Semiconductor temperature difference generation device

A thermoelectric power generation and semiconductor technology, applied in the direction of mufflers, exhaust devices, generators/motors, etc., can solve the problems of temperature difference reduction, hot water temperature drop, semiconductor power generation chip hot end temperature drop, etc., to achieve stable power generation performance Reliable and guarantee the effect of converting technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

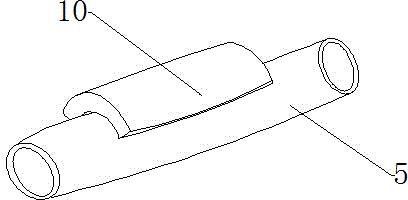

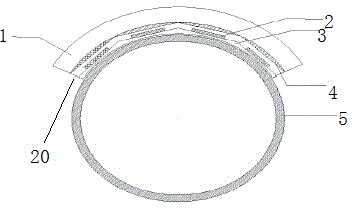

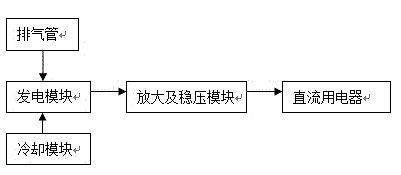

[0020] The invention relates to a semiconductor thermoelectric power generation device, such as figure 1 Shown: the semiconductor thermoelectric power generation device 10 is installed between the three-way catalytic oxidizer of the automobile exhaust pipe 5 and the primary muffler of the automobile exhaust pipe 5; figure 2 , 3 As shown: the semiconductor thermoelectric power generation device 10 includes an external heat sink 1, a semiconductor power generation chip 20 provided with several semiconductor thermoelectric module devices 2 arranged in parallel, and an amplification and voltage stabilization circuit. The voltage output terminals are connected, and the semiconductor power generation chip 20 is covered in the outer heat sink 1 . The semiconductor temperature difference power generation device of the present invention ensures the high-efficiency conversion technical indicators of the power generation device, and the power generation performance is stable and reliab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com