Scanning type light source testing system

A scanning light source and testing system technology, applied in the field of online scanning light source light intensity distribution and luminous flux testing system, can solve problems such as difficulty in meeting production line testing requirements, and achieve the effect of convenient query and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

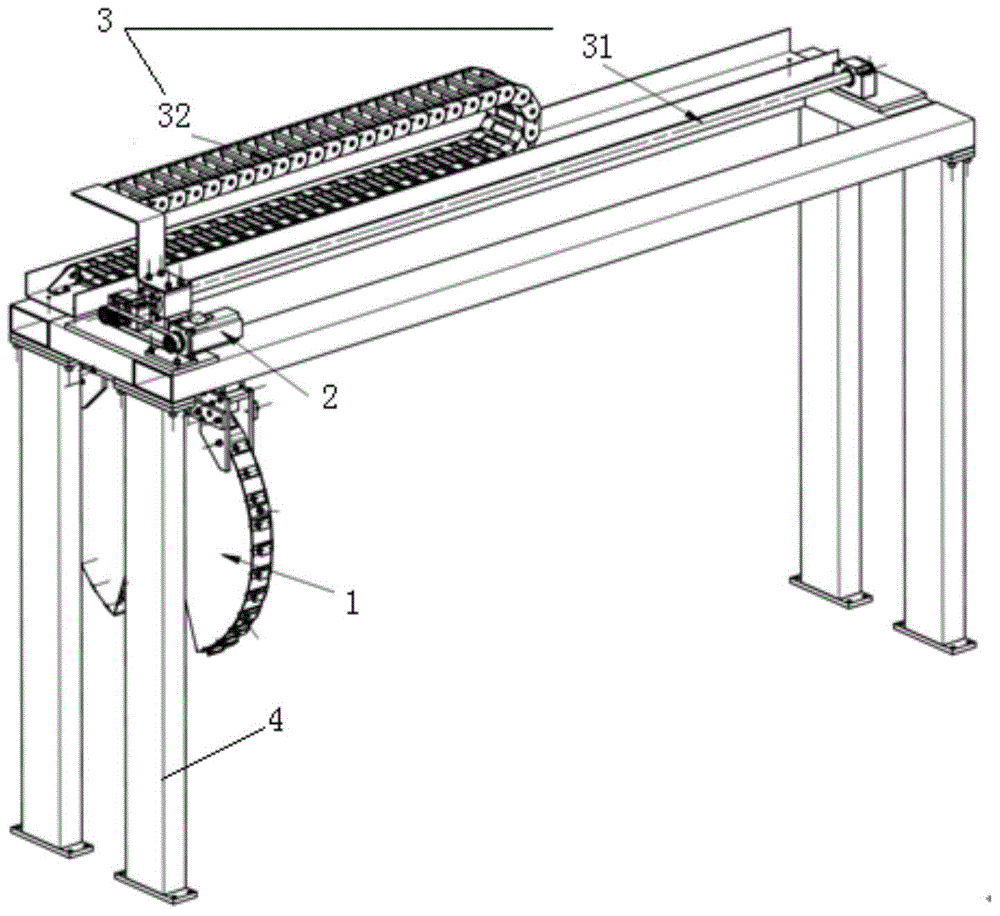

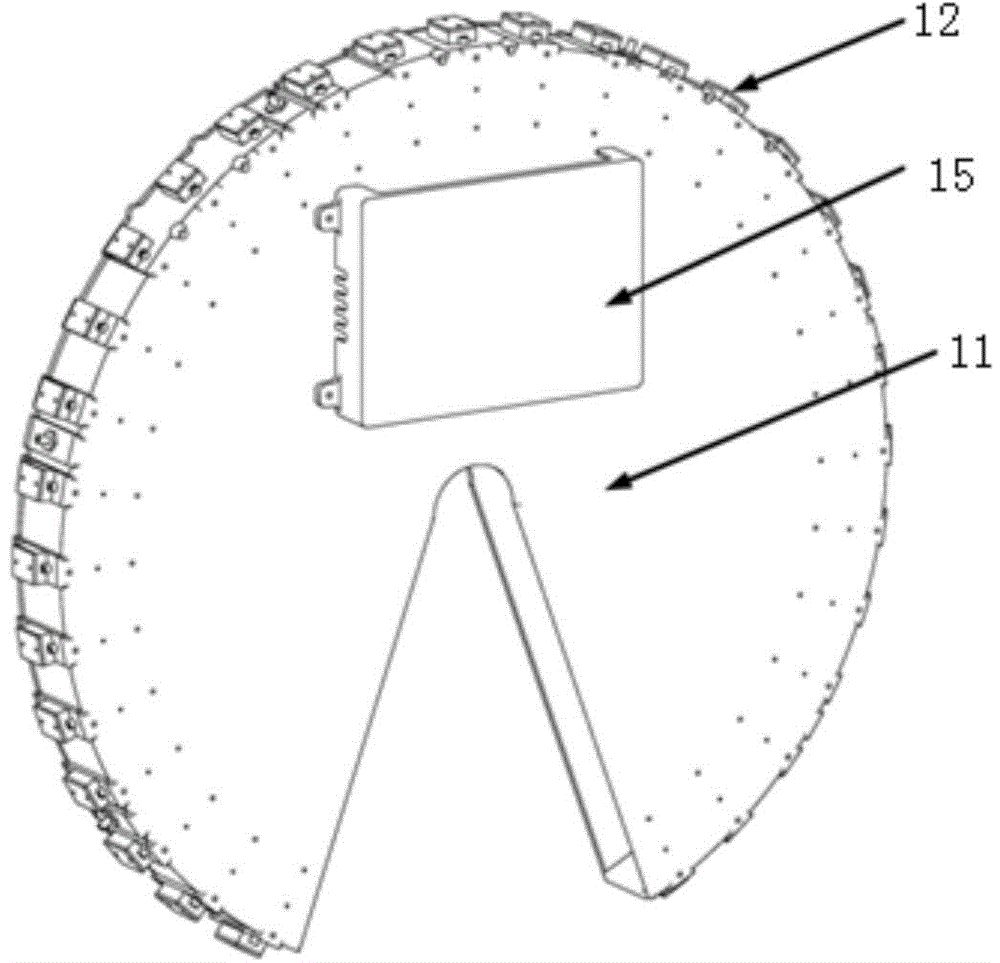

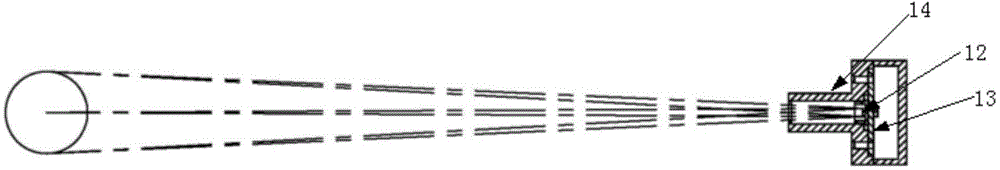

[0032] See figure 1 , a scanning light source testing system of the present embodiment comprises an optical test disk 1, a drive mechanism 2, a transmission mechanism 3 and a frame 4; the optical test disk 1, the drive mechanism 2 and the transmission mechanism 3 are all arranged on the frame 4; the driving mechanism 2 drives the transmission mechanism 3 to drive the optical test disc 1 to scan along the length direction of the light source to be tested; the optical test disc 1 includes a disc body 11 and a photoelectric sensor arranged on the arc surface of the disc body 11 12. The driving mechanism 2 is a motor; the transmission mechanism includes a ball screw 31 and a cable drag chain 32 . The optical test disc 1 is connected to the ball screw 31 through the connecting component, and the motor drives the ball screw 31 to move, so that the optical test disc 1 scans along the ball screw 31 to obtain light intensity test data, protected by the cable drag chain 32 The data ac...

Embodiment 2

[0036] Embodiment 2 is the first rotary scanning test system, such as Figure 4 As shown, the photoelectric sensor 12 is fixed on the disc body 11 by screws. Driven by the rotating motor, the photodetector 12 rotates by itself from 0° to 360° under the drive of the rotating motor, and the disc body 11 performs linear scanning operation. After completion, the distribution of light intensity within the entire solid angle range of the light source can be obtained.

Embodiment 3

[0038]Embodiment 3 is another rotary scanning test system. The photoelectric sensor 12 is fixed on the disc body 11 by screws. Driven by the rotating motor, the disc body 11 rotates from 0° to 360° to scan and simultaneously Driven by the driving mechanism to scan along the length direction of the light source to be measured, after the scanning is completed, the light intensity distribution within the entire solid angle range of the light source can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com