High-efficient energy-saving reverse osmosis filtration system

A filtration system, high-efficiency and energy-saving technology, applied in the field of water treatment, can solve the problems of increased cost of ion exchangers, high energy consumption of equipment, large labor input, etc., to eliminate capital and labor input, reduce production costs, and reduce water and electricity consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

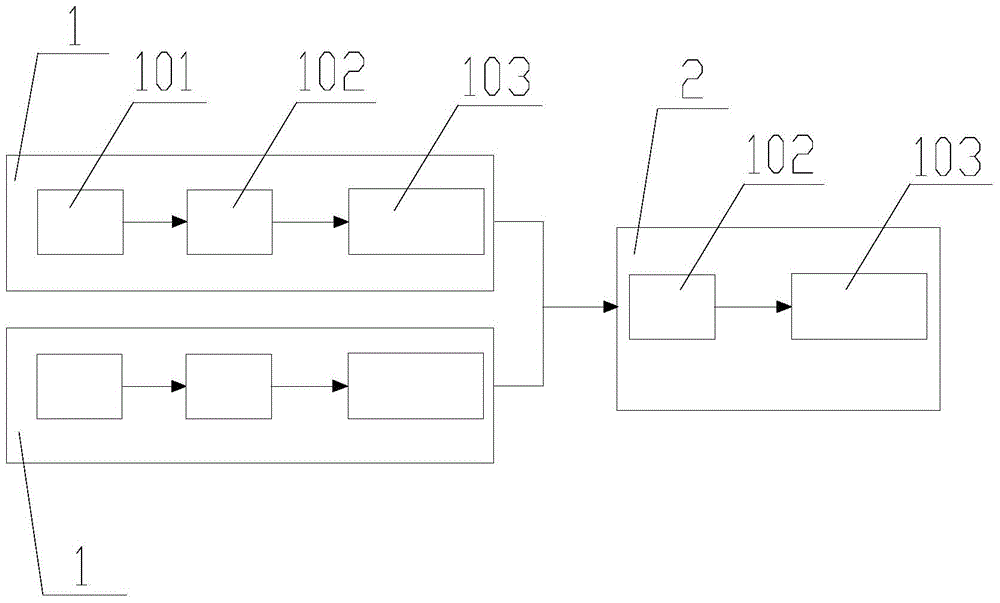

[0010] Such as figure 1 A high-efficiency and energy-saving reverse osmosis filtration system is shown, which is characterized in that it is composed of a secondary filtration system 2 and several primary filtration systems 1, and any primary filtration system 1 is fixedly connected to the secondary filtration system 2 through pipelines , the filter system 1 at any stage is provided with several sand filters 101, several protectors 102 and several groups of reverse osmosis filters 103, and the sand filters 101, protectors 102 and reverse osmosis filters 103 are fixed by pipelines The secondary filtration system 2 is provided with several protectors 102 and several groups of permeation filters 103, and the protectors 102 and reverse osmosis filters 103 are fixedly connected through pipelines.

[0011] Working method: when the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com