Water-saving washing machine and control method

A technology for water-saving washing machines and washing machines, which is applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems of no flushing system, increased cost, easy blockage of filters, etc., to reduce maintenance frequency, prolong service life, Simple and easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

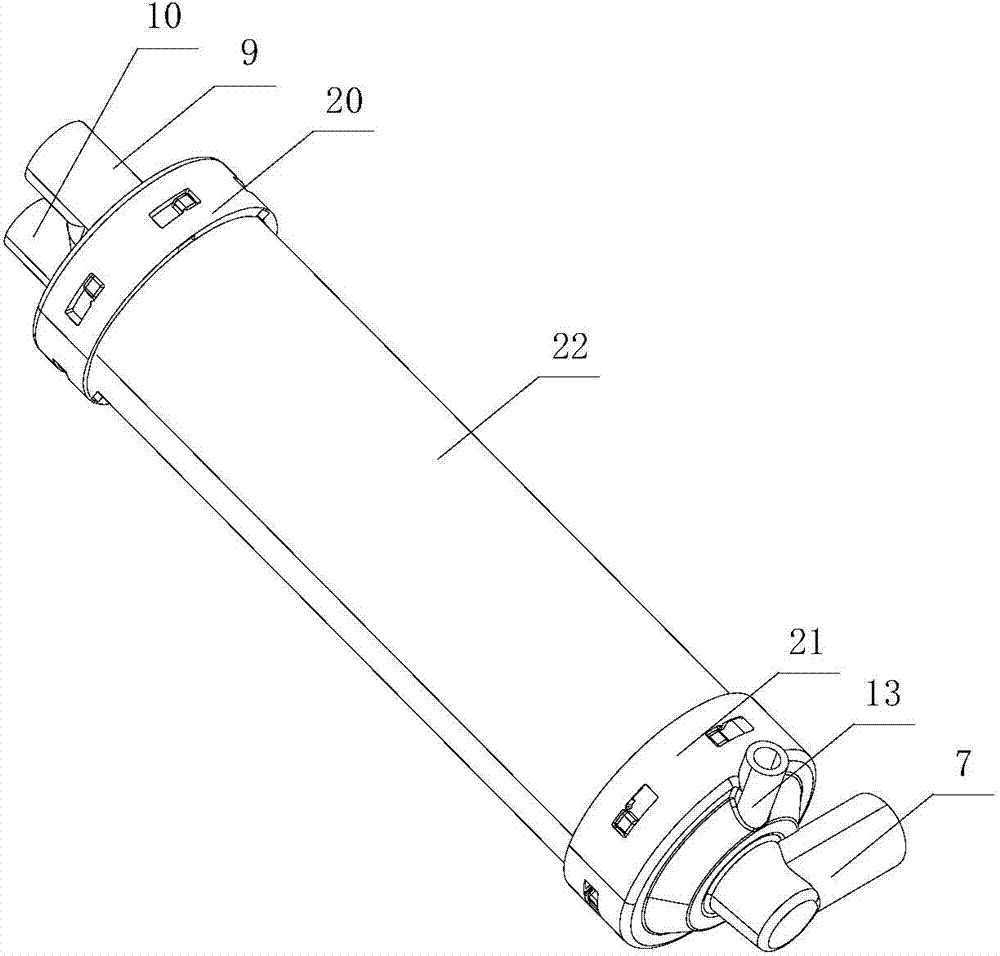

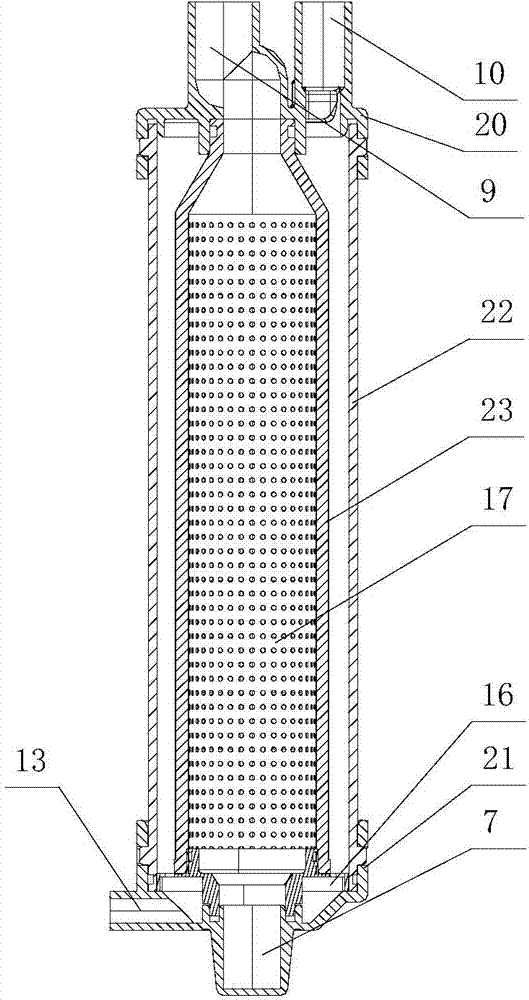

[0070] Such as figure 2 , image 3 , Figure 4 As shown, the pre-filter 6 in this embodiment includes an outer cylinder wall 22, an upper end cover 20 and a lower end cover 21 at both ends of the outer cylinder wall 22, the outer cylinder wall 22 is a hollow cylinder, and a filter screen support frame is arranged inside 23. The filter screen support frame 23 is covered with a filter screen 17. The upper end cover 20 and the lower end cover 21 of the pre-filter 6 are fixed by rotation through the buckle structure, and there are anti-loose protrusions at the buckle. The pre-filter 6 , Sealing rings are set at the joints of each component to ensure smooth flow of each pipeline without mixed flow. The pre-filter 6 is provided with a first inlet 7 before the filter screen 17, a first outlet 9 is provided before the filter screen 17, and a second outlet 10 is provided after the filter screen 17, wherein the inlet is located on the end cover at one end, and the outlet is located a...

