiment comprises paddy conveying mesh belt 1, cleaning device 2, drying device 3, paddy hoist 4 and destoner 5, and described cleaning device 2 and drying device 3 are respectively installed on the top of rice conveying mesh belt 1 and Below, cleaning device 2 is positioned at the front of drying device 3, and described paddy hoist 4 is installed in the rear of drying device 3, and the feeding port of paddy hoist 4 is positioned at the below of paddy conveying mesh belt 1 discharge end, described The discharge port of the paddy hoist 4 is connected with the feed port of the stone remover 5 .

[0030] Rice conveying net belt 1 comprises conveying net 10, driving roller 11, driven roller 12 and driving motor 13, and conveying net 10 is sleeved on driving roller 11 and driven roller 12, and driving roller 11 is connected with the output shaft of driving motor 13 connect.

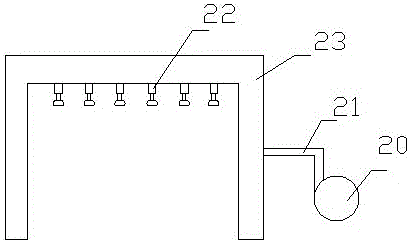

[0031] The cleaning device 2 includes a water pump 20, a water pipe 21, a nozzle 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com