Wiring pile head convenient to manufacture in batched mode

A wiring pile head, batch technology, applied in the direction of connection, conductive connection, substation/switch layout details, etc., can solve the problems of slow production process of wiring pile head, short effective service life, long production cycle, etc., to improve the reliability of power supply , Convenient for mass production, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

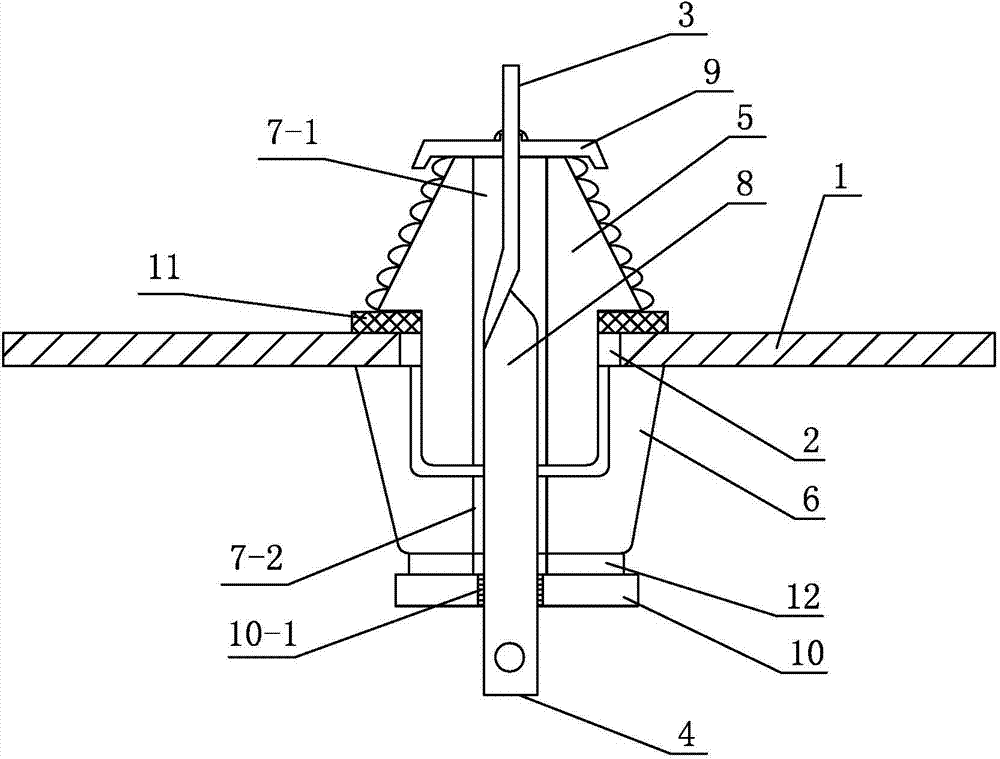

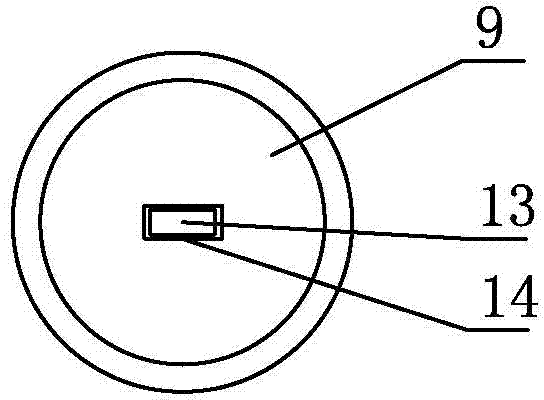

[0025] figure 1 Among them, the technical solution of the present invention provides a wiring pile head that is convenient for mass production, including an insulating porcelain bottle arranged at the outlet opening 2 of the switch box box body 1 and a conductor passing through the insulating porcelain bottle, which is located at the outlet of the switch box. The conductor outside the box body at the opening constitutes the external terminal 3 of the switch box, and the conductor inside the box at the outlet opening of the switch box constitutes the internal terminal 4 of the switch box; its invention points are:

[0026] The insulating porcelain bottle includes a combined upper insulating porcelain bottle 5 and a lower insulating porcelain bottle 6 which are snapped together with upper and lower parts;

[0027] The upper insulating porcelain bottle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com