Embodiment 2

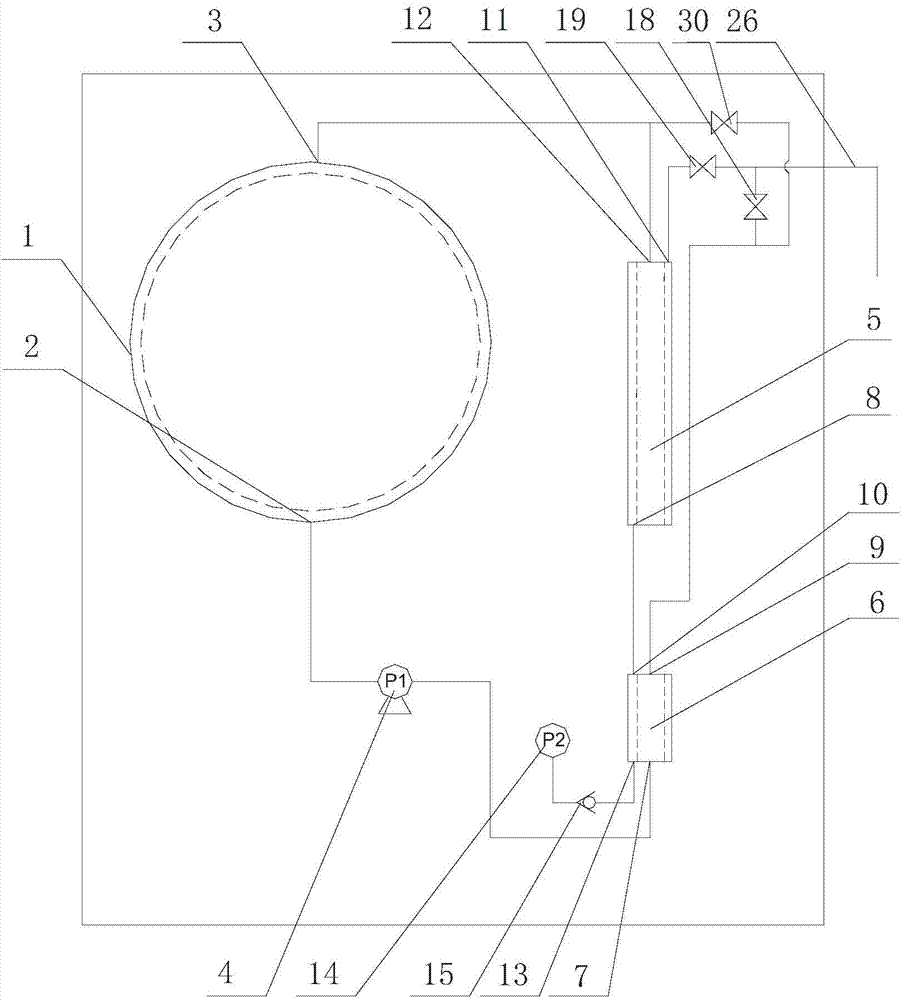

[0073] Such as figure 1 , Figure 5 As shown, the cleaning method described in this embodiment is specifically: open the air pump 14 and the second valve 19, the gas generated by the air pump 14 enters the pre-filter 6 through the third inlet 13, is discharged through the second outlet 10, and passes through the second inlet 8 enters the main filter 5, is discharged through the third outlet 13, and is discharged through the second valve 19 through the drain pipe 26 of the washing machine. The gas generates bubbles in the water, and the movement, explosion or vibration of the bubbles will affect the pre-filter 6 and the main filter 5. The filter screen is air-washed, and after 10s-120s, close the air pump 14 and the second valve 19, open the drain pump 4 and the first valve 18, the water flow enters the pre-filter 6 through the first inlet 7, and is discharged through the first outlet 9. The filter screen 17 of the pre-filter 6 is washed by water flow, and the water flow toget...

Embodiment 3

[0075] Such as figure 1 , Figure 6 As shown, the cleaning method described in this embodiment is specifically: open the air pump 14 and the first valve 19, the gas generated by the air pump 14 enters the pre-filter 6 through the third inlet 13, is discharged through the second outlet 10, and passes through the first valve. 18 is discharged through the drain pipe 26 of the washing machine, the gas generates bubbles in the water, and the air-washing of the filter screen 17 of the pre-filter 6 is carried out by the movement, explosion or vibration of the bubbles. After 10s-120s, the air pump 14 is turned off, the drain pump 4 is turned on, and the water flows through The first inlet 7 enters the pre-filter 6, and is discharged through the first outlet 9. The filter screen 17 of the pre-filter 6 is washed by the washing of the water flow, and the water flow together with the filtered lint and granular impurities pass through the first valve. 18 is discharged through the washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com