Thermoplastic composite material floor and preparation method and apparatus thereof

A composite material and thermoplastic technology, applied in the field of composite materials, can solve health hazards and other problems, and achieve the effects of no permanent deformation, short molding cycle and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

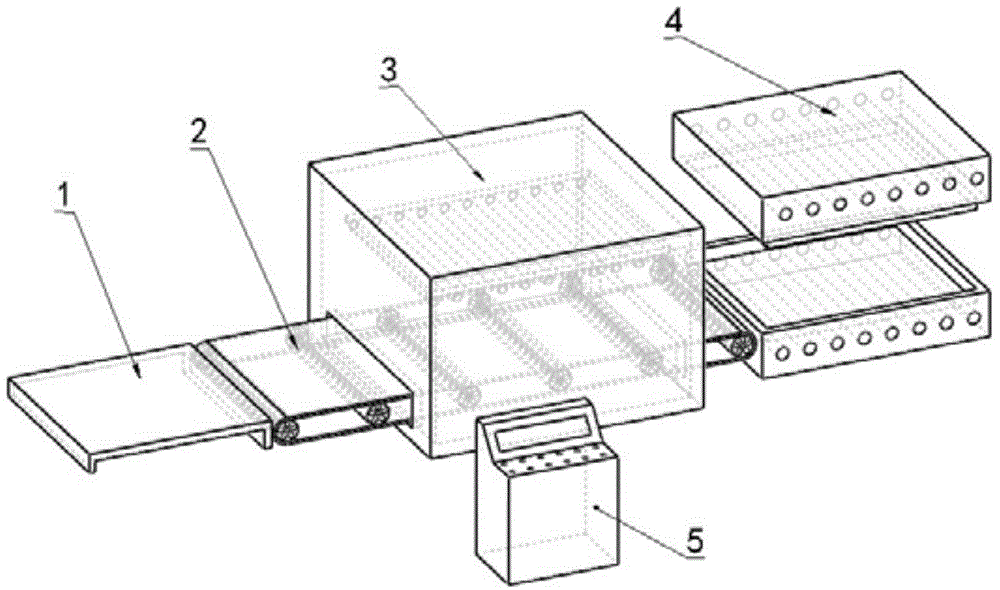

[0045] A kind of preparation method of thermoplastic composite material floor of the present invention, utilize as figure 1 The production device shown is prepared, comprising the following steps:

[0046] (1) Lay 20 layers of unidirectional continuous carbon fiber reinforced polyethylene prepreg tape (produced by Liaoning Liaojie Technology Co., Ltd.) according to 0 / 90, with a thickness of 5mm, in which the carbon fiber content is 30wt%, and the polyethylene content is 70wt%. Place it on the paving platform 1;

[0047] (2) Put the paved material into the infrared oven 3 for heating through the conveying device 2, heat for about 4 minutes to melt the resin, and control the temperature of the oven 3 to 160°C;

[0048] (3) Then quickly transfer the molten composite material to the mold 4 through the conveying device 2, pressurize and keep the pressure for cooling for 3 minutes, the temperature of the mold 4 is controlled at 50°C, and the pressure is controlled at 5MP;

[0049]...

Embodiment 2

[0053] A kind of preparation method of thermoplastic composite material floor of the present invention, utilize as figure 1 The production device shown is prepared, comprising the following steps:

[0054] (1) Stack 15 layers of hybrid fiber cloth woven by OCV's Twintex {polypropylene fiber (produced by Jiangsu Hengli Group) and glass fiber (produced by Zhejiang Jushi Group) mixed fiber yarn}, with a thickness of 8mm, and the content of polypropylene fiber is 50wt%, the glass fiber content is 50wt%, placed on the paving platform 1;

[0055] (2) Put the paved material into the infrared oven 3 for heating through the conveying device 2, heat for about 3 minutes to melt the resin, and control the temperature of the oven 3 to 170°C;

[0056](3) Then quickly transfer the molten composite material to the mold 4 through the conveying device 2, pressurize and keep the pressure for cooling for 8 minutes, the temperature of the mold 4 is controlled at 80°C, and the pressure is controll...

Embodiment 3

[0061] A kind of preparation method of thermoplastic composite material floor of the present invention, utilize as figure 1 The production device shown is prepared, comprising the following steps:

[0062] (1) Stack 20 layers of composite materials to a thickness of 8mm. The composite materials used are composite mixed fiber yarn braids with different continuous fiber orientations. The continuous fibers are carbon fibers (produced by Henan Yongmei Carbon Fiber Co., Ltd.) and basalt fibers (produced by Zhejiang Shijin Basalt Fiber Co., Ltd.) with a content of 55wt%, the matrix of the composite material is a mixed thermoplastic resin composed of nylon 6 and nylon 66 (produced by Jiangsu Haian Chemical Factory), with a content of 45wt%, placed on a pavement Material platform 1;

[0063] (2) Put the paved material into the infrared oven 3 for heating through the conveying device 2, heat for about 6 minutes to melt the resin, and control the temperature of the oven 3 to 220°C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com