Device for peeling tentacles of squid employing enzymic method

A technology of enzymatic peeling and squid whiskers, applied in application, food preparation, food science, etc., can solve the problems of long peeling time and low processing efficiency, and achieve short enzymatic hydrolysis and cleaning time, less replacement times and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

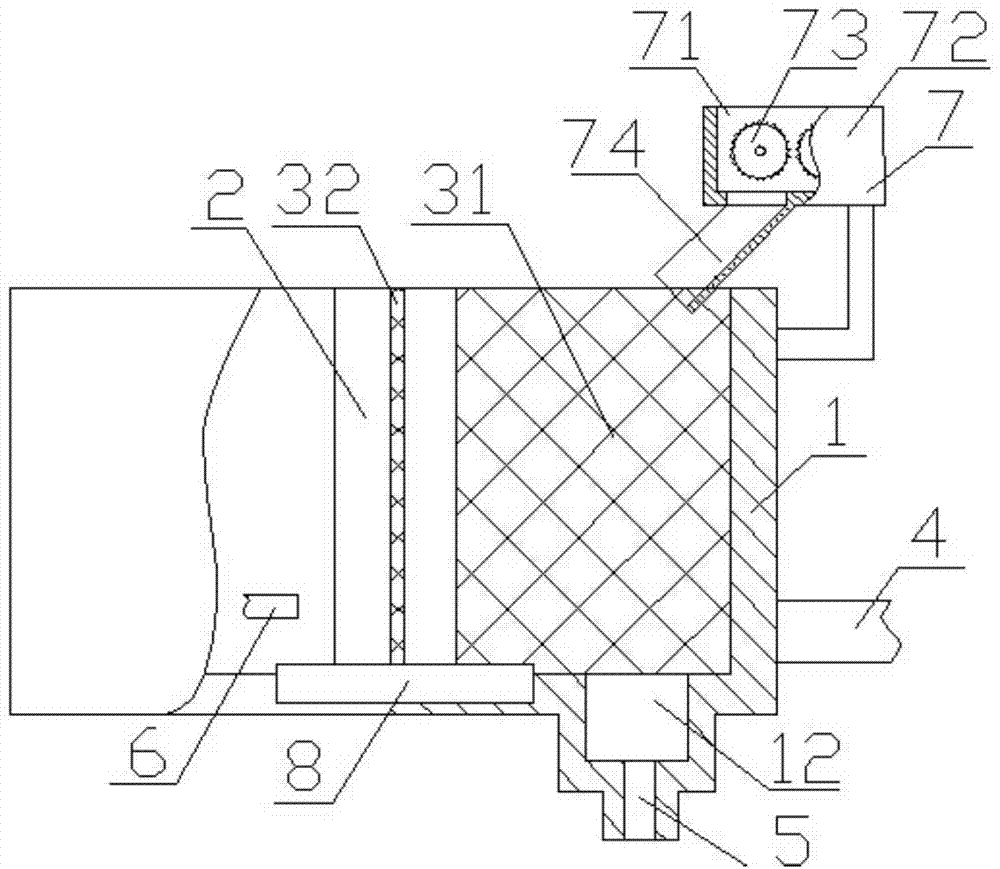

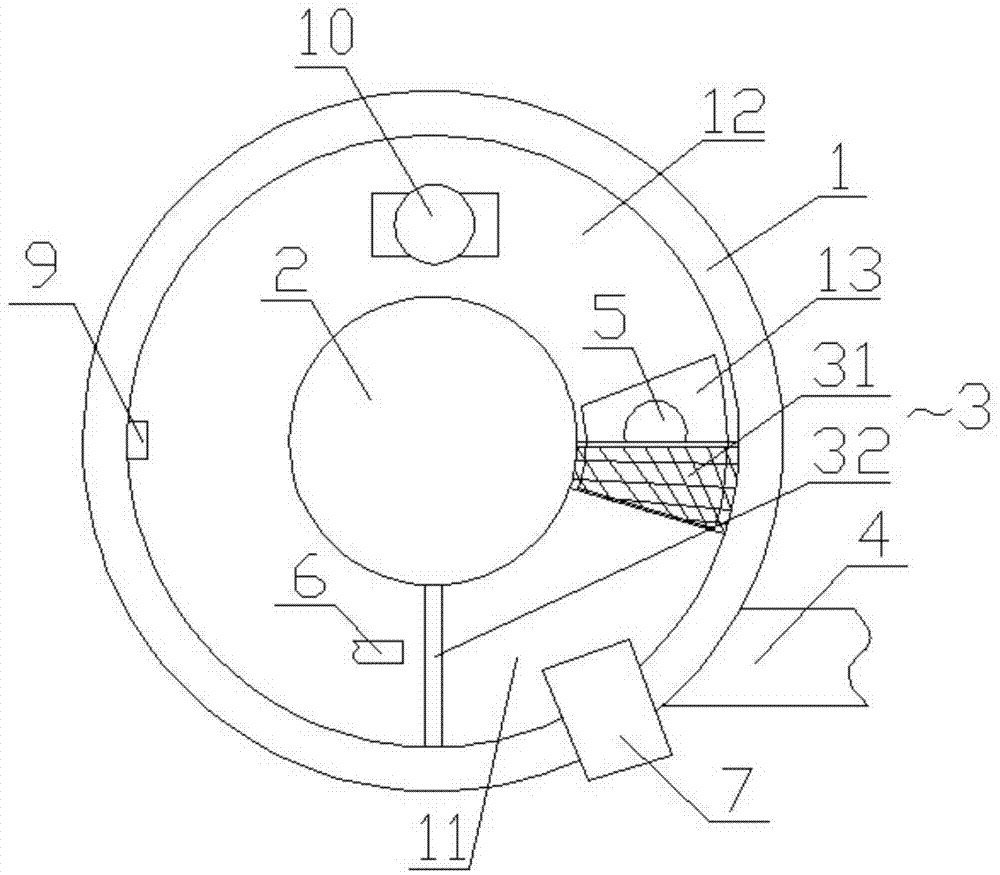

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 1 , figure 2 As shown, a squid whisker enzymatic peeling device includes an enzymatic hydrolysis tank 1, an island-shaped boss 2 is arranged in the middle of the bottom wall of the enzymatic hydrolysis tank, and two partitions are connected between the island-shaped boss and the side wall of the enzymatic hydrolysis tank. The filter screen 3, two partition screens and the island-shaped boss divide the inner chamber of the enzymolysis tank into two chambers, one of which is the raw material chamber 11 for containing squid silk to be peeled, and the other is a circulation chamber 12. A submersible pump 10 is provided in the circulation chamber, and a cleaning water inlet pipe 4 and a waste water discharge pipe 5 leading to the raw material chamber are provided on the enzymolysis tank; one of the two partition screens is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com