Floor heat preservation construction process achieved through ultrafine inorganic fiber spraying

A technology of inorganic fiber spraying and construction technology, applied in the direction of heat preservation, building components, sound insulation, etc., can solve the problems of increased input cost, many seams, easy aging and deformation, etc., and achieves the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

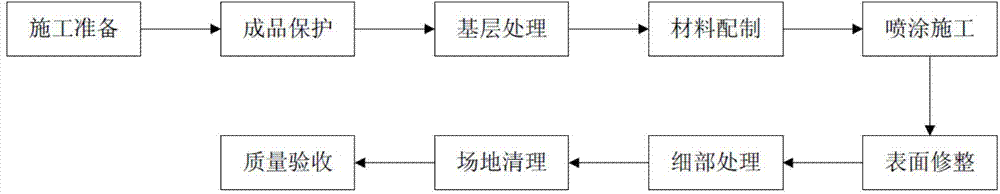

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A kind of superfine inorganic fiber spraying floor insulation construction technology, including the following construction steps:

[0034] (1), construction preparation:

[0035] Conduct on-site inspection of the inorganic fiber cotton and water-based environmental protection adhesive that enter the site and take samples for retest according to regulations. layer, no foaming, no deterioration and discoloration;

[0036] (2), finished product protection:

[0037] Cover the water supply and drainage, fire protection pipes, air ducts and cable bridges that have been constructed on site, and mark and protect the strong and weak electric boxes reserved on the roof of the basement;

[0038] (3), grass-roots treatment:

[0039] Clean up the dust, dirt and residual ash on the surface of the base, level the high protrusions on the surface of the base, and use 1:2.5 cement mortar to fill up the honeycomb, pitted surface, exposed ribs, and loose parts layer by lay...

Embodiment 2

[0057] Embodiment 2 A kind of superfine inorganic fiber spraying floor insulation construction technology, is characterized in that, comprises the following construction steps:

[0058] (1), construction preparation:

[0059] Conduct on-site inspection of the inorganic fiber cotton and water-based environmentally friendly adhesives that enter the site, and take samples for retesting according to regulations. layer, no foaming, no deterioration and discoloration;

[0060] (2), finished product protection:

[0061] Cover the water supply and drainage, fire protection pipes, air ducts and cable bridges that have been constructed on site, and protect the strong and weak electric boxes reserved on the roof of the basement;

[0062] (3), grass-roots treatment:

[0063] Clean up the dust, dirt and residual ash on the surface of the base, level the high protrusions on the surface of the base, and use 1:2.5 cement mortar to fill up the honeycomb, pitted surface, exposed ribs, and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com