Hybrid vehicle expansion tank installation structure

A technology for hybrid electric vehicles and installation structures, which is applied to the power unit, the arrangement of the cooling combination of the power unit, and vehicle components, etc., and can solve problems such as unsatisfactory fixing effects, modal test characteristics, strength and space layout that cannot meet the requirements, etc. , to achieve ideal fixing effect, enhanced strength and rigidity, convenient and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

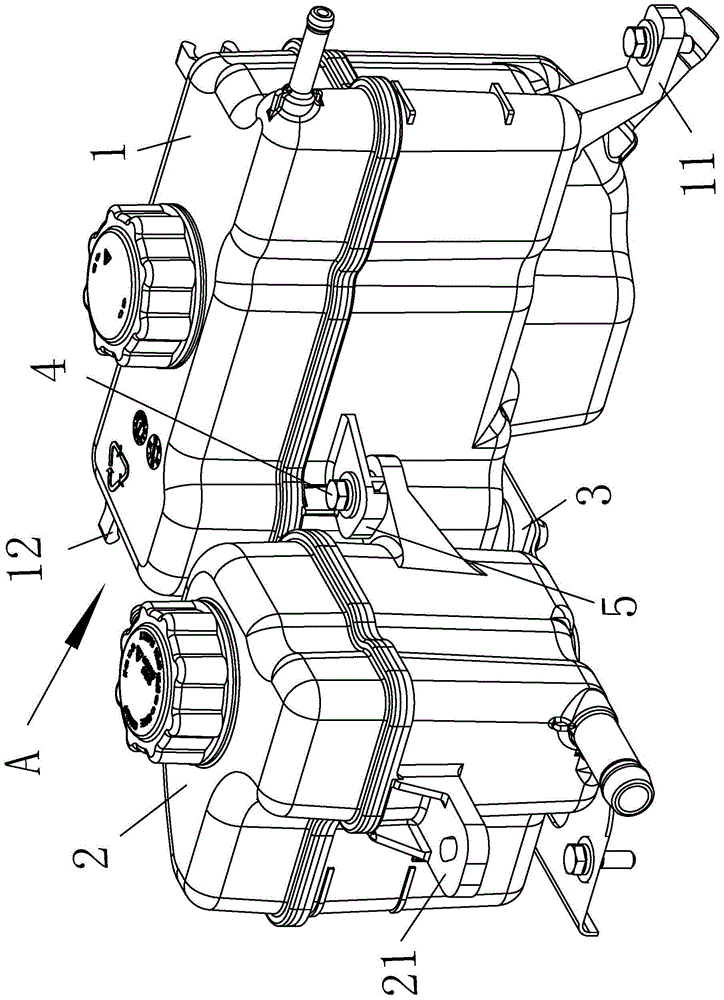

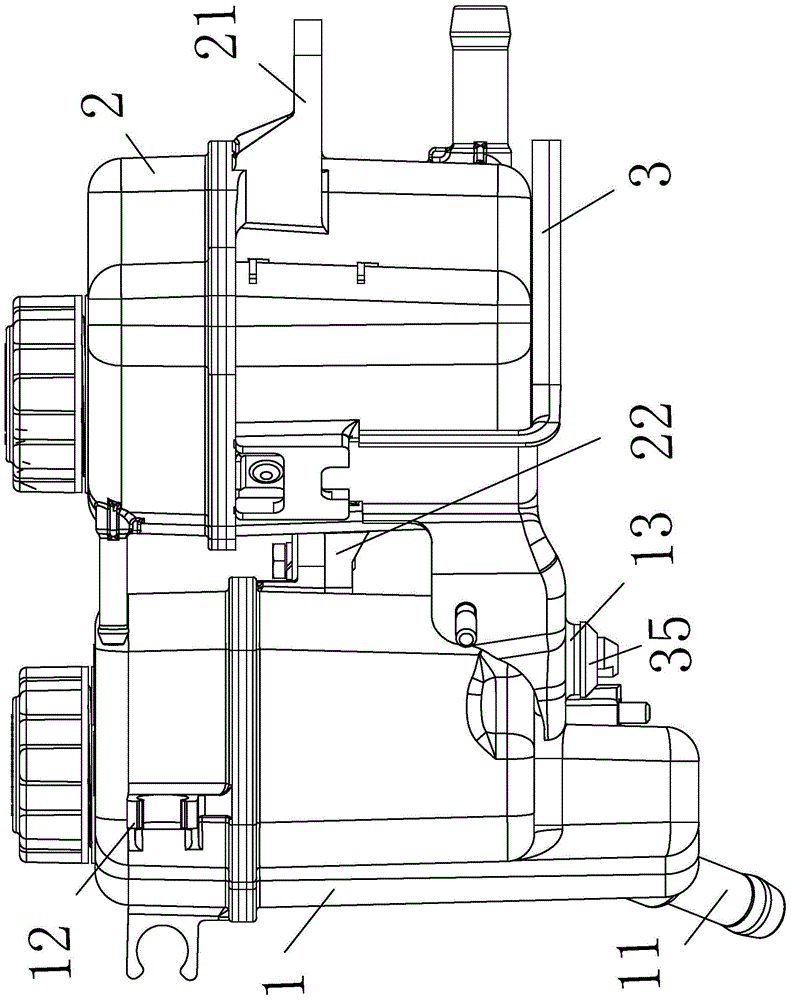

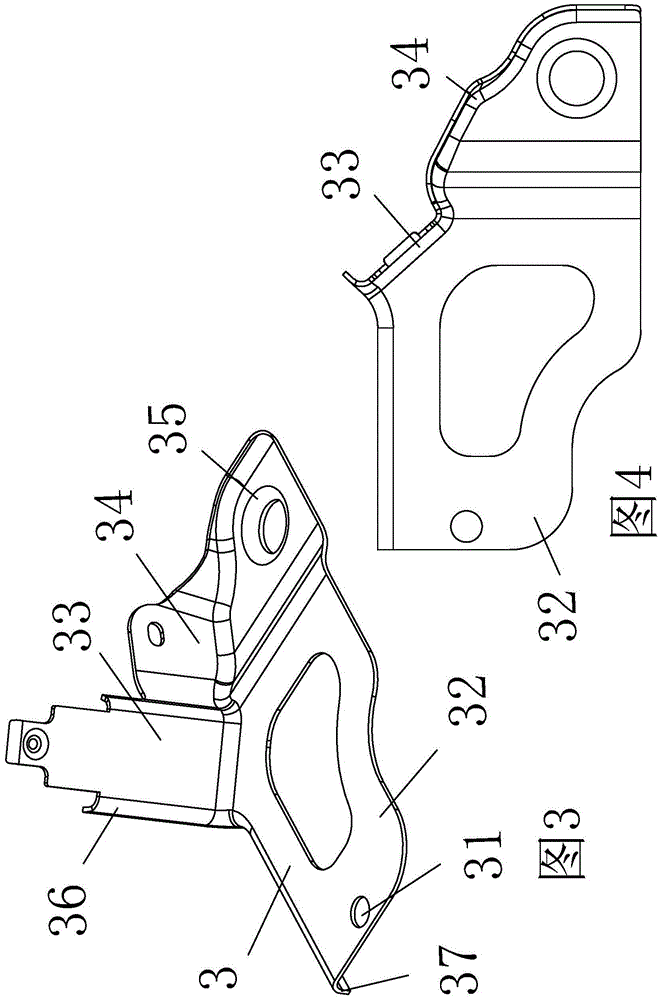

[0018] as attached figure 1 As shown in accompanying drawing 4: a kind of hybrid vehicle expansion tank installation structure, comprises the engine expansion tank 1 that is provided with a lower fixing lug 11 and one side end and rear end respectively is provided with a fixing block 12 at the lower front end, PEU expansion tank 2. Fixing bracket 3; PEU expansion tank 2 and engine expansion tank 1 are arranged in an L shape, one side end of PEU expansion tank 2 is opposite to the rear of the other side end of engine expansion tank 1; the other side end of PEU expansion tank 2 A side fixing ear 21 is provided; the front end of the PEU expansion tank 2 and the other side end of the engine expansion tank 1 are each provided with a connecting ear 5 connected by a connecting bolt 4; the fixing bracket 3 includes a bottom mounting hole 31 and Bottom plate 32 screwed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com