High-density composite fiberboard

A composite fiber, high-density technology, applied in reed/straw treatment, pretreatment of molding materials, lamination, etc., can solve the problems of insufficient service life and high production cost of high-density composite fiberboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

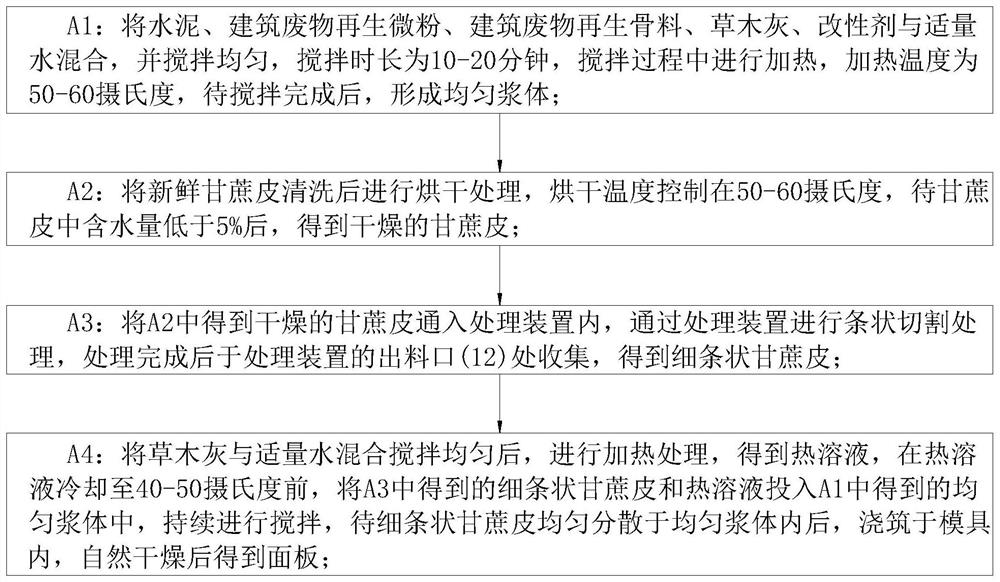

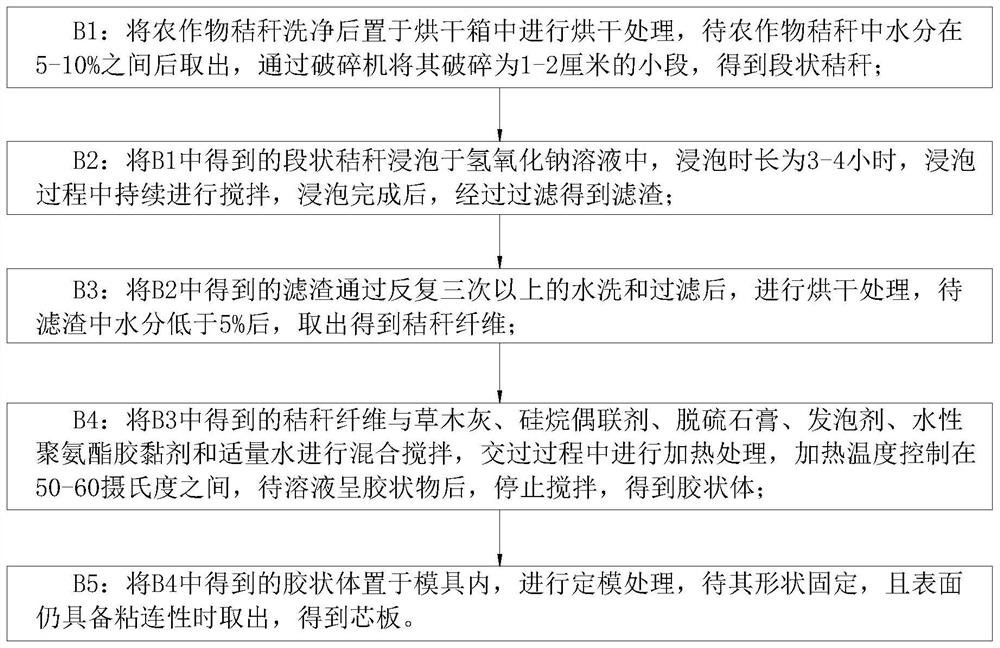

[0060] As an embodiment of the present invention, the production method of high-density composite fiberboard comprises the following steps:

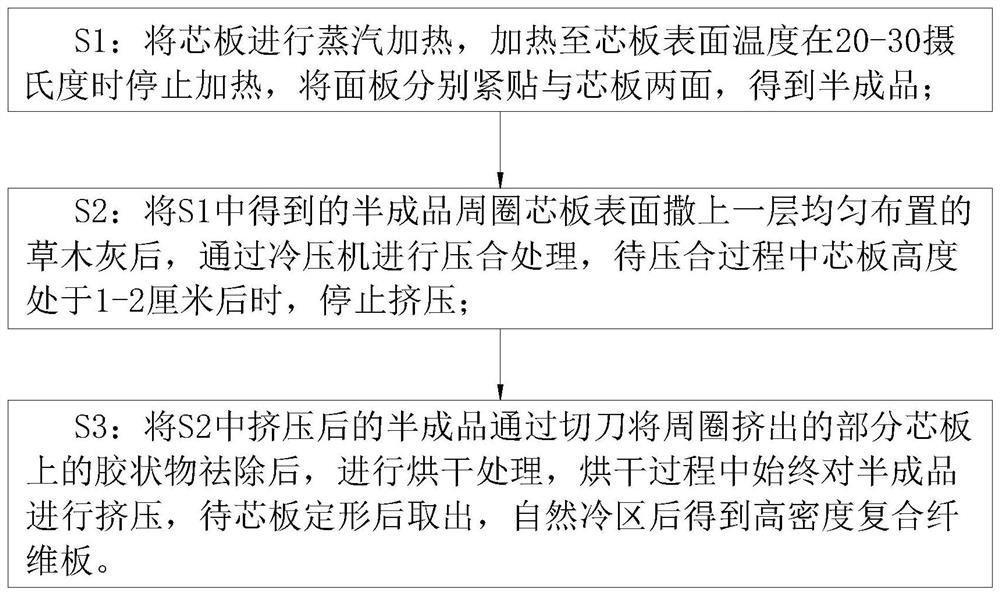

[0061] S1: Heat the core board with steam, stop heating when the surface temperature of the core board is 20-30 degrees Celsius, and stick the panel to the two sides of the core board respectively to obtain a semi-finished product. When the surface temperature of the core board is 20-30 degrees Celsius, you can Ensure the highest bonding strength of the core board, while the core board itself is a paste;

[0062] S2: Sprinkle a layer of evenly distributed plant ash on the surface of the semi-finished peripheral core plate obtained in S1, and press it through a cold press. When the core plate height is 1-2 cm during the pressing process, stop extrusion Pressing, through the cold press to carry out the pressing process, can effectively increase the density of the core board and the panel, and at the same time improve the adhesion strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com