cu‑ni‑si alloy material and cooling roll sleeves containing the alloy

A technology of alloy materials and cooling rolls, applied in high-strength copper alloy materials and application fields, can solve the problems of low strength of chromium-zirconium copper and poisonous elements in beryllium copper, and achieve reduced surface roughness, low cost and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

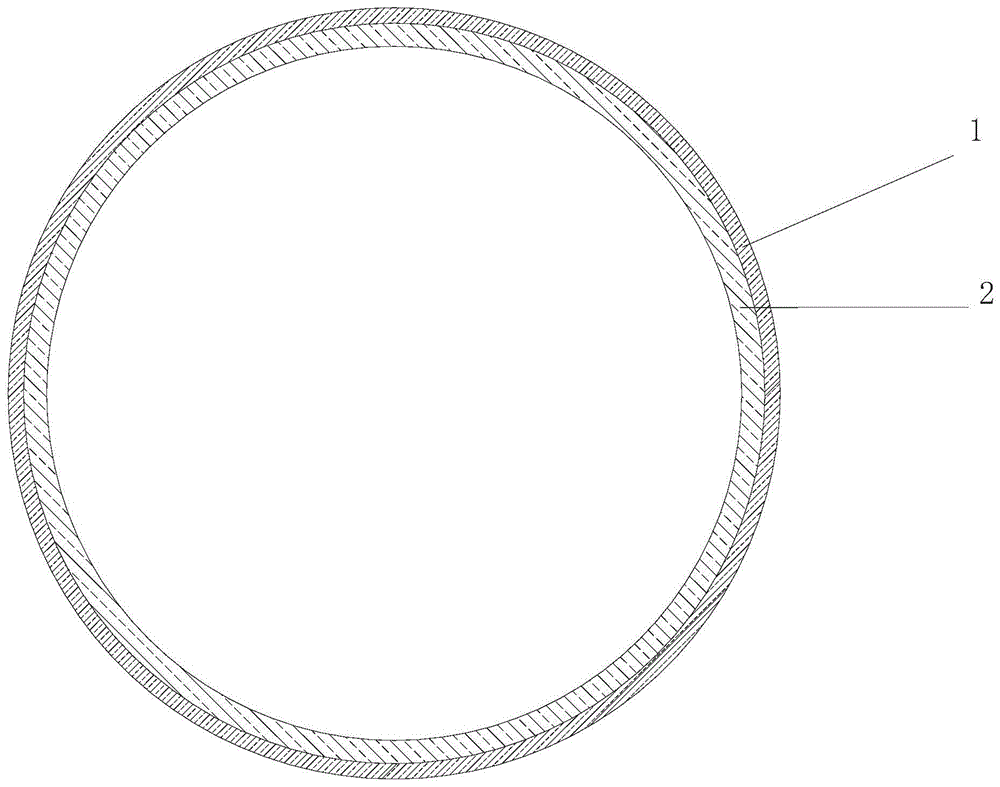

Image

Examples

preparation example Construction

[0031] The preparation method of the Cu-Ni-Si alloy material includes the steps of smelting, casting, forging and heat treatment, wherein:

[0032] In the smelting and casting steps, the simple substance of each component is placed in an induction melting furnace for smelting according to a prescribed composition ratio, and then the molten Cu-Ni-Si alloy liquid is poured to obtain a casting billet;

[0033] In the forging step, the casting billet is hot forged in a temperature range of 720-920°C (for example, 730°C, 750°C, 800°C, 850°C, 870°C, 900°C, 910°C), and forged in this section Ni 2 Si crystal grains are uniform and refined to improve material strength;

[0034] In the heat treatment step, aging treatment is performed after solid solution, wherein the solid solution temperature is 820-980°C (for example, 830°C, 860°C, 880°C, 910°C, 950°C, 970°C), and the aging temperature is 420°C. ~500℃ (such as 430℃, 450℃, 480℃, 490℃), this heat treatment method can precipitate Ni for stren...

