Profile model-based geometric correction method for optical projection tomography imaging system

An optical projection tomography and imaging system technology, applied in the field of image processing, can solve problems such as image artifacts, achieve the effect of reducing artifacts and improving spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

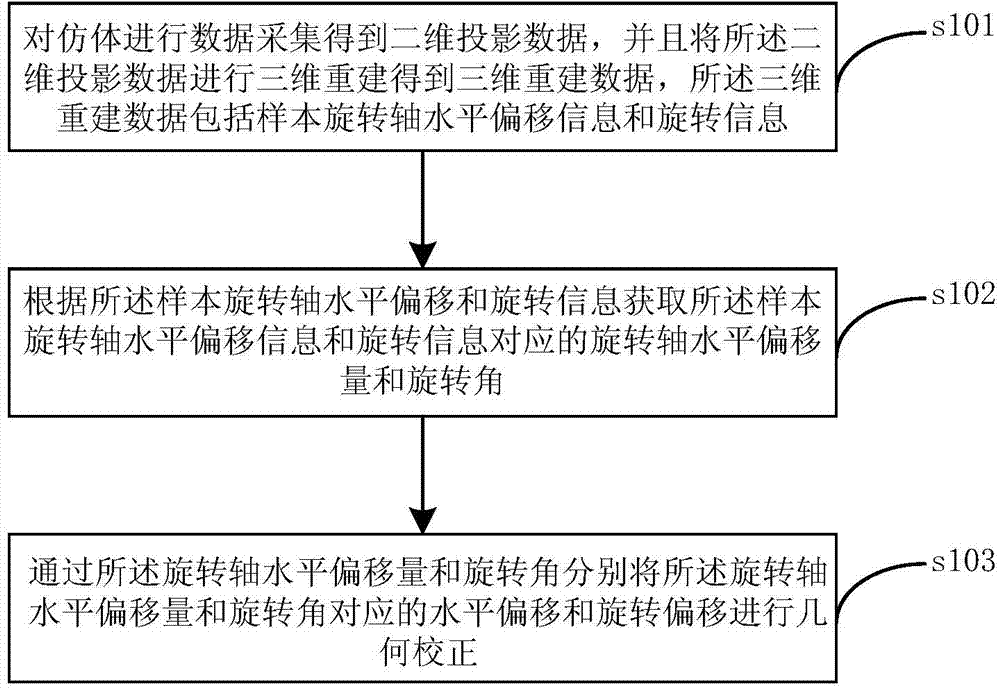

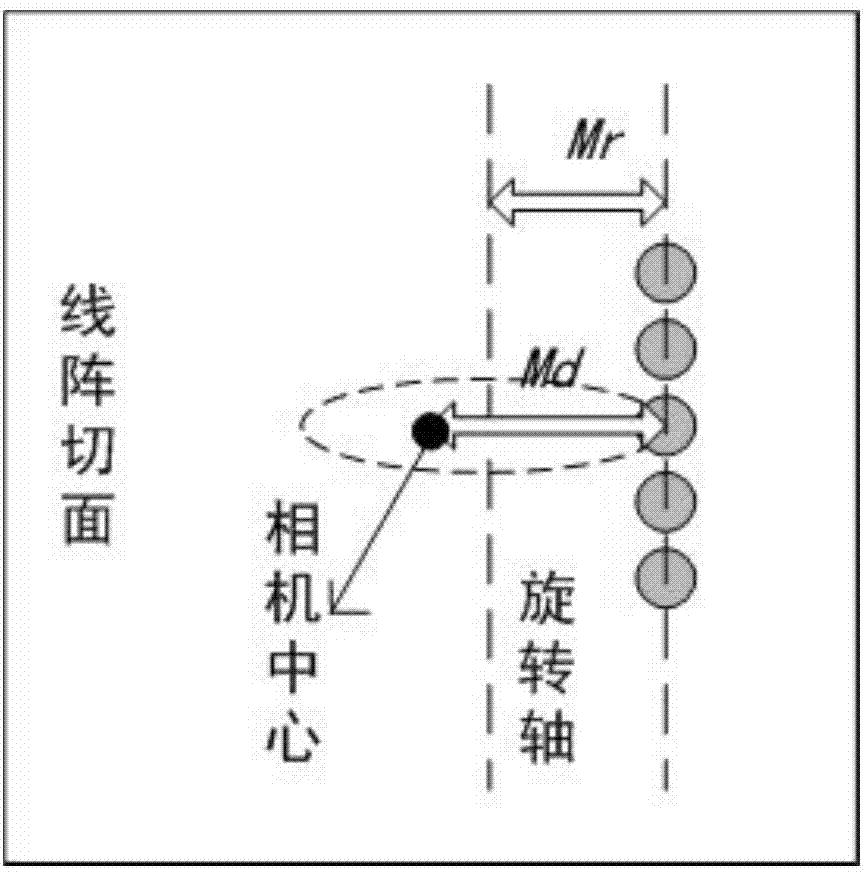

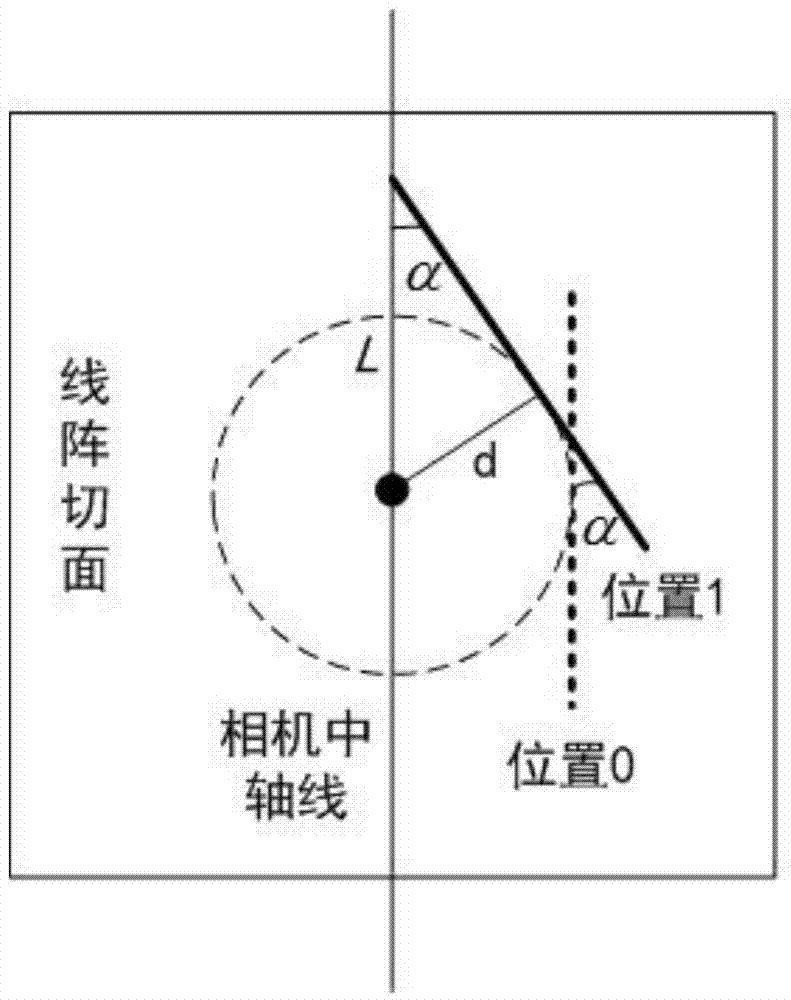

[0014] The general idea of the present invention is to obtain the horizontal offset and rotation angle of the rotation axis corresponding to the horizontal offset information and rotation information of the sample rotation axis according to the horizontal offset and rotation information of the sample rotation axis, and obtain the horizontal offset and rotation angle according to the horizontal offset of the rotation axis The horizontal offset of the rotation axis and the horizontal offset and rotation offset corresponding to the rotation angle are geometrically corrected respectively, so as to improve the spatial resolution of the optical projection tomography system and reduce image artifacts.

[0015] The geometric correction method of the phantom-based optical projection tomography system provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0016] figure 1 It is a flowchart of a geometric corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com