Tobacco product heated without burning

A heat-not-burn technology for tobacco products, applied in the field of tobacco, can solve problems such as hot sensation, smoke burning, and high temperature in the heating chamber, and achieve the effects of reducing the burning sensation, disappearing the hot feeling, and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

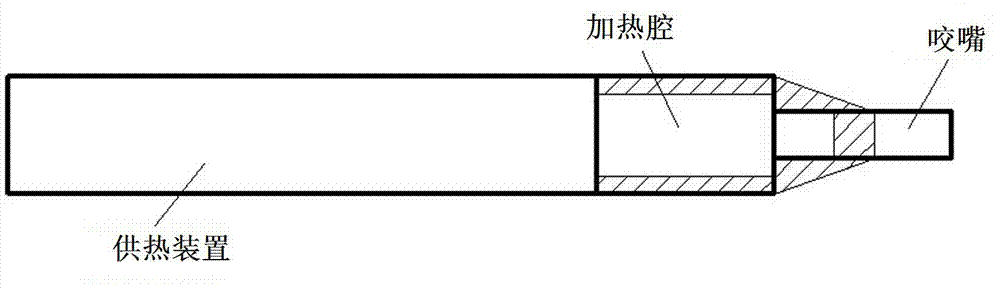

[0031] like figure 1 As shown, the heat-not-burn tobacco product provided by the present invention includes a sequentially connected heat supply device, a heating chamber and a mouthpiece; phase-change heat storage materials can be added around the heating chamber, inside the mouthpiece and / or around the mouthpiece; wherein "Around" in around the heating cavity and around the mouthpiece refers to the outer circumference, figure 1 The filled part in is only a schematic illustration of the area where the phase change heat storage material can be added.

[0032] Weigh 6.81 grams of KCl, 3.19 grams of ZnCl 2 After melting at high temperature and stirring evenly, add it to the stainless steel inner cylinder around the heating cavity of the heat-not-burn tobacco product; then weigh 7.3 grams of Na 2 HPO 4 12H 2 O, 1.9 grams of urea, 0.8 grams of CaSO 4 2H 2 O, Stir and melt at 70°C, put it in an ice bath to crystallize, repeat melting and crystallization 5 times, then put it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com