Negative-pressure wind cuttings removal construction method for underground coalmine gas drainage borehole

A technology of gas drainage and gas drainage, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of large drilling sampling errors, affecting the working environment, and gas exceeding the limit, so as to improve construction speed and pumping The effect of prolonging mining life and improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

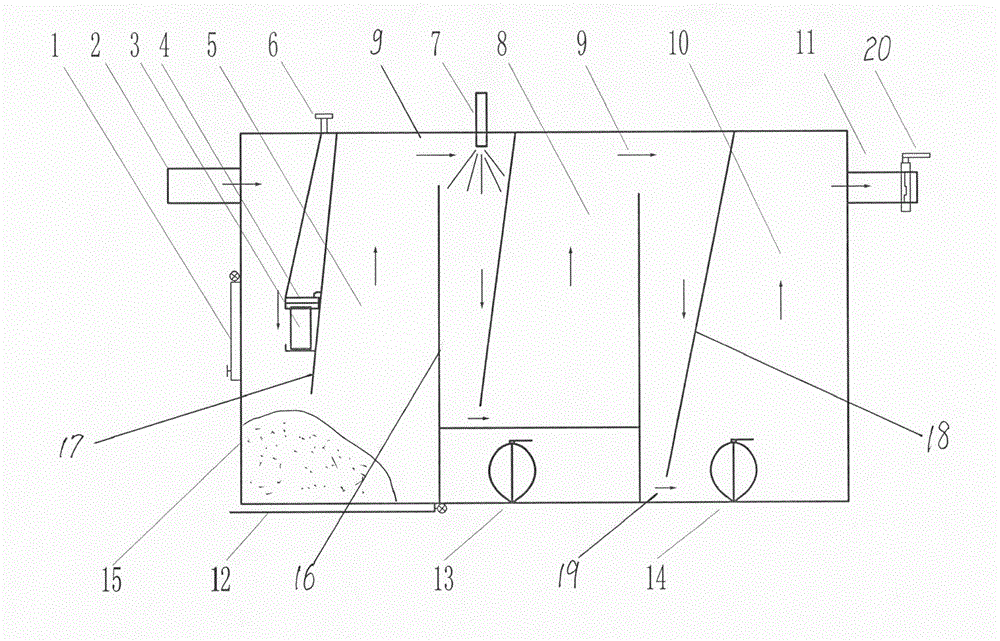

[0008] The actual operation schematic diagram of the inventive method is as attached figure 1 shown, it is Using a hollow chip removal alloy drill bit 1 and negative pressure wind, the drill chips drilled by the hollow chip removal drill bit 1 are sucked from the front groove of the drill bit under the action of negative pressure wind; the front end of the hollow chip removal drill bit 1 is hollowed out, the middle is hollow, and the connection On a large inner diameter hollow drill pipe 3 with an inner diameter of 60mm--70mm, a helical guide centralizer 2 is fixed on the large inner diameter hollow drill pipe 3 to guide the drill bit in the coal seam 4 so that the drill bit remains It runs in the center of the drill hole to avoid the deviation of the drill hole and ensure the quality of the drill hole; the hollow round drill pipe 3 with a large inner diameter is connected to a steel wire hose 6, and the steel wire hose 6 is connected to a cuttings separation device 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com