A kind of silk polyphenol finishing agent and preparation method thereof

The technology of finishing agent and silk is applied in the field of silk polyphenol finishing agent and its preparation, which can solve the problems of low anti-wrinkle strength and poor antibacterial effect, and achieve the effect of improving antibacterial strength and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

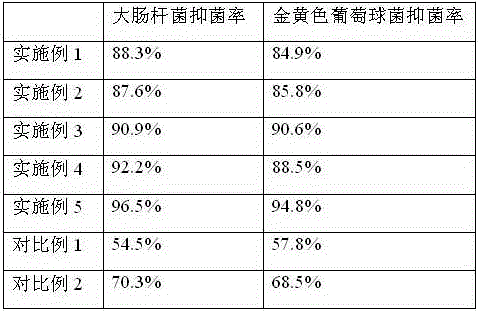

Examples

Embodiment 1

[0048] (1) Take commelina, vacuum dry, pulverize after vacuum drying, then use 40wt% ethanol aqueous solution to stir and extract, the weight ratio of solid to liquid is 1:6, the extraction time is 3 hours, the extraction temperature is 55 °C, and centrifuged after extraction , take the supernatant and carry out vacuum concentration, and collect the concentrate after vacuum concentration, which is Commelina 40wt% ethanol water extract; (2) After pulverizing the August leaves, stir and extract with ethanol, the weight ratio of solid to liquid is 1: 5. The extraction time is 4 hours, the extraction temperature is 45°C, centrifuged after extraction, the supernatant is taken for vacuum concentration, and after vacuum concentration, the August berry concentrate is collected, which is the August berry ethanol extract; (3) by weight percentage Take the following components, tea polyphenols is 8wt%, commelina 40wt% ethanol water extract is 10wt%, Augustia ethanol extract is 9wt%, sodiu...

Embodiment 2

[0050] (1) Take commelina, vacuum dry, pulverize after vacuum drying, then use 40wt% ethanol aqueous solution to stir and extract, the weight ratio of solid to liquid is 1:6, the extraction time is 3 hours, the extraction temperature is 55 °C, and centrifuged after extraction , take the supernatant and carry out vacuum concentration, and collect the concentrate after vacuum concentration, which is Commelina 40wt% ethanol water extract; (2) After pulverizing the August leaves, stir and extract with ethanol, the weight ratio of solid to liquid is 1: 5. The extraction time is 4 hours, the extraction temperature is 45°C, centrifuged after extraction, the supernatant is taken for vacuum concentration, and after vacuum concentration, the August berry concentrate is collected, which is the August berry ethanol extract; (3) by weight percentage Take the following ingredients, tea polyphenols is 3wt%, commelina 40wt% ethanol water extract is 4wt%, Augustia ethanol extract is 3wt%, sodiu...

Embodiment 3

[0052] (1) Take commelina, vacuum dry, pulverize after vacuum drying, then use 40wt% ethanol aqueous solution to stir and extract, the weight ratio of solid to liquid is 1:6, the extraction time is 3 hours, the extraction temperature is 55 °C, and centrifuged after extraction , take the supernatant and carry out vacuum concentration, and collect the concentrate after vacuum concentration, which is Commelina 40wt% ethanol water extract; (2) After pulverizing the August leaves, stir and extract with ethanol, the weight ratio of solid to liquid is 1: 5. The extraction time is 4 hours, the extraction temperature is 45°C, centrifuged after extraction, the supernatant is taken for vacuum concentration, and after vacuum concentration, the August berry concentrate is collected, which is the August berry ethanol extract; (3) by weight percentage Take the following components, tea polyphenols is 4wt%, commelina 40wt% ethanol water extract is 9wt%, Augustia ethanol extract is 5wt%, sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com