Power module with double radiators

A technology for power modules and heat sinks, which is applied in electric solid state devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problem that the heat dissipation requirements of high-power semiconductor chips cannot be met, the heat of semiconductor chips is not dissipated in time, and the power module is affected. Work performance and other issues, to achieve efficient and reliable long-term use, reduce the difficulty of layout manufacturing and welding process, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

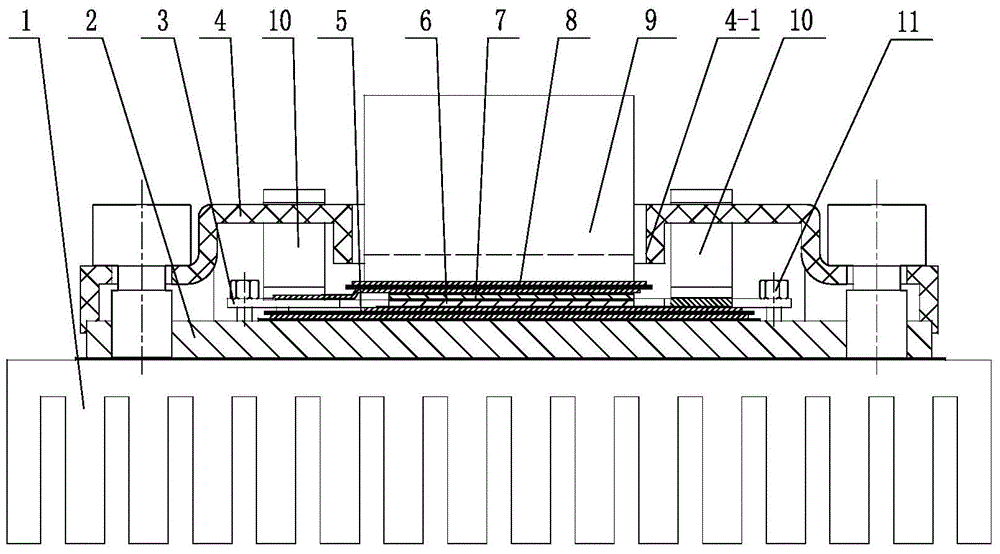

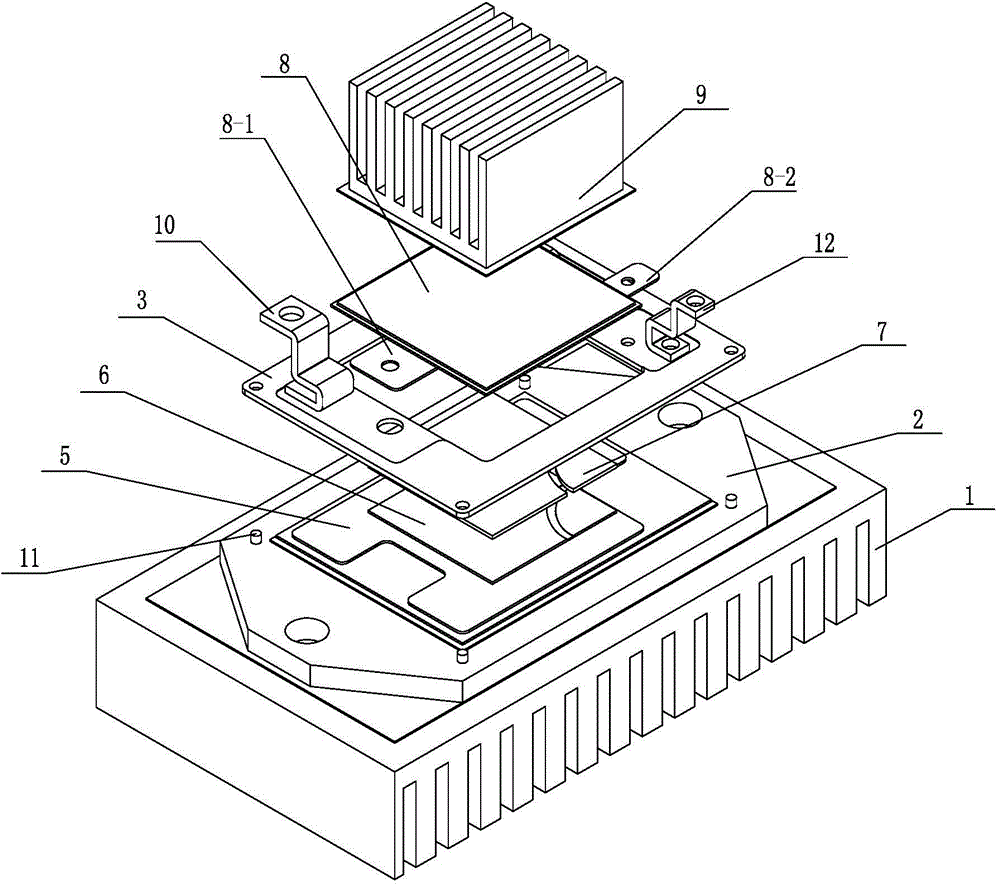

[0011] See figure 1 , 2 As shown, the power module with double heat sinks of the present invention includes a copper substrate 2, a metal-ceramic substrate and a semiconductor chip 6, and the semiconductor chip 6 can be a MOS transistor, an IGBT or a thyristor.

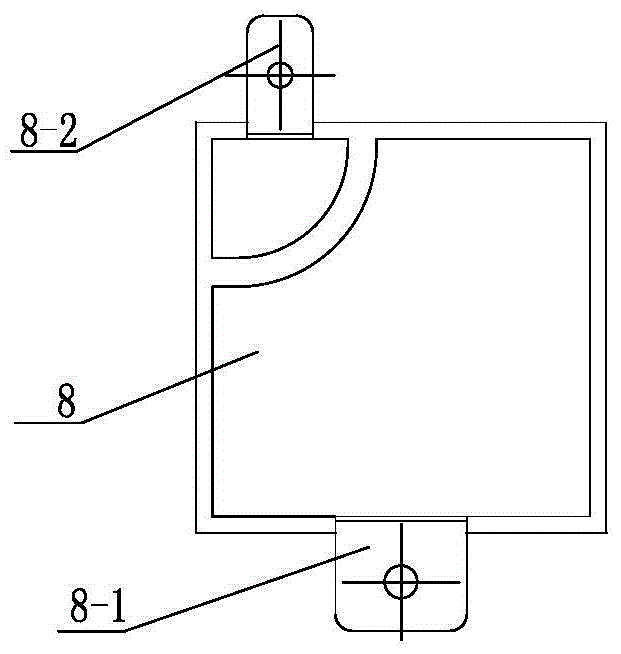

[0012] See figure 1 , 2 As shown, the cermet-clad substrate of the present invention comprises an upper cermet substrate 8 and a lower cermet substrate 5, and the upper cermet substrate 8 and the lower cermet substrate 5 are all composed of a ceramic layer and a metal ceramic layer covering the upper and lower sides of the ceramic layer. Metal layer structure, the underlying cermet substrate 5 is fixed on the copper substrate 2, and the underlying cermet substrate 5 can be welded on the copper substrate 2 by welding, and the copper substrate 2 is fixedly connected to the lower radiator 1, and the copper substrate 2 It can be fixed on the lower radiator 1 with thermal conductive adhesive, the connection area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com