A kind of proton exchange membrane fuel cell electrocatalyst and preparation method thereof

A technology of proton exchange membrane and electrocatalyst, which is applied in the direction of battery electrodes, catalyst carriers, chemical instruments and methods, etc., can solve the problems of not being able to meet large-scale commercial applications, low stability, high activity, etc., and achieve energy saving, particle size Good uniformity and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

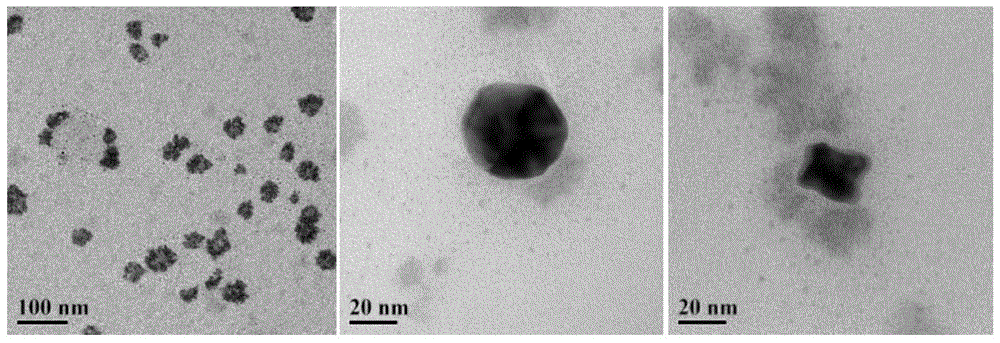

Embodiment 1

[0053] 1) Add 4.5mg of KBr powder and 8.4mg of KCl powder into 4.0ml of 10mM CTAC aqueous solution with stirring at room temperature until completely dissolved;

[0054] 2) Add 7.5ml of 5.0mM K2PdCl4 aqueous solution to 1), keep stirring and raise the temperature to 80°C;

[0055] 3) Add 0.75ml of 50mM ascorbic acid aqueous solution, the reduction reaction starts, control the reaction time to 3h, and obtain the second metal nano-seed that exists stably in the form of colloid;

[0056] 4) At room temperature, add 22.5ml of 5mM H2PtCl6Pt aqueous solution to the colloidal solution of the second metal nano-seed, heat up to 100°C under continuous stirring and reflux, and start the replacement reaction, and react for 24 hours to cool down to room temperature to obtain a porous, hollow wall. Colloidal solution of Pt3Pd nanoseeds.

[0057] 5) Loading and sedimentation of platinum-based catalyst nanoparticles

[0058] A Add 40mg of KB-300 purified by 0.5M HCl, 60°C, and 3h to the col...

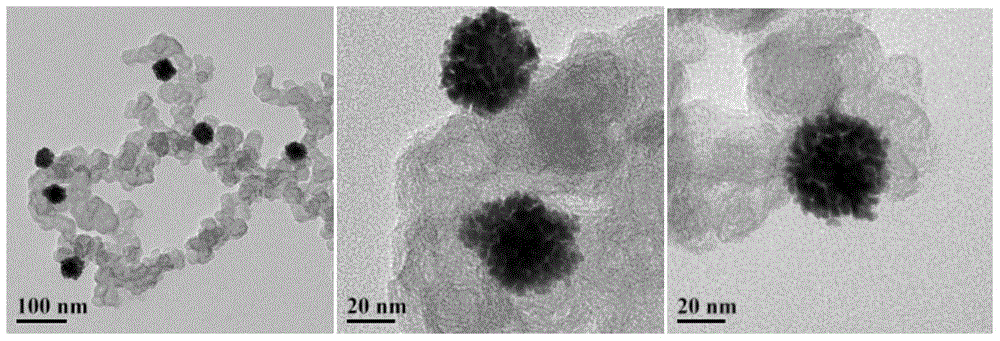

Embodiment 2

[0067] 1) Add 2.0mg of NaBr powder and 11mg of NaCl powder into 9.4ml of 20mM PVP aqueous solution with stirring at room temperature until completely dissolved;

[0068] 2) Add 7.5ml of 5.0mM Cu(NO3)2 aqueous solution to 1), keep stirring and control the reaction temperature to 25°C;

[0069] 3) Add 0.75ml of 50mM oxalic acid aqueous solution, the reduction reaction starts, control the reaction time to 3h, and obtain the second metal nano-seed that exists stably in the form of colloid;

[0070] 4) At room temperature, add 22.5ml of 10mM K2PtCl4 aqueous solution to the colloidal solution of the second metal nano-seed, keep stirring and control the temperature of the reaction system at 25°C, start the displacement reaction, react for 20h, and obtain porous wall, hollow Pt3Pd nano Colloidal solution of seeds.

[0071] 5) Loading and sedimentation of platinum-based catalyst nanoparticles

[0072] A Add 395mg of Vulcan XC-72 purified by 0.5M HNO3, 80°C, and 5h to the colloidal so...

Embodiment 3

[0077] 1) Add 41mg of CTAB powder and 18mg of CTAC solid into 5.6ml of 20mM SDBS aqueous solution with stirring at room temperature until completely dissolved;

[0078] 2) Add 7.5ml of 5.0mM NiCl2 aqueous solution to 1), keep stirring and raise the temperature to 40°C;

[0079] 3) Add 0.6ml of 50mM ascorbic acid aqueous solution, the reduction reaction starts, control the reaction time to 2h, and obtain Ni nano-seeds that exist stably in the form of colloids;

[0080] 4) At room temperature, add 25ml of 3mM PtCl4 aqueous solution to the colloidal solution of Ni nano seeds, keep stirring and control the temperature of the reaction system to 40°C, start the replacement reaction, and react for 5h to room temperature to obtain porous, hollow Pt2Ni nanoparticles. Colloidal solution of seeds.

[0081] 5) Loading and sedimentation of platinum-based catalyst nanoparticles

[0082] A Add 34 mg of BP2000 purified by 0.5M HCl, 60 °C, and 8 h to the colloidal solution of PtNI nano-seeds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com