Automatic inoculation machine suitable for mushroom sticks

A technology of inoculating machine and fungus stick, which is applied in application, horticulture, and botanical equipment and methods, etc., can solve the problems of poor consistency of fungus state and non-uniform size of fungus block, and achieves reduction of production cost and simple and ingenious structure. , the effect of low infection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

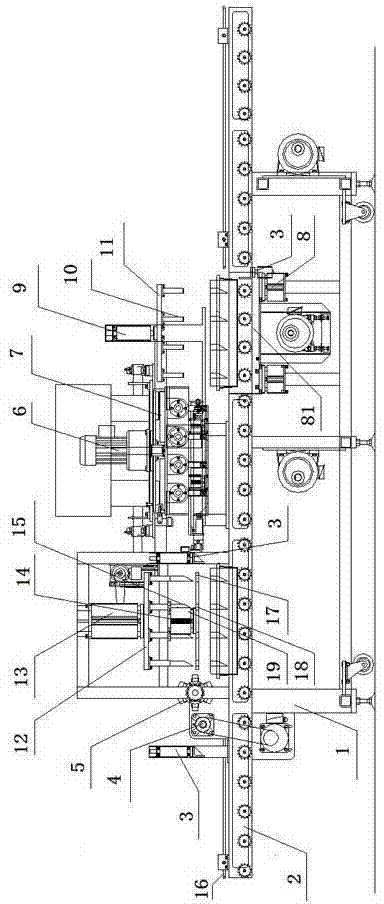

[0047] Embodiment 1, with reference to figure 1 -2, an automatic inoculation machine suitable for bacteria sticks, the inoculation machine includes a frame 1, and a bacteria stick conveying mechanism 2, a punching device and an inoculation machine are installed on the frame 1;

[0048] Described punching device is installed on the top of bacterium rod conveying mechanism 2, and punching device comprises punching power mechanism 13, punching rod 15, punching connecting plate 12 and positioning mechanism 14; On the power output of the power mechanism 13, the punching rod 15 is fixed on the punching connecting plate 12; the positioning mechanism 14 includes a positioning power mechanism 19 installed on the frame 1, and a power output connected to the positioning power mechanism 19. The positioning plate 17 on the top; the positioning plate 17 is provided with several through holes 18 that cooperate with the punching rod 15 for the punching rod 15 to pass through;

[0049] On the...

Embodiment 2

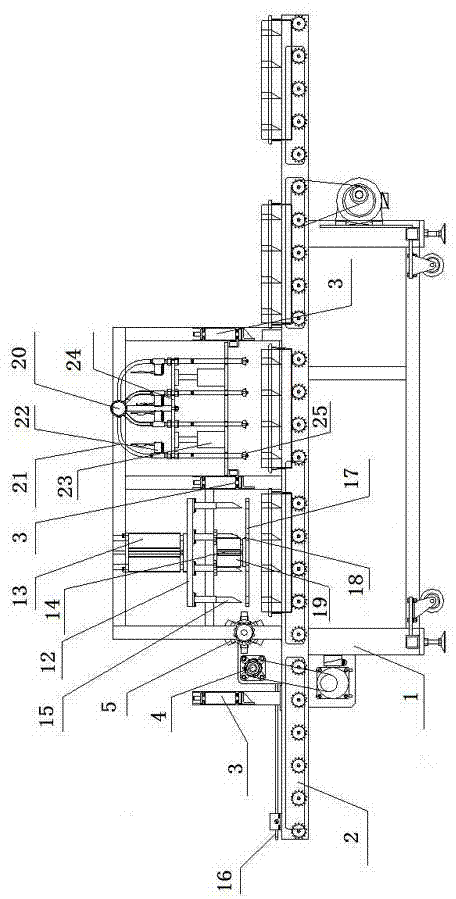

[0051] Embodiment 2, with reference to figure 2 , in the automatic inoculation machine that is applicable to bacterium rod described in embodiment 1: described liquid strain inoculation machine comprises liquid strain distributor 20, and liquid strain distributor 20 passes strain delivery pipeline 21 and inoculation nozzle 25 connection, the strain conveying pipeline 21 is fixed on the inoculation connecting plate 24, and the strain conveying pipeline 21 is provided with a solenoid valve 22, and the inoculating lifting power mechanism 23 is connected on the inoculating connecting plate 24, and the inoculating lifting power machine 23 is installed on the machine. Rack 1.

Embodiment 3

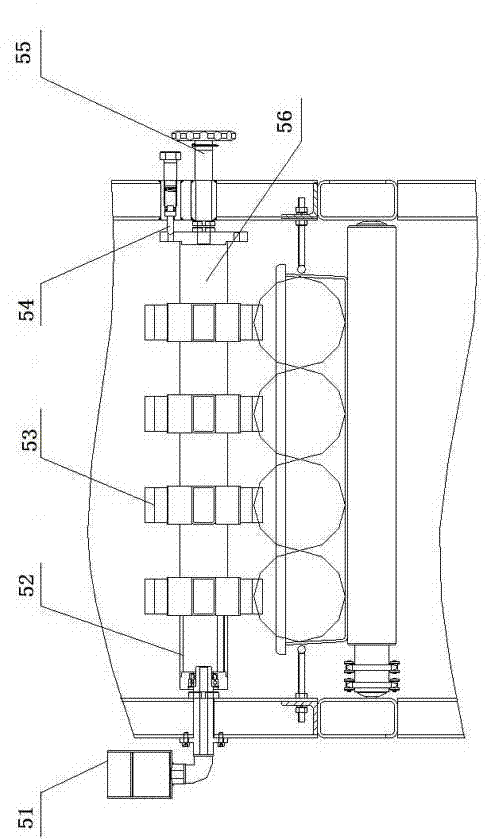

[0052] Embodiment 3, with reference to figure 1 , Figure 4 -6, in the automatic inoculation machine suitable for bacteria sticks described in Example 1: the solid strain inoculation machine 7 includes a feeding mechanism, a moving feeding mechanism, a jacking mechanism and a pounding mechanism;

[0053] Described feeding mechanism comprises the spawn plate 71 that is installed on the frame 1, is provided with some bacteria stick grooves in the spawn plate 71, is provided with cutter head 73 and scraping rotating disc 74 below the spawn plate 71, The cutterhead 73 and the scraping rotating disk 74 are all connected with the feeding power mechanism 6, and the cutterhead 73 is provided with several cutterhead scrapers 72 and cutterhead blanking openings; The feed chute 711 on the top is provided with several feed trough discharge openings 712 in the feed trough 711, and the bottom of the feed chute discharge opening 712 is provided with a feed outlet 713, and each feed chute di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com