Anti-hypsokinesis safe control device of crane arm frame

A technology of safety control and anti-backward tilt, applied in cranes and other directions, can solve the problems of limited detection distance, difficult adjustment and high cost, and achieve the effect of high degree of generalization, not easy to interfere, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

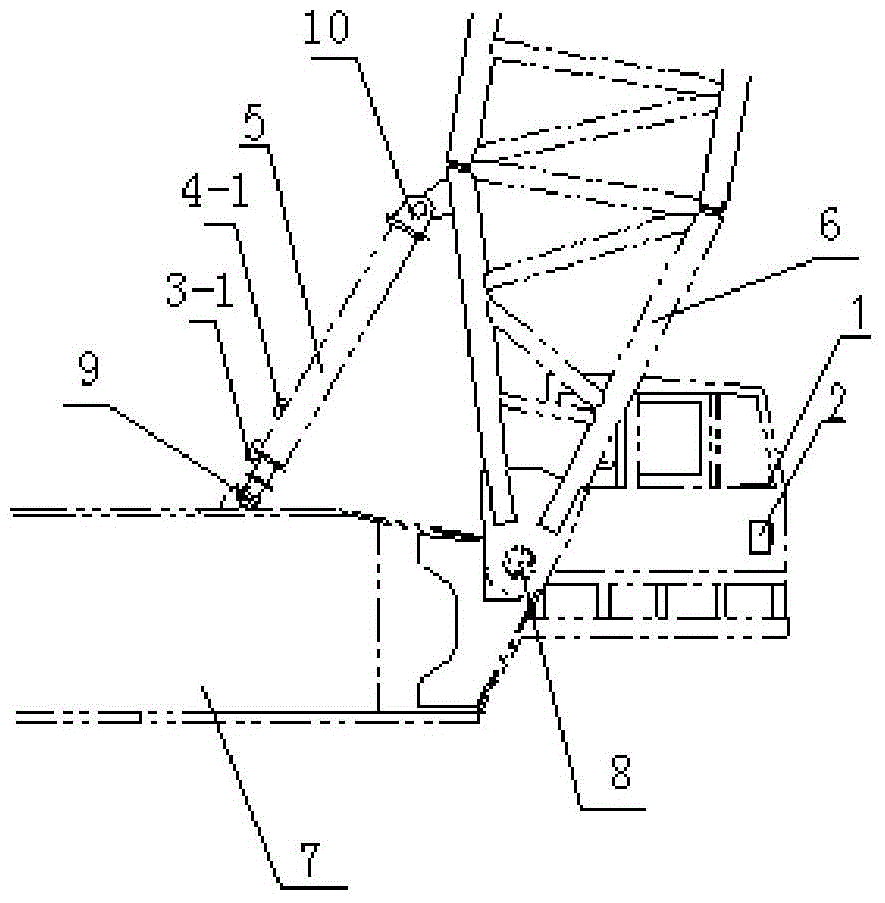

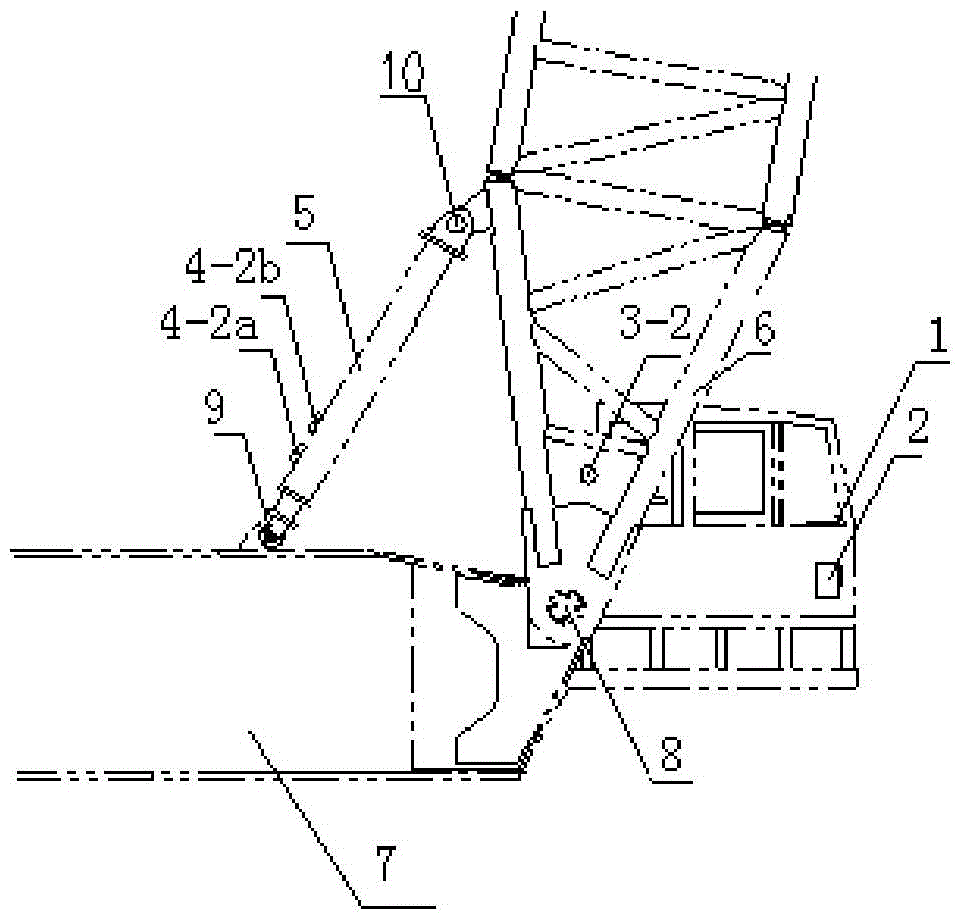

[0021] See figure 2 , A crane boom anti-backward safety control device of the present invention includes a display 1, a controller 2, and an angle sensor 3-2 linked with the boom 6 to measure the angle of the boom 6; the boom 6 and the turntable 7 the first hinge point 8; anti-backward 5 and the second hinge point 9 of the turntable 7; anti-backward 5 and the third hinge point 10 of the boom 6; low pressure alarm pressure switch 4 installed on the anti-backward 5 -2a and high pressure alarm pressure switch 4-2b.

[0022] The angle sensor 3-2 detects the angle of the boom 6 in real time, and sends the angle current signal to the controller 2.

[0023] The controller 2 receives the angle signal of the boom 6 detected by the angle sensor 3-2, and combines th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com