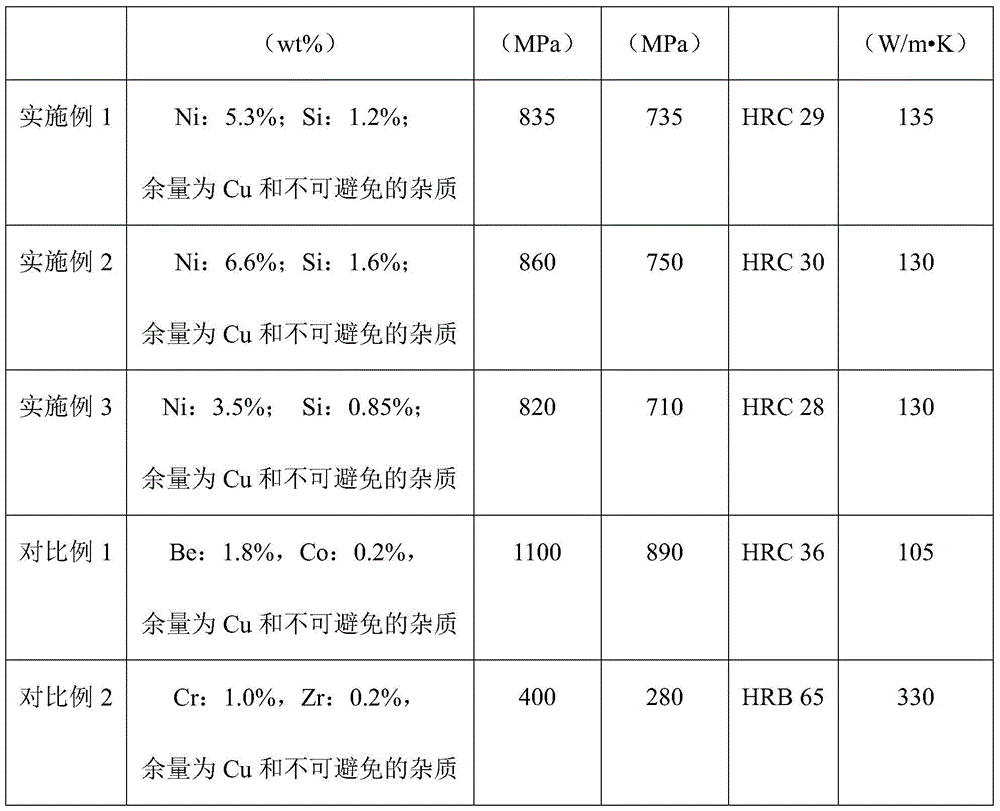

Embodiment 1

[0038] The Cu-Ni-Si alloy prepared in this embodiment is composed of the following components by weight percentage: Ni: 5.3%; Si: 1.2%; the balance is Cu and unavoidable impurities.

[0039] The preparation method of the Cu-Ni-Si alloy material in this embodiment is as follows:

[0040] (1) Smelting and casting According to the above-mentioned component weight ratio, nickel powder, silicon powder and copper block are put into an induction melting furnace for smelting, and then the molten Cu-Ni-Si alloy liquid is poured to obtain a casting billet;

[0041] (2) Forging: Hot forging the casting billet and cooling to room temperature after hot forging, where the initial forging temperature is 900°C and the final forging temperature is 800°C; punching and reaming must be completed during the forging process;

[0042] (3) The heat treatment adopts a solid solution + aging heat treatment process. The hot forged forgings are heated to 900°C for solution treatment, and after holding for 2 hours...

Embodiment 2

[0045] The Cu-Ni-Si alloy prepared in this embodiment is composed of the following components by weight percentage: Ni: 6.6%; Si: 1.6%; the balance is Cu and unavoidable impurities.

[0046] The preparation method of the Cu-Ni-Si alloy material in this embodiment is the same as that of embodiment 1, and the thickness of the obtained ring-shaped alloy material is the same as that of embodiment 1. See Table 1 for the properties of the alloy material prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com