Lightweight ceiling

A ceiling, lightweight technology, used in building components, covering/lining, construction, etc., can solve the problems of heavy weight, difficult to cut, dust falling off, etc., to achieve the effect of simple structure, elegant and beautiful appearance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be further described below in conjunction with the drawings and specific implementations.

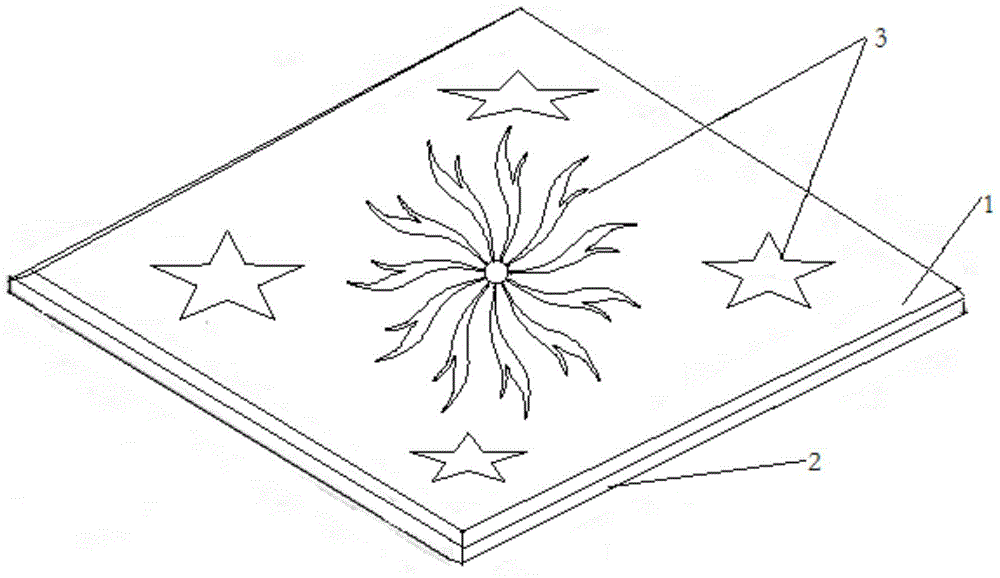

[0012] Such as figure 1 As shown, the invention of the present invention includes a substrate. The substrate includes a polystyrene top plate 1 and a composite plate 2. The back of the polyethylene top plate 1 and the composite plate 2 are bonded together by a sealant to form a complete ceiling. The polystyrene top plate 1 is made of polystyrene through a foaming process, and its thickness is about 1 to 2 mm. The front surface of the polystyrene top plate 1 can also be provided with various convex decorative patterns 3 according to the different molding molds. In addition, in order to be more beautiful, the front surface of the polystyrene top plate 1 can also be printed with paint layers of different patterns.

[0013] The composite board 2 in the invention is preferably a lightweight composite wood or plastic board with a thickness of about 1 to 5 mm, and can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com