Mechanical follow-up oil cylinder assembly

A follow-up oil cylinder, mechanical technology, applied in the direction of mechanical equipment, fluid pressure actuators, servo motor components, etc., can solve the problems affecting the accuracy of the action, the system structure and layout of the follow-up control are complicated, and reduce the work intensity , The external oil circuit is simple and the function is perfect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

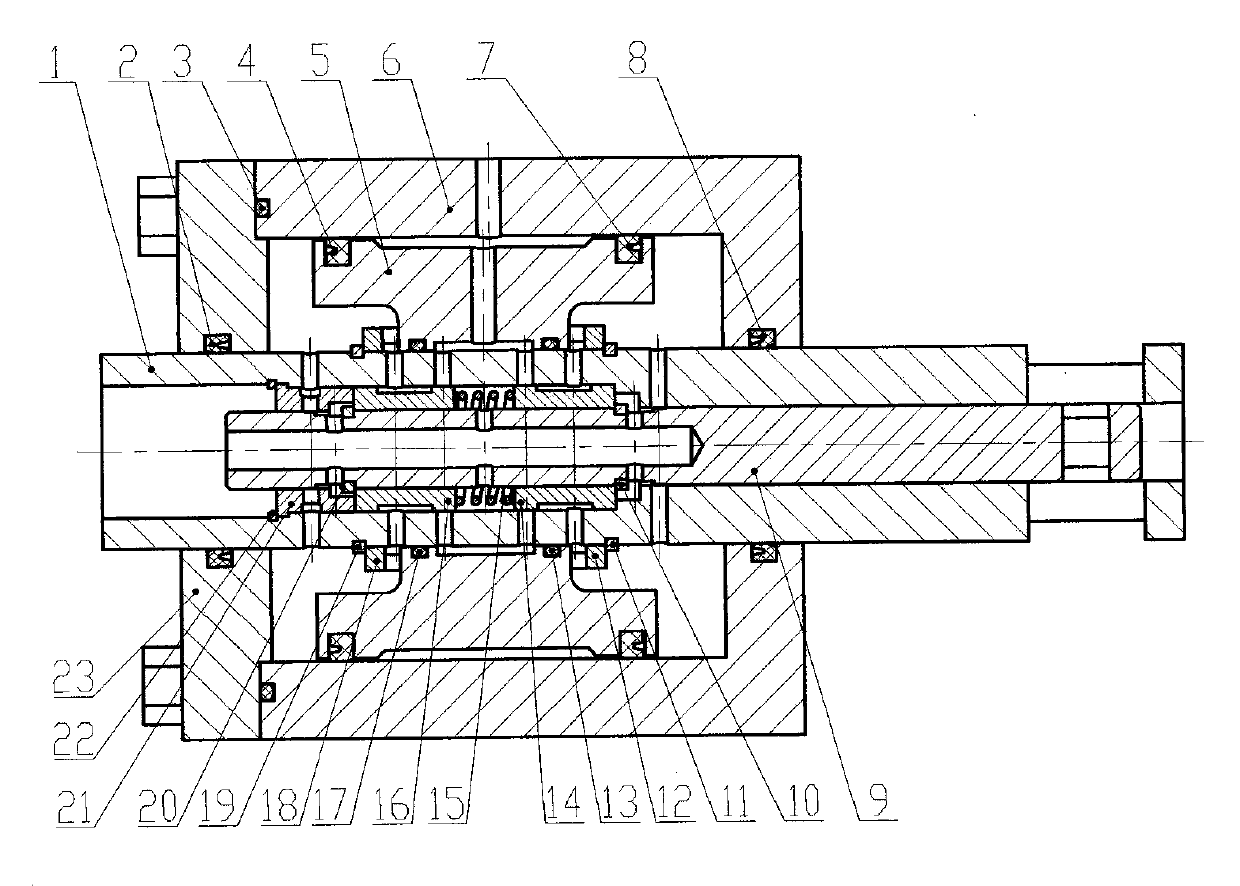

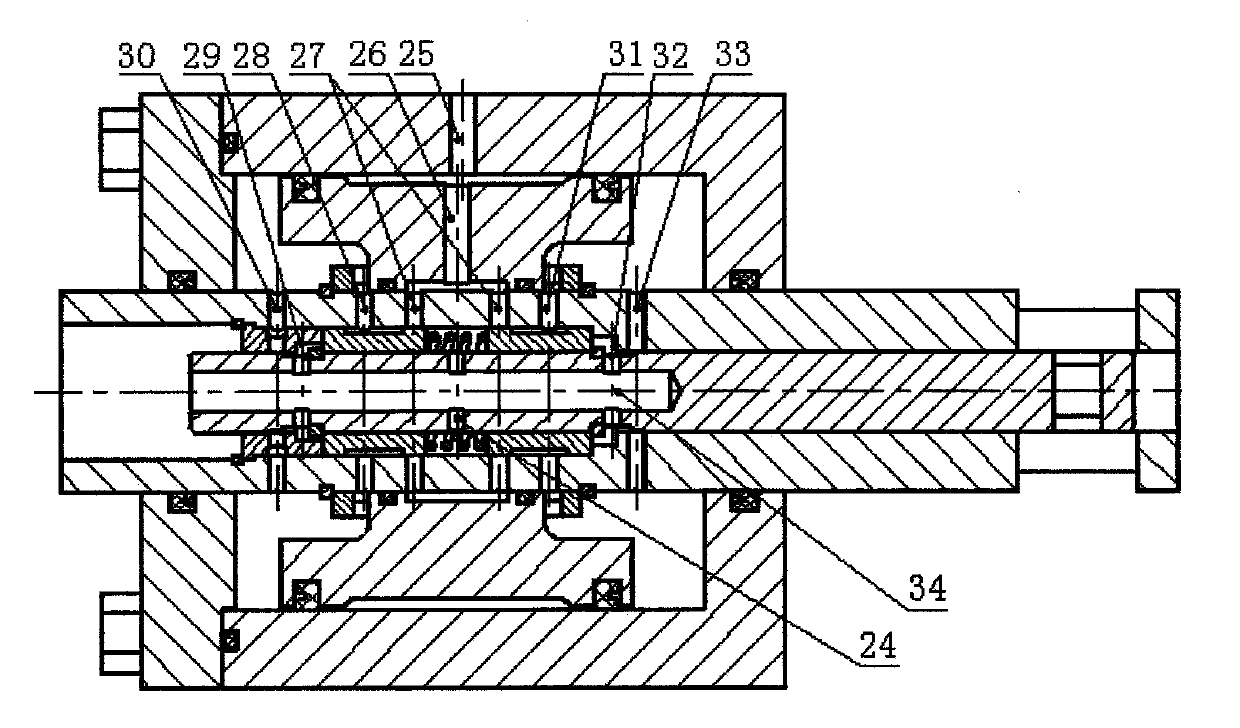

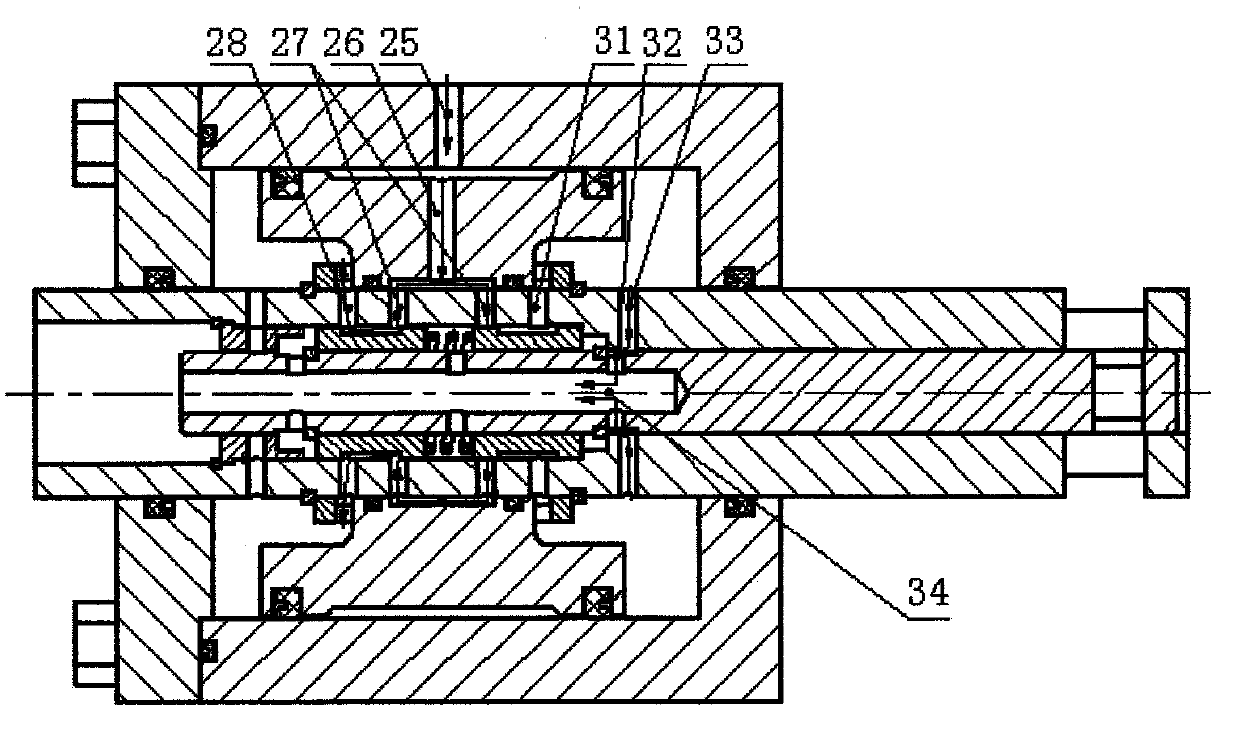

[0023] Embodiment of the present invention: a mechanical follow-up oil cylinder assembly, as attached Figure 1-2 As shown, it includes a cylinder block 6 with a straight-through hole or a stepped hole type. One end of the cylinder body 6 is connected to the cylinder head 23, and the piston assembly passes through the cylinder head 23 and the cylinder body 6 and is installed inside the cylinder assembly. There are two left and right chambers, and a control valve assembly is installed inside the piston assembly. The control valve stem 9 in the control valve assembly is connected to the shift block 24 on the follower, and the cylinder body 6, the piston assembly and the control valve assembly are respectively It is provided with an oil inlet hole, an oil control hole, an oil return hole and an oil discharge hole.

[0024] The piston assembly includes a piston rod 1 that runs through the cylinder body 6 and the cylinder head 23. A square connecting groove with a cross-sectional s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com