Poly(phenylene ether) composition, article, and method

A technology of phenylene ether and composition, which is applied in poly(phenylene ether) composition, products and fields, and can solve problems such as discouraging or prohibiting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

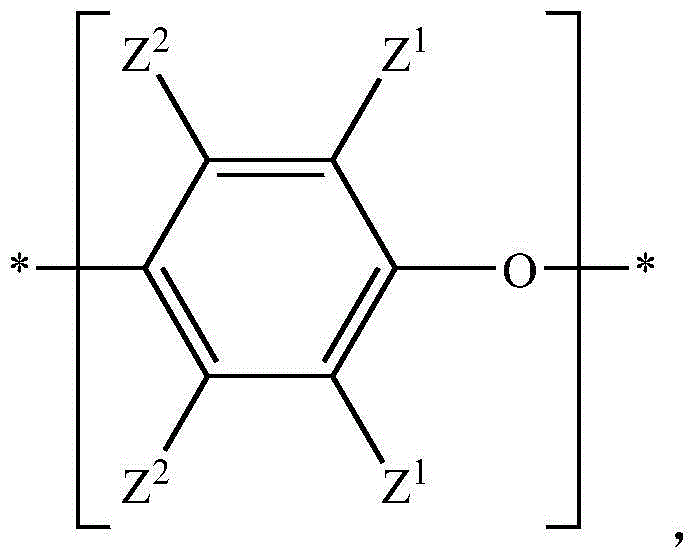

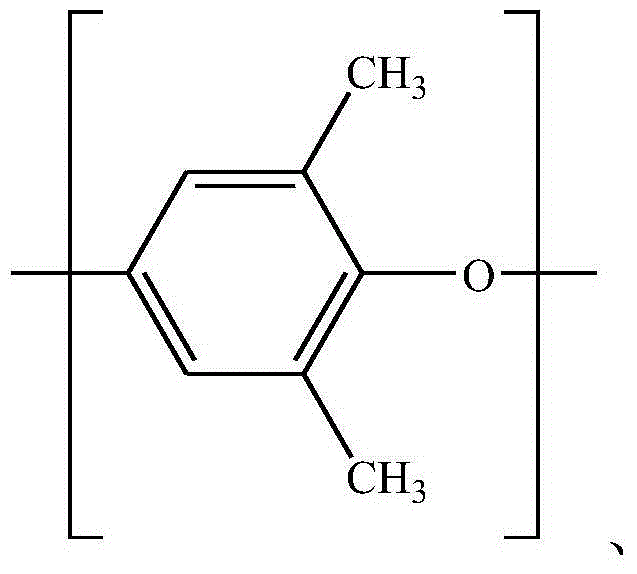

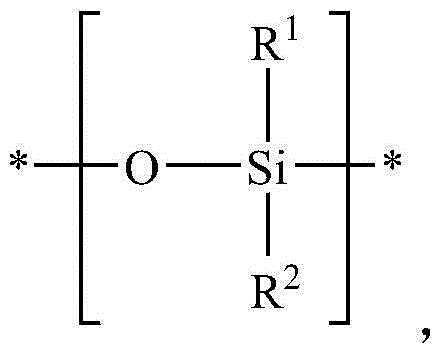

[0073] Embodiment 1: A composition comprising: 60 to 95 weight percent of poly(phenylene ether)-poly A siloxane block copolymer reaction product; and 5 to 40 weight percent of an impact modifier; wherein the impact modifier comprises a poly(alkenyl aromatic) component and a rubber component, and wherein the poly(alkenyl aromatic compound) The weight ratio of the base aromatic compound) component to the rubber component is at least 0.5; wherein the composition comprises 1 to 10 weight percent of covalently bonded poly(phenylene ether)-polysiloxane block copolymer Polysiloxane; wherein, relative to 100 parts by weight of polysiloxane covalently bonded in poly(phenylene ether)-polysiloxane block copolymer, the composition comprises less than or equal to 10 parts by weight Polysiloxanes non-covalently bonded in poly(phenylene ether)-polysiloxane block copolymers; wherein the composition comprises less than or equal to 0.5 weight percent organophosphate; wherein the composition co...

Embodiment approach 2

[0074] Embodiment 2: A composition according to Embodiment 1 showing V at a sample thickness of less than or equal to 3.0 mm in the 20 mm vertical burning flame test of Underwriters Laboratories Certification 94 "Tests for Flammability of Plastic Materials, UL 94" -1 or V-0 flammability rating, heat deflection temperature of at least 128°C determined according to ASTM D 648-07 using 1.82 megapascal (MPa) stress and 3.2 mm sample thickness, and at 23°C according to ASTM D 256-10 A notched Izod impact strength of at least 150 J / m determined using a pendulum energy of 2.7 J and an impact velocity of 3.5 m / s.

Embodiment approach 3

[0075] Embodiment 3: The composition according to Embodiment 1 or 2, further comprising 4 to 15 weight percent of an inorganic filler selected from the group consisting of clay, mica, talc, and combinations thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| logarithmic viscosity | aaaaa | aaaaa |

| logarithmic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com