Production technology for ultra-thin antibacterial spunlace surgery wiping material

A wiping material and production process technology, applied in the field of textile materials, can solve the problems of difficult observation of wound size and condition, affect the liquid absorption and air permeability of surgical drapes, and reduce the comfort of patients, etc., to achieve good longitudinal drainage performance, The effect of excellent drapability and good liquid absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

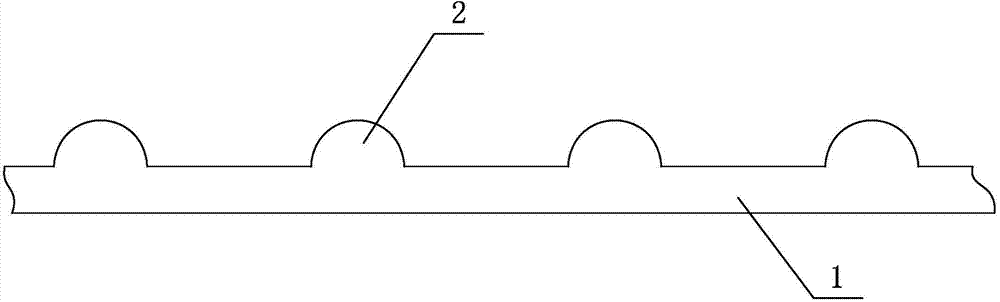

Image

Examples

Embodiment 1

[0032] The production process of the ultra-thin antibacterial spunlace operation wiping material of the present invention specifically includes the following: select the mixed fiber of hydrophilic polyester fiber and viscose fiber as the raw material, and feed it into a long curtain, a horizontal opener, and a large bin cotton mixing box in sequence ; Then, the fine opener 1 and the fine opener 2 carry out layering treatment, and the raw materials processed by the fine opener 1 are sequentially fed into the cotton storage box 1, the air cotton box 1, the carding machine 1, and the cross-lapper 1. Drafting machine, the raw materials processed by the second fine opening machine are sequentially fed into the second cotton storage box, the second air cotton box, and the second carding machine; then the two layers of raw materials are stacked, and then enter the spunlace process and antibacterial treatment in turn process, drying process, on-line inspection process, coiling proc...

Embodiment 2

[0043] The production process of the ultra-thin antibacterial spunlace operation wiping material of the present invention specifically includes the following: select the mixed fiber of hydrophilic polyester fiber and viscose fiber as the raw material, and feed it into a long curtain, a horizontal opener, and a large bin cotton mixing box in sequence ; Then, the fine opener 1 and the fine opener 2 carry out layering treatment, and the raw materials processed by the fine opener 1 are sequentially fed into the cotton storage box 1, the air cotton box 1, the carding machine 1, and the cross-lapper 1. Drafting machine, the raw materials processed by the second fine opening machine are sequentially fed into the second cotton storage box, the second air cotton box, and the second carding machine; then the two layers of raw materials are stacked, and then enter the spunlace process and antibacterial treatment in turn process, drying process, on-line inspection process, coiling proc...

Embodiment 3

[0054] The production process of the ultra-thin antibacterial spunlace operation wiping material of the present invention specifically includes the following: select the mixed fiber of hydrophilic polyester fiber and viscose fiber as the raw material, and feed it into a long curtain, a horizontal opener, and a large bin cotton mixing box in sequence ; Then, the fine opener 1 and the fine opener 2 carry out layering treatment, and the raw materials processed by the fine opener 1 are sequentially fed into the cotton storage box 1, the air cotton box 1, the carding machine 1, and the cross-lapper 1. Drafting machine, the raw materials processed by the second fine opening machine are sequentially fed into the second cotton storage box, the second air cotton box, and the second carding machine; then the two layers of raw materials are stacked, and then enter the spunlace process and antibacterial treatment in turn process, drying process, on-line inspection process, coiling proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com