Positive paste containing secondary-layer graphene and preparation method of positive paste

A positive electrode slurry and graphene technology, applied in graphene, battery electrodes, secondary batteries, etc., can solve problems such as personal injury, hidden dangers, heat dissipation, etc., to prolong battery life, improve safety, and increase thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

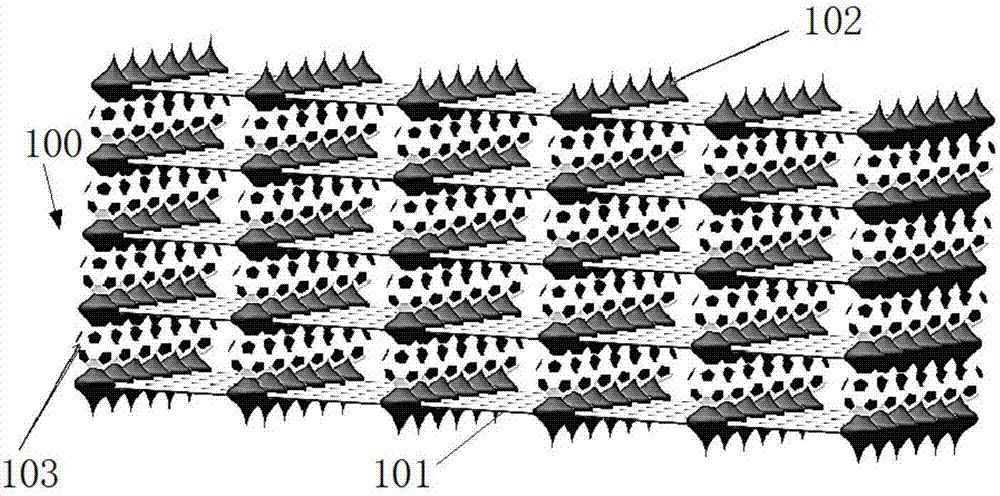

[0037] Embodiment 1: described lithium iron phosphate is 56%, described NMP is 24%, described PVDF is 2.5%, described SP is 16.5% and described sublayer graphene is 1.0%;

[0038] The weight ratio of described multilayer graphene sheet and described diamond is 18.5:1;

[0039] The number of layers of the multilayer graphene sheet is 5 layers, and the thickness of each layer of the multilayer graphene sheet is 0.5nm; the interlayer distance between two adjacent layers of the multilayer graphene sheet is 0.3 nm. nm;

[0040] The diamond is spherical carbon, and the particle size of the spherical carbon is 0.9nm.

Embodiment 2

[0041] Embodiment 2: the lithium iron phosphate is 59%, the NMP is 21.6%, the PVDF is 3.5%, the SP is 15% and the sublayer graphene is 0.9%;

[0042] The weight ratio of described multilayer graphene sheet and described diamond is 18:1;

[0043] The number of layers of the multi-layer graphene sheet is 4 layers, and the thickness of each layer of the multi-layer graphene sheet is 0.4nm; the interlayer distance between two adjacent layers of the multi-layer graphene sheet is 0.2 nm. nm;

[0044] The diamond is spherical carbon, and the particle size of the spherical carbon is 0.7nm.

Embodiment 3

[0045] Embodiment 3: the lithium iron phosphate is 58.1%, the NMP is 21%, the PVDF is 3.2%, the SP is 17% and the sublayer graphene is 0.7%;

[0046] The weight ratio of described multilayer graphene sheet and described diamond is 18.7:1;

[0047] The number of layers of the multilayer graphene sheet is 3 layers, and the thickness of each layer of the multilayer graphene sheet is 0.2nm; the interlayer distance between two adjacent layers of the multilayer graphene sheet is 0.4 nm. nm;

[0048] The diamond is spherical carbon, and the particle size of the spherical carbon is 1.6 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com